Accelerate Innovation with Rapid Prototyping Service

Transform ideas into tangible prototypes faster than ever with our Rapid Prototyping Service. Whether you’re testing functionality, refining designs, or pitching to stakeholders, speed and precision matter. Here’s how we deliver:

- ✅Lightning-Fast Turnaround: Deliver prototypes in days, not weeks, to keep projects on track.

- ✅Material Versatility: Work with plastics, metals, composites, and more to match your product’s needs.

- ✅Cost-Efficient Iterations: Test multiple designs affordably before committing to full production.

- ✅Expert Support: Collaborate with engineers to optimize prototypes for performance and manufacturability.

Stop wasting time on delays. Let our Rapid Prototyping Services bridge the gap between concept and reality—so you can innovate with confidence.

What is Rapid Prototyping Definition?

Define of Rapid prototyping meaning is a transformative manufacturing process that accelerates product development by quickly turning digital designs into physical models. By leveraging advanced technologies like 3D printing, CNC machining, vacuum casting, and injection molding, company can validate designs, test functionality, and iterate faster—means reducing time-to-market by up to 70% compared to traditional methods.

At Yigu Technology in China, we specialize in end-to-end rapid prototyping solutions tailored to your needs. Whether you’re refining a concept, securing investor buy-in, or preparing for mass production, China Yigu Technology bridges the gap between innovation and reality.

How Does Rapid Prototyping Work?

Rapid prototyping is a game-changer in product development, enabling businesses to transform ideas into tangible models quickly and iteratively. But how does it actually work, and how can company leverage this technology effectively? At Yigu Technology manufacturer, we specialize in streamlining the rapid prototyping process to help clients innovate faster, reduce costs, and bring products to market ahead of the competition.

1. Seamless Digital-to-Physical Workflow

Our rapid prototyping begins with 3D CAD modeling, where our engineers collaborate closely with clients to refine designs digitally. Using advanced software, we simulate functionality, test ergonomics, and optimize aesthetics before physical production. Once approved, we deploy cutting-edge 3D printing technologies (SLA, SLS, FDM) or CNC machining to create high-fidelity prototypes with precision down to micrometers. This digital-first approach minimizes errors and accelerates turnaround times.

2. Material Innovation for Real-World Testing

Yigu Technology offers a wide range of materials—from durable plastics and metals to flexible resins—to match your prototype’s intended use. Whether you need a heat-resistant component for industrial testing or a consumer-grade prototype for user feedback, our material expertise ensures your model performs as expected in real-world scenarios.

3. Iterative Design and Fast Feedback Loops

The true power of rapid prototyping lies in iteration. We produce prototypes in days, not weeks, allowing clients to test, refine, and retest designs diagram rapidly. Our agile process supports last-minute adjustments, ensuring your final product aligns perfectly with market demands.

4. End-to-End Support for Scalability

Beyond prototyping, Yigu Technology assists with low-volume production and manufacturing handoff, bridging the gap between concept and commercialization. Our team provides guidance on design for manufacturability (DFM) to avoid costly delays during mass production.

Rapid Prototyping Applications

Rapid prototyping has revolutionized how businesses bring ideas to life, enabling faster iteration, cost savings, and risk reduction. At Yigu Technology manufacturers, we specialize in applying rapid prototyping to solve complex challenges across diverse sectors. Here’s how we empower industries to innovate efficiently:

Automotive & Transportation

Develop ergonomic dashboards, lightweight components, and functional engine parts with high-strength materials. Test durability, aerodynamics, and user experience before mass production.

Consumer Electronics

Create sleek, user-friendly device casings, touchscreen prototypes, and internal circuit boards. Validate form factors, heat dissipation, and wireless connectivity early in the design cycle.

Medical & Healthcare

Produce patient-specific surgical guides, biocompatible implants, and wearable device mockups. Accelerate FDA approvals with realistic, functional prototypes for clinical testing.

Industrial & Manufacturing

Optimize machinery parts, jigs, and fixtures for precision manufacturing. Reduce downtime by testing tooling designs virtually and physically before full-scale production.

Consumer Goods & Toys

Design interactive prototypes for toys, household appliances, and sports equipment. Gather user feedback on aesthetics, usability, and safety through rapid iteration.

