Flexible FDM 3D Printing Service

Makes FDM 3D Printing Service the Ideal Choice for Your Project

At Yigu technology, we combine technical expertise with state-of-the-art equipment to deliver FDM 3D printing service that meets your needs. Whether you’re looking to prototype a new product, produce custom parts, or bring an idea to life, we offer:

- A wide range of FDM 3D printing materials to match your project’s requirements.

- Fast turnaround times — most prototypes are ready within 24–48 hours.

- Competitive pricing with transparent quotes based on your design.

- Expert design support to optimize your models for FDM printing.

Don’t let traditional manufacturing hold you back. Embrace the flexibility, speed, and cost-effectiveness of FDM 3D printing service and turn your ideas into reality. Contact us today to get started.

What is FDM 3D Printing Service?

At its core, FDM 3D printing service (Fused Deposition Modeling) is a additive manufacturing process that builds objects layer by layer using thermoplastic materials. Unlike traditional subtractive manufacturing, which cuts away material from a solid block, FDM adds material precisely where it’s needed—reducing waste and enabling complex geometries that would be impossible with CNC machining or injection molding.

How FDM 3D printing service works is surprisingly intuitive: A thermoplastic filament (like PLA or ABS) is fed through a heated nozzle, melted, and deposited onto a build platform. The nozzle moves in precise X, Y, and Z axes, laying down layers as thin as 0.1mm to form the final object. This layer-by-layer approach makes FDM ideal for everything from quick prototypes to functional end-use parts.

The FDM 3D Printing Process: From Design to Finished Part

Understanding the process of FDM 3D printing is key to leveraging its full potential. Here’s a step-by-step breakdown of the typical workflow:

- Design Creation: Start with a 3D model using CAD software (such as AutoCAD, Fusion 360, or SolidWorks). This design is then exported as an STL file—a standard format for 3D printing that represents the object’s surface geometry.

- Print Preparation: The sliced file is transferred to the FDM 3D printer via USB, SD card, or Wi-Fi. The printer heats the nozzle (typically between 180°C–260°C, depending on the material) and the build platform.

- Slicing: The STL file is loaded into slicing software (e.g., Cura, Simplify3D), which converts the 3D model into thousands of 2D layers. During this step, you can adjust parameters like layer height, infill density, and print speed.

- Layer Deposition: The printer begins depositing melted filament, starting with the first layer. Each subsequent layer bonds to the one below, gradually building the object from the bottom up.

- Post-Processing: Once printing is complete, the part is removed from the build platform. Depending on the application, post-processing may include removing support structures, sanding for a smoother finish, or painting.

This FDM 3D printing workflow is highly automated, reducing the need for manual intervention and minimizing errors. Most small to medium-sized parts can be printed in 4–24 hours, a fraction of the time required for traditional manufacturing methods.

Material Options: Choosing the Right Filament for Your Project

One of the greatest strengths of FDM 3D printing is its versatility in materials. Here’s a detailed comparison of the most popular options:

| Material | Temperature Resistance | Impact Strength | Flexibility | Cost (per kg) | Best For |

| PLA | Up to 60°C | Low | Rigid | 20–30 | Prototyping, decorative parts, educational models |

| ABS | Up to 90°C | High | Moderate | 25–40 | Functional parts, toys, automotive components |

| PETG | Up to 80°C | Very High | Semi-rigid | 30–50 | Food-safe containers, mechanical parts, outdoor use |

| TPU | Up to 80°C | Excellent | Highly flexible | 40–70 | Gaskets, phone cases, wearable devices |

PLA for FDM 3D printing is the most common choice for beginners due to its ease of use and low warping. Made from renewable resources like cornstarch, it’s also more environmentally friendly. However, its low temperature resistance makes it unsuitable for parts exposed to heat.

ABS for FDM 3D printing offers better mechanical properties but requires a heated build platform to prevent warping. It’s a favorite in industrial settings for functional prototypes and end-use parts.

TPU for FDM 3D printing stands out for its elasticity, making it ideal for any application requiring flexibility or shock absorption. Meanwhile, PETG for FDM 3D printing strikes a balance between PLA and ABS, offering strength, durability, and ease of printing.

