Prototyping and Manufacturing Application in 3C Digital parts Industries

Accelerate Your 3C Product Development with Yigu Manufacturing Solutions. Streamline your 3C product lifecycle—from concept to market—with Yigu advanced rapid prototyping and mass production services.

Key Benefits:

✔ ✅Rapid Prototyping: 3D printing, CNC machining, and SLA for fast design validation.

✔ ✅Mass Production: High-volume injection molding and automated assembly.

✔ ✅Precision & Speed: Tight tolerances (±0.05mm) and 15-30% faster lead times.

✔ ✅Cost Efficiency: Scalable solutions to reduce per-unit costs.

ISO-certified, 10+ years in 3C manufacturing, end-to-end support. Launch smarter, faster.

In the fast-paced world of 3C digital industries, the seamless integration of rapid prototyping and mass production manufacturing is crucial for staying competitive. At Yigu Technology, we have been at the forefront of leveraging these technologies to drive innovation and efficiency in our product development processes.

The Role of Rapid Prototyping in 3C Digital Product Design

Rapid prototyping has revolutionized the way we approach 3C digital product design. With technologies such as 3D printing, additive manufacturing, and laser engraving/cutting, we can create high-precision models and prototypes in a fraction of the time it used to take. This allows us to iterate quickly, test different design concepts, and make necessary adjustments before moving on to mass production. For instance, using stereolithography (SLA) for high-precision 3C models enables us to achieve the exact dimensions and details required for our products, ensuring that the final design meets our stringent quality standards.

Moreover, rapid prototyping software tailored for 3C digital products has been a game-changer. It allows our designers to visualize and simulate the product in a virtual environment, identifying potential issues early in the design phase. This not only saves time but also reduces costs associated with physical prototyping and rework. Virtual prototyping and simulation also enable us to conduct user-centered design testing, ensuring that our products meet the needs and preferences of our target users.

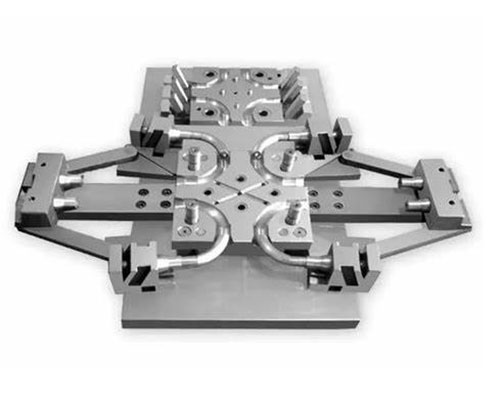

Mass Production Methodologies for 3C Digital Devices

When it comes to mass production, the focus shifts to efficiency, scalability, and cost-effectiveness. High-volume manufacturing of 3C digital devices requires robust production processes and advanced technologies. Automated assembly lines and lean production principles are essential for maintaining high output while minimizing waste and defects. Just-in-time (JIT) production ensures that we have the right components at the right time, reducing inventory costs and improving overall production efficiency.

Supply chain management is another critical aspect of mass production. Efficient supply chain operations ensure a steady flow of raw materials and components, reducing the risk of production delays. Outsourcing strategies for certain manufacturing processes can also be beneficial, allowing us to leverage specialized expertise and reduce operational costs. Continuous improvement cycles are implemented to constantly refine and optimize our production processes, ensuring that we stay ahead of the competition.

Bridging the Gap Between Prototyping and Production

One of the biggest challenges in the 3C digital industries is bridging the gap between rapid prototyping and mass production. At Yigu Technology, we have developed agile manufacturing practices that enable a smooth transition from prototype to mass-produced products. Digital twin technology plays a vital role in this process, allowing us to create virtual replicas of our products and production processes. These digital twins can be used for simulation and optimization, ensuring that the final product meets the same high standards as the prototype.

Rapid iteration cycles are essential for staying competitive in the fast-changing 3C digital market. Our collaborative prototyping and production teams work closely together, sharing data and insights to make informed decisions. Rapid tooling changes and flexible manufacturing systems allow us to quickly adapt to product variations and customer demands. Prototyping serves as a risk reduction tool, allowing us to identify and address potential issues before they become major problems in mass production.

Case Studies of 3C Digital Parts

Case Study 1: Innovative Smartphone Case Design

In one of our recent projects, we were tasked with designing and manufacturing a new smartphone case. Using rapid prototyping technologies, we created multiple iterations of the case design, testing different materials and features. 3D printing allowed us to quickly produce prototypes and make adjustments based on user feedback. Once we had a final design that met our requirements, we transitioned to mass production using high-volume manufacturing techniques.

The automated assembly lines ensured that each case was produced with precision and consistency. Lean production principles helped us minimize waste and reduce production costs. The end result was a high-quality smartphone case that met customer expectations and was delivered on time.

Case Study 2: Next-Generation Tablet Development

Another notable project was the development of a next-generation tablet. The rapid prototyping phase involved using additive manufacturing to create complex internal components and testing various materials for durability and performance. Virtual prototyping and simulation allowed us to optimize the design for user experience and functionality.

During mass production, we implemented just-in-time production processes to ensure that components were available when needed. Continuous improvement cycles were used to refine the production process, resulting in a high-quality tablet that met market demands. The seamless integration of prototyping and production enabled us to bring the product to market faster than our competitors.

Material Advancements for 3C Digital Prototyping and Manufacturing

Material advancements have played a significant role in enhancing both rapid prototyping and mass production in the 3C digital industries. Innovative materials that are lightweight yet durable, conductive, and transparent have opened up new possibilities for product design and functionality. Eco-friendly and biodegradable materials are also gaining importance as we strive to create sustainable products.

Cost-effective material alternatives and recyclable materials are essential for reducing production costs and minimizing environmental impact. Material testing and validation ensure that the chosen materials meet the required performance standards and reliability. Staying ahead of emerging material trends allows us to incorporate the latest advancements into our products, giving us a competitive edge in the market.

Quality Management and Testing in 3C Digital Product Manufacturing

Quality management is a cornerstone of our manufacturing process. Comprehensive quality control processes and statistical process control (SPC) ensure that every product meets our high standards. Rigorous testing methodologies, including non-destructive testing (NDT), are used to verify the integrity of components and the overall performance of the product.

Compliance with international standards is crucial for our products to be accepted in global markets. Dimensional accuracy and tolerance control are maintained throughout the production process to ensure that all parts fit together perfectly. Functional and performance testing, as well as environmental and stress testing, validate the durability and reliability of our 3C digital products. Continuous quality improvement initiatives are implemented to constantly refine our processes and enhance product quality.

Conclusion

The integration of rapid prototyping and mass production manufacturing in the 3C digital industries is a complex yet rewarding endeavor. At Yigu Technology, we have successfully leveraged these technologies to drive innovation, improve efficiency, and deliver high-quality products to our customers. By bridging the gap between prototyping and production, staying ahead of material advancements, and implementing robust quality management processes, we are well-positioned to thrive in the competitive 3C digital market.