Sustainable Innovation

Leverage eco-friendly materials and additive manufacturing to reduce waste in prototyping. Align with green initiatives while maintaining performance and quality.

Types of Rapid Prototyping

Rapid prototyping (RP) has revolutionized product development by enabling designers and engineers to quickly create physical models of their ideas. This iterative process accelerates innovation, reduces costs, and minimizes risks. Below, we explore the most common types of rapid prototyping technologies, their applications, and their advantages.

1. Stereolithography (SLA)

How It Works: SLA uses a UV laser to cure liquid resin layer by layer, solidifying it into a 3D object.

Applications: Ideal for detailed, high-resolution models, jewelry design, dental prosthetics, and microfluidics.

Advantages:

- Smooth surface finish.

- High accuracy for intricate geometries.

- Fast prototyping for visual and functional testing.

2. Fused Deposition Modeling (FDM)

How It Works: FDM extrudes thermoplastic filaments (e.g., PLA, ABS) through a heated nozzle, depositing material layer by layer.

Applications: Affordable prototyping for consumer goods, automotive parts, and educational projects.

Advantages:

- Cost-effective and user-friendly.

- Wide range of materials available.

- Suitable for rugged, functional prototypes.

3. Selective Laser Sintering (SLS)

How It Works: SLS fuses powdered materials (nylon, metal, or glass) using a high-power laser, building parts layer by layer.

Applications: Industrial design, aerospace components, and custom manufacturing.

Advantages:

- No need for support structures (unfused powder acts as support).

- Durable, functional prototypes.

- Ideal for complex, lightweight designs.

4. Multi-Jet Fusion (MJF)

How It Works: MJF uses inkjet arrays to apply fusing and detailing agents to a powder bed, followed by infrared heating to solidify the material.

Applications: High-volume production of end-use parts, automotive, and healthcare.

Advantages:

- Faster build speeds than SLS.

- Excellent mechanical properties.

- Cost-effective for medium-to-large batches.

5. CNC Machining

How It Works: Computer Numerical Control (CNC) machines subtractively carve prototypes from solid blocks of material (metal, plastic, wood).

Applications: Precision parts, tooling, and low-volume production.

Advantages:

- High accuracy and surface finish.

- Works with a wide range of materials.

- Ideal for durable, production-ready prototypes.

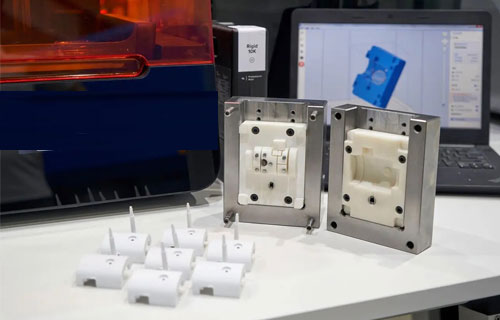

6. Vacuum Casting

How It Works: A silicone mold is created from a master pattern (often 3D-printed), then filled with polyurethane resin under vacuum to produce copies.

Applications: Small-batch production, consumer electronics, and medical devices.

Advantages:

- Low-cost tooling.

- Flexible material options (rubber, transparent, or high-temperature resins).

- Fast turnaround for 20–50 units.

7. Laminated Object Manufacturing (LOM)

How It Works: LOM cuts and bonds sheets of material (paper, plastic, or metal) using a laser and adhesive, then stacks them into a 3D object.

Applications: Architectural models, large-scale prototypes, and educational tools.

Advantages:

- Fast and cost-effective for non-functional prototypes.

- No post-curing required.

- Suitable for large, lightweight parts.

8. Binder Jetting

How It Works: A liquid binder is selectively deposited onto a powder bed, bonding particles together layer by layer.

Applications: Full-color prototypes (e.g., architectural models), sand casting molds, and metal parts (post-sintered).

Advantages:

- Supports multi-material and full-color printing.

- Scalable for large builds.

- No thermal stress on materials.

3D Printing for Rapid Prototyping

In today’s fast-paced product development landscape, time-to-market is everything. Yigu Technology empowers businesses to transform ideas into tangible prototypes faster than ever with cutting-edge 3D printing solutions tailored for rapid prototyping.

