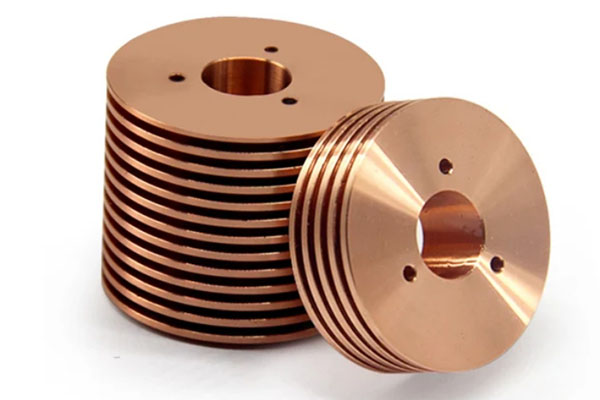

CNC Machining C90300 Bronze: A Comprehensive Engineering Guide

C90300 bronze is a versatile alloy widely used in marine and industrial applications, but machining it requires careful handling of its ductility and unique properties. Its high tin content makes it prone to material adhesion on tools, leading to poor surface finishes and increased tool wear. This guide addresses these challenges, providing practical strategies to […]