Introduction to Rapid Prototyping

Rapid prototyping, also known as rapid application development (RAD), has revolutionized the field of engineering design. This method allows designers and engineers to quickly create and test prototypes of their designs, significantly influencing how products are developed. The integration of rapid prototyping techniques speeds up the product development cycle, reduces costs, and enables iterative improvements based on immediate feedback. In this article, we will explore how rapid prototyping impacts engineering design, its benefits, tools, and technologies, and its role in modern engineering practices.

Definition and History

What is Rapid Prototyping?

Rapid prototyping is a process used to quickly fabricate scale models of physical parts using three-dimensional computer-aided design (CAD) data. It involves creating a prototype that can be tested and validated before moving on to full-scale production. This method contrasts with traditional prototyping methods that often involve more time-consuming and expensive processes.

Historical Background

The concept of rapid prototyping emerged in the late 20th century, driven by advancements in computer technology and materials science. One of the earliest forms of rapid prototyping was stereolithography, developed by Charles Hull in the 1980s. Since then, various other technologies such as Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and 3D printing have been developed, further advancing the capabilities of rapid prototyping.

Benefits of Rapid Prototyping

Speed and Efficiency

One of the most significant benefits of rapid prototyping is the acceleration of the product development cycle. By allowing quick creation and testing of prototypes, engineers can identify issues early and make necessary adjustments without delay. This speed and efficiency enable faster time-to-market, which is critical in competitive industries.

Cost-Effectiveness

Rapid prototyping reduces the overall cost of product development. Traditionally, creating multiple prototypes was expensive and time-consuming. Rapid prototyping minimizes these costs by using less material and reducing labor expenses associated with manual prototyping methods.

Iterative Improvements

With rapid prototyping, engineers can make iterative improvements based on immediate feedback. Each prototype provides valuable insights that can be used to refine the design, leading to better final products. This iterative process ensures continuous improvement and higher-quality outcomes.

Integration in Engineering Design

Role in the Design Process

Rapid prototyping plays a crucial role in the design process by providing a tangible model of the design concept. Engineers can physically interact with the prototype, test its functionality, and gather data that informs further design iterations. This hands-on approach enhances understanding and decision-making throughout the design process.

Tools and Technologies

Several tools and technologies are commonly used in rapid prototyping:

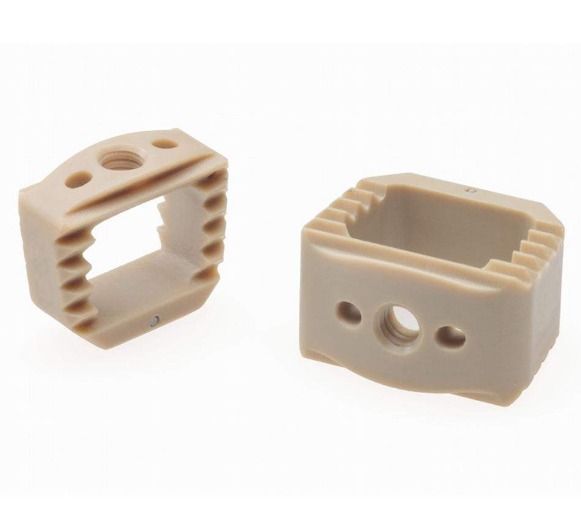

- 3D Printing: Also known as additive manufacturing, 3D printing builds objects layer by layer from digital models.

- CNC Machining: Computer Numerical Control (CNC) machines use automated tools to remove material from a workpiece.

- Laser Cutting: Uses a high-powered laser to cut materials into precise shapes.

- Vacuum Forming: A process where plastic sheets are heated and formed over molds using vacuum pressure.

Each of these technologies offers unique advantages depending on the specific requirements of the project.

Impact on Product Development

Accelerated Development Cycle

Rapid prototyping accelerates the development cycle by enabling engineers to move quickly from concept to prototype and then to the final product. This speed is essential in industries where market demands change rapidly, such as consumer electronics and automotive sectors.

Cost-Effectiveness

By reducing the need for extensive manual labor and minimizing material waste, rapid prototyping is highly cost-effective. Companies can save significant amounts of money that would otherwise be spent on traditional prototyping methods. Additionally, the ability to make iterative changes without starting from scratch further enhances cost savings.

Iterative Improvements

The iterative nature of rapid prototyping allows for continuous improvement of the design. Engineers can test different variations and make real-time adjustments, ensuring that the final product meets all specifications and customer expectations. This flexibility is particularly beneficial in complex projects where multiple factors must be considered.

Case Studies

Success Stories

Case Study 1: Automotive Industry

A leading car manufacturer used rapid prototyping to develop a new line of electric vehicles. By creating multiple prototypes and testing them under various conditions, the company was able to optimize the design for performance and safety. The result was a groundbreaking vehicle that met all regulatory standards and exceeded customer expectations.

Case Study 2: Medical Devices

A medical device company utilized rapid prototyping to develop a new surgical instrument. The ability to quickly create and test prototypes allowed the company to refine the design and ensure it met all safety and usability requirements before going to market. This led to a successful product launch and increased market share.

Challenges and Solutions

Common Challenges

While rapid prototyping offers numerous benefits, there are some challenges that companies may face:

- Material Limitations: Some rapid prototyping methods have limitations on the types of materials that can be used.

- Initial Costs: The initial investment in rapid prototyping equipment and software can be significant.

- Skill Requirements: Operating advanced rapid prototyping equipment requires specialized skills and training.

Solutions

To overcome these challenges, companies can:

- Research Alternative Materials: Investigate alternative materials that are compatible with rapid prototyping technologies.

- Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis to determine the long-term savings and benefits of rapid prototyping.

- Training Programs: Implement training programs to equip staff with the necessary skills to operate rapid prototyping equipment effectively.

Conclusion

Recap of Rapid Prototyping's Influence

Rapid prototyping has had a profound impact on the field of engineering design. By accelerating the product development cycle, reducing costs, and enabling iterative improvements, it has transformed how engineers approach design. The integration of advanced tools and technologies has made rapid prototyping an indispensable part of modern engineering practices.

Importance in Modern Engineering Practices

In today’s fast-paced world, rapid prototyping is essential for staying competitive and meeting market demands. Its ability to quickly adapt to changes and customer needs makes it a valuable asset in any engineering toolkit. As technology continues to advance, the role of rapid prototyping in engineering design is only expected to grow.

FAQs

What is the difference between rapid prototyping and traditional prototyping?

Traditional prototyping typically involves manual methods and longer lead times, whereas rapid prototyping uses automated processes and advanced technologies to create prototypes quickly and efficiently. Rapid prototyping allows for faster iterations and lower costs compared to traditional methods.

How can rapid prototyping benefit small businesses?

Small businesses can benefit from rapid prototyping by reducing development costs and shortening the time to market. It allows them to compete with larger companies by quickly refining their products based on customer feedback and making cost-effective improvements.

Are there any limitations to rapid prototyping?

While rapid prototyping offers many advantages, there are some limitations such as material constraints and initial investment costs. However, these limitations can often be mitigated through research, alternative materials, and conducting a detailed cost-benefit analysis.

Mold7 provides a comprehensive understanding of how rapid prototyping impacts engineering design, its key benefits, tools, technologies, and practical applications.