Our advanced 3D printing technology enables designers, engineers, and innovators to iterate quickly, test concepts, and refine designs with precision—all while slashing lead times and reducing costs. Whether you’re developing consumer electronics, automotive components, medical devices, or consumer goods, Yigu’s 3D printing services deliver:

- 🛠️Speed: Produce complex prototypes in hours, not weeks, enabling faster decision-making and shorter development cycles.

- 🛠️Precision: High-resolution prints with tight tolerances ensure your prototypes mirror final product specifications.

- 🛠️Material Flexibility: Choose from a wide range of engineering-grade materials, including durable plastics, composites, and flexible filaments, to match your application’s requirements.

- 🛠️Cost Efficiency: Eliminate expensive tooling and minimize material waste, making prototyping accessible for startups and enterprises alike.

CNC Machining for Rapid Prototyping

In a world where innovation thrives on agility, Yigu Technology delivers unmatched CNC machining solutions for rapid prototyping, enabling businesses to bridge the gap between design and production faster than ever. Our advanced CNC (Computer Numerical Control) machining services combine precision engineering with rapid turnaround times, empowering industries—from automotive and aerospace to consumer electronics and medical devices—to iterate, test, and perfect prototypes with confidence.

Why Choose Yigu Technology for CNC Prototyping?

- 📐Lightning-Fast Turnaround: Produce high-fidelity prototypes in days, not weeks, with our streamlined workflow and state-of-the-art CNC milling and turning centers.

- 📐Uncompromising Precision: Achieve tight tolerances (±0.005mm) and intricate geometries, ensuring your prototypes mirror final production quality.

- 📐Material Versatility: Work with a vast array of materials, including metals (aluminum, steel, titanium), engineering plastics, and composites, to match your prototype’s functional requirements.

- 📐Scalability: From single prototypes to low-volume production runs, our flexible CNC services adapt to your project’s needs without compromising speed or quality.

- 📐Expert Guidance: Our seasoned engineers collaborate with you to optimize designs for machinability, reducing costs and accelerating timelines.

Sheet Metal Fabrication for Rapid Prototyping

In industries where durability, functionality, and speed are paramount, Yigu Technology delivers sheet metal fabrication services tailored for rapid prototyping, enabling businesses to transform concepts into robust, production-ready prototypes in record time. From electronics enclosures and automotive components to industrial machinery and custom brackets, our advanced sheet metal solutions combine precision, efficiency, and material versatility to keep your innovation pipeline flowing.

Why Yigu Technology Stands Out for Sheet Metal Prototyping:

- 🏭Lightning-Quick Prototyping: Leverage our agile workflow and state-of-the-art equipment to produce sheet metal prototypes in days, not weeks—reducing time-to-market and accelerating iterations.

- 🏭Precision Engineering: Achieve flawless results with laser cutting, CNC punching, bending, and welding processes that ensure tight tolerances and seamless finishes, even for complex designs.

- 🏭Material Flexibility: Choose from a wide range of metals, including aluminum, stainless steel, mild steel, and copper, to match your prototype’s strength, weight, and aesthetic requirements.

- 🏭Cost-Effective Iterations: Test designs with low-cost prototypes before committing to full production, minimizing risks and optimizing performance.

- 🏭End-to-End Support: Our experienced team guides you through material selection, design optimization, and finishing options (powder coating, anodizing, plating) to ensure your prototypes meet industry standards.

Comparing Prototyping Processes

Choosing the right prototyping process is critical to balancing speed, cost, precision, and material suitability. Whether you’re validating a design, testing functionality, or securing investor buy-in, each prototyping method offers unique advantages. Below, we compare three leading techniques—3D Printing, CNC Machining, and Sheet Metal Fabrication—to help you decide which aligns best with your project goals.

Prototyping Process Comparison Table

| Feature | 3D Printing | CNC Machining | Sheet Metal Fabrication |

|---|---|---|---|

| Speed | Fast (hours–days for simple parts) | Moderate (days for complex parts) | Moderate–Fast (days for standard parts) |

| Cost for Prototypes | Low (no tooling; ideal for iterations) | Moderate (material/tooling costs) | Moderate (material-dependent) |

| Material Options | Wide (plastics, composites, metals) | Limited to solid blocks (metals, plastics) | Metals (aluminum, steel, etc.) |

| Precision & Tolerances | High (±0.1mm typical; varies by tech) | Very High (±0.005mm–0.01mm) | High (±0.1mm–0.5mm, depending on process) |

| Best For | Complex geometries, organic shapes | Tight-tolerance parts, functional testing | Durable enclosures, structural components |

| Scalability | Low-volume runs (1–100 units) | Low-to-mid volume (1–1,000 units) | Mid-to-high volume (10–10,000+ units) |

| Surface Finish | Variable (rough to polished) | Smooth (can be polished/anodized) | Textured/smooth (post-processing needed) |

| Lead Time for Changes | Instant (reprint designs) | Moderate (reprogram CNC tools) | Slower (redesign tooling/fixtures) |