When selecting FDM 3D printing materials, consider factors like mechanical stress, temperature exposure, chemical resistance, and cost. Our team can help you choose the optimal material based on your specific needs.

Applications: Where FDM 3D Printing Makes a Difference

FDM 3D printing service has revolutionized countless industries by offering fast, affordable, and customizable solutions. Here are some key applications:

- Prototyping: Engineers and designers rely on FDM to create functional prototypes in days, not weeks. This accelerates the product development cycle, allowing for rapid iteration and testing. A recent study found that companies using FDM for prototyping reduced their time-to-market by an average of 40%.

- Manufacturing: Small-batch production runs are where FDM truly shines. Unlike injection molding, which requires expensive tooling, FDM allows for cost-effective production of 1–1000 parts. Automotive manufacturers use FDM to produce custom jigs and fixtures, reducing assembly line downtime by up to 30%.

- Education: Schools and universities use FDM printers to teach design, engineering, and manufacturing concepts. Students can turn their ideas into tangible objects, enhancing learning through hands-on experience.

- Healthcare: From anatomical models for surgical planning to custom orthotics, FDM is making waves in healthcare. A study published in the Journal of Medical Engineering found that surgeons using 3D-printed models reduced operation times by 28% on average.

- Architecture: Architects create detailed scale models using FDM, allowing clients to visualize projects before construction begins. This reduces misunderstandings and changes later in the building process, saving time and money.

Advantages: Why Choose FDM 3D Printing Service?

The benefits of FDM 3D printing are hard to ignore, especially when compared to traditional manufacturing methods:

- Cost-effectiveness: FDM eliminates the need for expensive tooling and molds, making it ideal for small production runs. For parts under 100 units, FDM is typically 50–80% cheaper than injection molding.

- Speed: From design to finished part, FDM can produce objects in a matter of hours. This is crucial for time-sensitive projects and rapid prototyping.

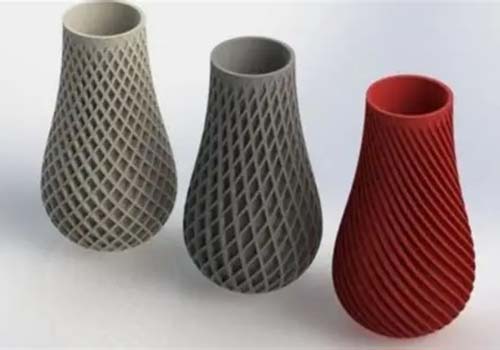

- Design freedom: FDM allows for complex geometries, including internal structures and overhangs, that would be impossible with CNC machining or injection molding.

- Accessibility: FDM printers are more affordable than other 3D printing technologies, making the service accessible to small businesses, startups, and educational institutions.

- Sustainability: By using only the material needed for the part, FDM reduces waste by up to 90% compared to subtractive manufacturing. Many FDM materials are also recyclable.

Customization and Design: Tailored Solutions for Your Unique Needs

Customization in FDM 3D printing service is where the technology truly shines. Whether you need a one-of-a-kind prototype or a batch of custom parts, FDM allows for unlimited design possibilities.

Our team of engineers specializes in design for FDM 3D printing, helping you optimize your models for the printing process. We can provide guidance on:

- Wall thickness: Ensuring parts are strong enough without using excess material.

- Overhangs: Designing features that can be printed without supports, reducing post-processing time.

- Infill: Balancing strength and weight by adjusting the internal structure.

- Tolerances: Setting appropriate clearances for moving parts or assemblies.

We accept CAD design for FDM 3D printing in most major formats, including STL, STEP, and IGES. If you don’t have a 3D model, our design team can create one for you based on your specifications. We also offer file repair services to ensure your STL files for FDM 3D printing are print-ready.

Quality and Precision: Meeting Your Exacting Standards

When it comes to quality of FDM 3D printing service, we never compromise. Our printers achieve a precision in FDM 3D printing of ±0.1mm, with layer heights as small as 0.05mm for exceptional detail.

FDM 3D printing accuracy is maintained through rigorous calibration and regular maintenance of our equipment. We use high-quality filaments from trusted manufacturers to ensure consistent results, batch after batch.

