SAE 841 bronze stands out as a unique porous, self-lubricating material, but its specialized structure creates distinct machining challenges. Unlike solid bronzes, its interconnected pores and oil-impregnated matrix can lead to tool clogging, uneven material removal, and damage to the lubricating oil reservoir during processing. This guide addresses these pain points, providing actionable strategies to master CNC machining of SAE 841 bronze.

Alloy Identity & Powder-Metallurgy Construction

SAE 841 bronze, often called oil-impregnated bronze, is a powder-metallurgy alloy composed of 87-90 % Cu, 8-10 % Sn, and trace amounts of <1 % C/Fe. Its unique structure is created through powdered-metal sintering, a process that fuses metal particles while leaving 20–25 % interconnected porosity.

This porosity is intentionally preserved to hold lubricant: vacuum impregnation fills the pores with SAE 30 oil at 18–20 % vol, enabling self-lubrication in applications where external lubrication is impractical. The sintering process ensures uniform pore distribution, but this same porosity makes machining tricky—cutting tools must navigate air pockets and oil-filled voids without compromising the material’s functional properties.

| Feature | SAE 841 Specification |

| Copper Content | 87-90 % Cu |

| Tin Content | 8-10 % Sn |

| Porosity | 20–25 % (interconnected) |

| Oil Capacity | 18–20 % vol (SAE 30) |

Mechanical & Physical Properties

SAE 841 bronze balances strength and self-lubrication with mechanical properties tailored for bearing applications. Its UTS (Ultimate Tensile Strength) ranges from 14–26.5 ksi, with yield strength at 11–14 ksi and compressive strength reaching 35 ksi—sufficient for low to moderate loads in bushings and washers.

Hardness measures Rb 30–40 on the Rockwell scale, making it softer than solid bronzes but still machinable with proper tools. Elongation is limited to 1 %, indicating brittleness due to the sintered structure, so machining must avoid excessive stress.

With a density of 6.4–7 g/cm³ (lower than solid bronze’s 8.8 g/cm³) and moderate thermal conductivity, it performs well in 1 800–2 000 °F service range—ideal for high-temperature bearings in automotive and industrial equipment. Its corrosion resistance is comparable to other tin bronzes, though porosity requires care to prevent fluid ingress beyond the oil reservoir.

CNC Machining Strategies for Porous Bronze

Interrupted Cuts and Light Depths

Interrupted cuts are inherent to machining SAE 841 bronze, as tools repeatedly encounter pores. Using light depths of cut (0.1–1 mm) reduces shock loading on tools, preventing chipping—critical for maintaining sharp edges in carbide K20-K30 inserts.

Tool Selection: Carbide and PCD

Carbide K20-K30 inserts are workhorses for roughing, offering durability against the abrasive sintered particles. For finishing, PCD finishing tools deliver smooth surfaces without smearing porous edges, preserving oil-holding capacity.

Rake Angles and Coolant Strategies

High rake angles (10–15°) reduce cutting forces, minimizing distortion in the brittle material. Flood coolant is essential for roughing, flushing debris from pores to prevent clogging. For finishing, MQL (Minimum Quantity Lubrication) preserves the oil fill, avoiding coolant dilution of the lubricant reservoir.

Low Clamping Pressure and Sealed Chip Containment

Low clamping pressure prevents crushing pores in thin-walled parts like thrust washers. Sealed chip containment captures oil-saturated chips, avoiding contamination and ensuring workplace safety.

Tooling & Cutting Parameters

Cutting Speed, Feed, and Tool Coatings

- Cutting speed: 100–250 m/min (slower for porous sections to avoid tool bounce).

- Feed rate: 0.05–0.15 mm/tooth (faster feeds risk burring; slower rates improve surface finish).

- Tooling: Coated micro-grain carbide (AlTiN or TiCN) resists wear from sintered particles. Sharp edges prevent tearing pores, while burr control is critical—deburring must not widen pores.

Tool Wear Monitoring and Coolant Filtration

Tool wear monitoring is vital: dull tools smear material, clogging pores. Replace inserts when flank wear exceeds 0.2 mm. Coolant filtration (10–20 µm) prevents debris from lodging in pores, preserving lubrication capacity.

Surface Finish & Dimensional Control

Ra 0.2–0.8 µm and Tolerances

Achieving Ra 0.2–0.8 µm requires sharp PCD tools and light finishing passes. SAE 841 bronze holds ±0.01 mm tolerance when machined with rigid setups, critical for bearing fits.

Burnish-Free Edges and Inspection

Burnish-free edges prevent pore closure—avoid aggressive deburring. CMM inspection verifies dimensions, while roundness <1 µm ensures proper bearing rotation.

Deburring Without Opening Pores

Deburring must be gentle (e.g., vibratory finishing with ceramic media) to avoid enlarging pores, which would reduce oil retention.

Typical Applications & Industry Segments

Self-Lubricating Components

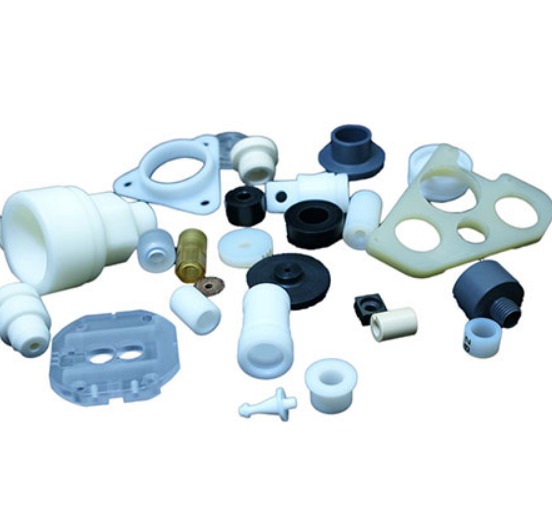

Self-lubricating bushings and sleeve bearings are the primary applications, leveraging SAE 841’s oil-impregnated design for maintenance-free operation in automotive linkage and agricultural pivot points.

Thrust Washers and High-Temp Parts

Thrust washers in industrial machinery rely on its compressive strength, while its high service temperature range suits components in furnaces and exhaust systems.

Food-Grade and Low-Maintenance Uses

Food-grade conveyors use SAE 841 bronze to avoid lubricant contamination, and high-load/low-maintenance mechanisms (e.g., aerospace flap hinges) benefit from its long service life without re-lubrication.

Yigu Technology specializes in machining SAE 841 bronze, understanding the balance between preserving porosity and achieving precision. Our expertise in tool selection, coolant management, and low-stress fixturing ensures parts retain their self-lubricating properties while meeting tight tolerances. Trust us for reliable, oil-impregnated components.

FAQs

- Can SAE 841 bronze be re-oiled after machining?

Yes—post-machining vacuum re-impregnation restores oil lost during cutting, ensuring full lubrication capacity.

- Why avoid high cutting speeds in SAE 841?

High speeds generate heat that can cook the oil in pores, creating carbon deposits that clog lubrication pathways.

- How to check for pore clogging after machining?

Ultrasonic testing or weight measurement before/after oil re-impregnation verifies that pores remain open and functional.