Choosing Rapid Prototyping Process

In today’s fast-paced product development landscape, selecting the optimal rapid prototyping process can be the difference between a breakthrough innovation and a missed opportunity. With a myriad of technologies available—from 3D printing and CNC machining to vacuum casting and injection molding—engineers and designers must weigh factors like speed, cost, material properties, and design complexity to align with project goals.

Key Considerations for Process Selection:

- Speed vs. Precision: While additive manufacturing (e.g., SLA, SLS) excels in rapid iteration and intricate geometries, subtractive methods like CNC machining offer superior surface finishes and dimensional accuracy for functional prototypes.

- Material Requirements: Does your prototype need to mimic end-use properties? Processes like FDM 3D printing suit basic visual models, whereas polyjet or metal sintering cater to high-performance, durable parts.

- Volume & Scalability: For low-volume runs, 3D printing or vacuum casting may suffice. For high-fidelity, scalable prototypes, consider hybrid approaches combining 3D-printed masters with silicone molds.

- Cost Efficiency: Balance upfront tooling costs (e.g., injection molding) with per-unit expenses. Rapid prototyping thrives on minimizing waste—opt for processes that allow quick design adjustments without retooling.

Rapid Prototyping Use Cases

Rapid prototyping has revolutionized product development by enabling teams to transform ideas into tangible models faster than ever before. Whether you are in tech, manufacturing, healthcare, or consumer goods, this agile methodology bridges the gap between concept and reality, reducing risks and speeding up time-to-market. Here is how industries leverage rapid prototyping to drive success:

Consumer Electronics & Wearables

Companies like examples Apple and Samsung use rapid prototyping to test device ergonomics, button layouts, and display functionality before mass production. Iterative 3D-printed models help refine user experience and address design flaws early.

Automotive & Aerospace Engineering

Engineers create lightweight, high-strength components for vehicles and aircraft using additive manufacturing. Rapid prototypes allow for crash-testing simulations, aerodynamic adjustments, and fuel-efficiency optimizations without costly tooling delays.

Medical Devices & Prosthetics

Custom prosthetics, surgical tools, and implants are personalized using rapid prototyping. For instance, 3D-printed orthopedic models help surgeons plan complex procedures, while biocompatible materials accelerate patient-specific solutions.

Retail & Fashion

Brands like Nike and Adidas prototype shoe designs with 3D printing to test comfort, grip, and aesthetics. Rapid iteration ensures products meet consumer trends while minimizing waste from traditional sampling processes.

Architecture & Construction

Architects use 3D-printed scale models to visualize structures, test lighting, and refine spatial layouts. Contractors prototype modular building components for faster assembly and cost-effective customization.

Robotics & IoT

Startups build functional prototypes of drones, robots, and smart devices to validate mechanics, sensor integration, and user interfaces. Rapid prototyping shortens feedback loops, enabling faster pivots based on real-world testing.

What materials are used in rapid prototyping?

Rapid prototyping technologies leverage a diverse range of materials to balance functionality, cost, and manufacturability, enabling designers and engineers to iterate quickly while testing critical performance attributes. The choice of material depends on the prototyping process (e.g., additive, subtractive, or formative) and the intended application of the prototype. Below is a breakdown of key material categories and their technical advantages:

1. Thermoplastics

- Applications: Ideal for functional testing, form-fit-validation, and low-volume production.

- Common Types:

- ABS (Acrylonitrile Butadiene Styrene): Offers high impact resistance and dimensional stability; widely used in FDM 3D printing for consumer goods and automotive prototypes.

- PLA (Polylactic Acid): A biodegradable, eco-friendly option with good printability, though lower heat resistance than ABS; suitable for conceptual models and non-functional parts.