The surface finish of FDM 3D printing can be customized based on your needs. For functional parts where surface smoothness isn’t critical, a standard finish is sufficient. For parts requiring a polished look, we offer post-processing services that can achieve a surface roughness (Ra) as low as 1.6μm.

Tolerance in FDM 3D printing is carefully managed through our slicing software and printer settings. We work with you to determine the appropriate tolerances for your application, ensuring parts fit together perfectly when needed.

Our quality control in FDM 3D printing process includes pre-print design checks, in-process monitoring, and post-print inspections. Every part is measured against your specifications before being shipped, guaranteeing that you receive only the highest quality components.

Cost and Pricing: Transparent Pricing for Every Project

Understanding the cost of FDM 3D printing service is essential for budgeting your project. Unlike traditional manufacturing, FDM pricing is based on several key factors:

- Material usage: The amount of filament required, measured in grams or kilograms.

- Print time: The duration of the print job, typically calculated in hours.

- Post-processing: Any additional work needed after printing, such as support removal, sanding, or painting.

- Design complexity: Highly detailed parts or those with complex geometries may require more setup time and expertise.

On average, FDM 3D printing pricing per hour ranges from 5to20, depending on the printer’s size and capabilities. Small parts (under 100g) can cost as little as 10–30, while larger, more complex parts may range from 50to500. For comparison, injection molding tooling alone can cost $10,000 or more—making FDM the clear choice for small-batch production. We offer both FDM 3D printing pricing per project and volume discounts for larger orders. Our transparent pricing model ensures you know exactly what to expect, with no hidden fees or surprises.

Equipment and Tools: State-of-the-Art Printers for Superior Results

We invest in the best FDM 3D printing equipment to deliver consistent, high-quality results. Our fleet includes printers from leading FDM 3D printer brands such as Ultimaker, Prusa, and MakerBot, with build volumes ranging from 150x150x150mm to 400x400x400mm.

Each FDM 3D printer models in our workshop is regularly maintained and calibrated to ensure optimal performance. We use high-quality FDM 3D printing tools and accessories, including heated build platforms, enclosure systems for temperature-sensitive materials, and advanced slicing software.

Our team of certified technicians has extensive experience with all aspects of FDM printing, from setup and calibration to troubleshooting and maintenance. This expertise ensures that every print job meets our strict quality standards.

FDM 3D Printing FAQ

How long does it take to print an object using FDM 3D printing?

The printing time depends on several factors, including the size and complexity of the object, the layer height, and the print speed settings. A small object with a simple design might take 30 minutes to an hour, while a larger or more intricate object could take several hours or even days.

What are the limitations of FDM 3D printing?

The main limitations of FDM 3D printing include lower resolution compared to other 3D printing technologies like SLA or SLS. It may also have issues with surface finish and mechanical strength, especially for complex or thin-walled structures. Additionally, the printing speed can be relatively slow for large objects.

What is the typical resolution of FDM 3D printed objects?

The resolution of FDM 3D printed objects is usually measured in layer height. Typical layer heights range from 0.1 mm to 0.3 mm. Higher resolution (smaller layer height) results in smoother surfaces but longer print times.

How do I prepare a digital model for FDM 3D printing?

To prepare a digital model for FDM 3D printing, you need to create or obtain a 3D model file (usually in STL or OBJ format). Then, use slicing software (such as Cura or PrusaSlicer) to convert the model into G-code, which is the language understood by the 3D printer. The software will also allow you to adjust print settings like layer height, infill density, and print speed.

What maintenance is required for an FDM 3D printer?

Regular maintenance for an FDM 3D printer includes cleaning the print bed, checking and cleaning the nozzle, ensuring the extruder is properly calibrated, and keeping the printer firmware up to date. It’s also important to store filament in a dry place to prevent moisture absorption, which can affect print quality.

Can I use FDM 3D printing for commercial purposes?

Yes, FDM 3D printing can be used for commercial purposes, especially for prototyping, small-scale production, and custom manufacturing. However, for high-volume production or applications requiring very high precision, other 3D printing technologies or traditional manufacturing methods might be more suitable.