- Nylon (PA): Known for toughness and flexibility; used in SLS (Selective Laser Sintering) for durable, lightweight prototypes requiring mechanical strength.

- PETG (Polyethylene Terephthalate Glycol): Combines transparency, chemical resistance, and ease of printing; favored for medical devices and packaging prototypes.

2. Photopolymers (Resins)

- Applications: High-detail visual models, medical models, and masters for casting.

- Common Types:

- Standard Resins: Provide smooth surface finishes and fine feature resolution; used in SLA (Stereolithography) and DLP (Digital Light Processing) for architectural models and jewelry.

- Engineering Resins: Mimic properties like ABS, PP, or rubber (e.g., Formlabs’ Tough or Flexible Resins); suitable for snap-fit assemblies and ergonomic testing.

- Biocompatible Resins: Certified for medical use (e.g., dental aligners, surgical guides); require post-curing and sterilization compatibility.

3. Metals

- Applications: Aerospace, automotive, and high-performance industrial components.

- Common Types:

- Stainless Steel (316L/17-4 PH): Used in DMLS (Direct Metal Laser Sintering) for corrosion-resistant, load-bearing parts.

- Titanium Alloys (Ti6Al4V): Offers exceptional strength-to-weight ratio; critical for aerospace and medical implants.

- Aluminum (AlSi10Mg): Lightweight with good thermal conductivity; ideal for heat exchangers and automotive prototypes.

4. Composites & Hybrids

- Applications: Enhanced mechanical properties for specialized use cases.

- Examples:

- Carbon Fiber-Reinforced Plastics (CFRP): Integrated into FDM or SLS processes for stiffness and lightweight structures (e.g., drone frames, sporting goods).

- Metal-Matrix Composites (MMCs): Combine metals with ceramics or fibers for high-temperature applications (e.g., turbine blades).

5. Elastomers & Rubbers

- Applications: Seals, gaskets, and flexible consumer products.

- Technologies:

- TPU (Thermoplastic Polyurethane): Printable via FDM for shock-absorbing prototypes (e.g., phone cases, footwear).

- Silicone Rubbers: Used in casting processes (e.g., vacuum casting) to replicate soft-touch finishes and medical-grade flexibility.

6. Ceramics

- Applications: High-temperature, electrically insulating, or biocompatible components.

- Processes: Binder jetting or stereolithography with ceramic-loaded resins, followed by sintering to achieve density and strength.

Material Selection Criteria

- Mechanical Requirements: Tensile strength, elongation, fatigue resistance.

- Thermal Properties: Heat deflection temperature (HDT), thermal conductivity.

- Chemical Resistance: Compatibility with solvents, fuels, or bodily fluids.

- Surface Finish & Aesthetics: Gloss, texture, and post-processing potential (e.g., painting, plating).

- Cost & Availability: Balancing material expense with prototyping budget and lead times.

Advantages & Disadvantages of Rapid Prototyping

Rapid prototyping benefits has revolutionized product development by enabling faster iteration, cost efficiency, and enhanced creativity. One of benefits its key advantages lies in accelerated time-to-market—designers can quickly transform concepts into tangible models, allowing for early testing and validation. This reduces the risk of costly errors later in production. Additionally, rapid prototyping fosters collaboration and communication among stakeholders, as physical prototypes bridge the gap between technical jargon and visual understanding. Its cost-effectiveness in the early stages is another boon, as it minimizes material waste and tooling expenses compared to traditional manufacturing. Moreover, the flexibility to iterate designs encourages innovation, empowering teams to refine products based on real-world feedback.

However, rapid prototyping is not without drawbacks. Material limitations often restrict prototypes to simplified versions of the final product, potentially overlooking critical performance factors like durability or heat resistance. The high initial costs of advanced 3D printers or CNC machines can also be prohibitive for small businesses or startups. Additionally, while rapid prototyping speeds up design phases, post-processing requirements (e.g., sanding, painting) may add unexpected time and labor. Finally, over-reliance on prototypes might lead to shortcuts in rigorous testing, compromising quality if teams prioritize speed over thorough validation.

Rapid Prototyping vs. Traditional Prototyping

The debate between rapid prototyping and traditional prototyping hinges on speed, cost, and the level of detail required to validate a product. Rapid prototyping excels in accelerating innovation by leveraging technologies like 3D printing, CNC machining, or laser cutting to produce physical models in hours or days. This method is ideal for early-stage design exploration, allowing teams to test multiple iterations quickly, gather feedback, and refine concepts before committing to large-scale production. Its agility is unmatched for brainstorming, user testing, or pitching ideas to stakeholders.

In contrast, traditional prototyping—often involving manual crafting, injection molding, or custom tooling—prioritizes precision and durability. While slower and more expensive upfront, it replicates the final product’s materials, mechanics, and aesthetics more faithfully. This approach is critical for validating functional performance, regulatory compliance, or user experience under real-world conditions. Traditional methods also scale better for high-fidelity prototypes destined for market testing or investor demos.

Rapid Prototyping Tools and Methods

Rapid prototyping has transformed product development by enabling designers and engineers to transform ideas into tangible models with unprecedented speed and flexibility. A diverse array of tools and methods empowers teams to iterate efficiently, test assumptions, and refine designs before committing to full-scale production.

At the forefront are additive manufacturing technologies, such as 3D printing (FDM, SLA, SLS), which allow for complex geometries and quick material testing. These methods excel in producing low-fidelity prototypes for form validation, ergonomic studies, or early user feedback. For higher precision and durability, subtractive manufacturing—like CNC machining—offers tight tolerances and a wider range of materials, making it ideal for functional prototypes requiring mechanical testing.

Complementary tools like laser cutters and vinyl cutters provide rapid fabrication of 2D or simple 3D structures, perfect for packaging mockups, electronics enclosures, or quick UI/UX prototypes. Meanwhile, vacuum forming and thermoforming enable rapid replication of curved or organic shapes, bridging the gap between digital designs and physical reality.

Software plays an equally critical role. CAD (Computer-Aided Design) tools (e.g., SolidWorks, Fusion 360, Rhino) streamline 3D modeling, while simulation software (ANSYS, KeyShot) predicts performance, reducing the need for physical iterations. Collaboration platforms like Figma or Adobe XD further enhance workflows by allowing real-time design adjustments and stakeholder feedback.

The choice of method depends on project goals: 3D printing for speed and complexity, CNC for precision, or laser cutting for simplicity. Hybrid approaches—combining multiple tools—often yield the best results, balancing agility with functionality. By mastering these rapid prototyping tools and methods, teams can unlock creativity, minimize risks, and bring products to market faster than ever before.

FAQs List of Rapid Prototyping Services

How Much Does Rapid Prototyping Cost?

Costs vary based on materials, complexity, volume, and method (e.g., 3D printing, CNC). Small projects can start at a few hundred dollars, while complex, high-volume prototypes may cost thousands.

How to Reduce the Cost of Rapid Prototyping?

Optimize designs for simplicity, use affordable materials, choose cost-effective methods (e.g., FDM 3D printing), and negotiate bulk discounts with vendors.

Why is Rapid Prototyping Important in Manufacturing?

It accelerates development, reduces errors, enables iterative testing, and improves collaboration, ensuring products meet market needs before mass production.

What are the Main Techniques Used in Rapid Prototyping?

Common techniques include 3D printing (SLA, SLS, FDM), CNC machining, vacuum casting, injection molding (low-volume), and sheet metal fabrication.

What is the Role of Software in Rapid Prototyping?

Software (CAD, simulation, slicing) designs models jobs, tests functionality, and prepares files for manufacturing, streamlining the prototyping process.

What are the Costs Associated with Rapid Prototyping?

Expenses include materials, labor, machine usage, post-processing (e.g., finishing), and software licenses. Hidden costs may involve design revisions or shipping.

What are the Common Mistakes to Avoid in Rapid Prototyping?

Avoid rushing designs, ignoring material limits, skipping testing, or neglecting stakeholder feedback. Validate early and iterate to prevent costly reworks.

What are the most common rapid prototyping techniques?

FDM, SLA, SLS (3D printing), CNC machining, and vacuum casting are standard PPT due to their speed, precision, and adaptability.

Rapid Prototyping in Three Easy Steps?

- Design: Create a 3D model in CAD.

- Prototype: Fabricate using 3D printing, CNC, etc.

- Test & Iterate: Evaluate, gather feedback, and refine the design.