Introduction to China CNC Machining Services

China has become a global leader in CNC (Computer Numerical Control) machining, providing businesses worldwide with precision, efficiency, and cost-effective solutions. The country's CNC machining services are widely regarded for their ability to deliver high-quality, custom-manufactured components that meet the rigorous demands of industries like aerospace, automotive, electronics, and medical devices. This article examines the top China CNC machining services, their advantages, and the industries that benefit most from these services.

An Overview of the Chinese CNC Machining Industry

The Chinese CNC machining industry has expanded significantly over the past few decades. With rapid technological advancements, a highly skilled workforce, and access to cutting-edge machinery, China is now at the forefront of global CNC manufacturing. The industry spans various machining processes, including CNC milling, CNC turning, drilling, and grinding, offering solutions for a wide array of materials, including metals, plastics, and composites.

Chinese CNC manufacturers are well known for their flexibility, enabling them to produce both small batches of custom prototypes and large-scale production runs. This scalability is a key factor in China's appeal as an outsourcing destination for businesses in need of high-precision parts.

Key Advantages of China CNC Machining

1. Cost-Effectiveness and Skilled Workforce

One of the most compelling reasons for outsourcing CNC machining projects to China is cost savings. Labor costs in China are significantly lower than in Western countries, which allows manufacturers to offer competitive pricing without compromising on quality. The Chinese workforce is also highly skilled in CNC machining, ensuring high standards of precision and efficiency in every project.

2. Advanced Technology and Equipment

China is home to some of the world’s most advanced CNC machines, including 3-axis, 4-axis, and 5-axis CNC machines. These machines enable manufacturers to produce complex, high-precision components with ease. Additionally, advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are used to optimize the machining process, improving both the efficiency and accuracy of production.

3. Scalability and Rapid Turnaround Times

China CNC machining services are known for their ability to handle projects of any size. Whether it’s a rapid prototype or a large-scale production run, Chinese manufacturers can quickly scale up operations to meet tight deadlines. This flexibility and speed make China an attractive choice for businesses looking for fast turnaround times and cost-effective manufacturing solutions.

Services Offered by Top China CNC Providers

China’s CNC machining services are incredibly versatile, offering a wide range of options for businesses across various industries.

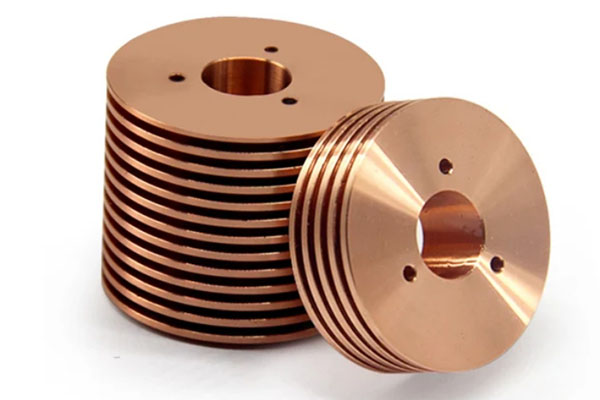

CNC Milling and Turning Services

- CNC Milling involves the use of rotating tools to remove material from a workpiece. This process is ideal for creating complex shapes and precise dimensions.

- CNC Turning uses a rotating workpiece and stationary tools to remove material, primarily used for cylindrical parts. Both services are essential for producing intricate and precise components, ranging from simple mechanical parts to highly complex geometries.

Metal and Plastic CNC Machining

Top Chinese CNC providers offer machining services for a broad range of materials, from aluminum, stainless steel, and titanium to various plastics (like ABS, PVC, and PEEK). This wide material compatibility ensures that manufacturers can meet the demands of industries like aerospace, automotive, medical, and electronics.

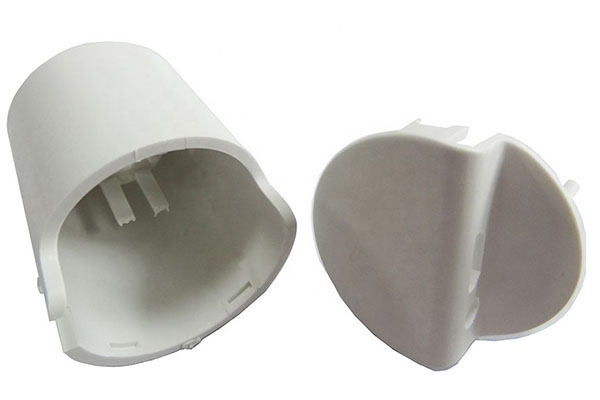

Rapid Prototyping and Custom CNC Manufacturing

China CNC service providers excel at rapid prototyping, which allows businesses to quickly create physical prototypes from digital designs. This process is particularly useful for industries that need to test new designs before moving to full-scale production. Custom CNC manufacturing is also available for one-off or low-volume parts, ensuring that clients get exactly what they need.

Industries Served by China CNC Services

China CNC machining services cater to a variety of industries, each with its specific demands for high precision and quality.

Aerospace

The aerospace industry requires parts that meet the highest levels of precision and reliability. China CNC providers are equipped to produce critical aerospace components, including engine parts, aircraft frames, and landing gear components, with tight tolerances and strict quality controls to meet safety and performance standards.

Automotive

China CNC machining is widely used in the automotive industry to produce high-quality parts such as engine components, transmission parts, and brake components. Chinese manufacturers are also adept at producing specialized parts for electric vehicles (EVs), hybrid cars, and autonomous vehicles.

Electronics

In the electronics industry, CNC machining services are used to produce microcomponents, casings, and printed circuit boards (PCBs) for consumer electronics like smartphones, computers, and wearable devices. These parts often require extremely high precision due to their small size and complex geometries.

Medical Devices

The medical device industry demands precision and cleanliness in its manufacturing processes. China CNC machining services provide the necessary capabilities to produce surgical instruments, implants, and diagnostic equipment with stringent quality control measures to meet regulatory standards, including ISO 13485 certifications.

Selecting the Right China CNC Service Provider

When outsourcing CNC machining projects to China, it’s essential to choose the right provider to ensure success. Here are some factors to consider:

1. Experience and Expertise

Look for a provider with extensive experience in CNC machining and a track record of successful projects in your industry. Providers with experience in your specific sector will better understand your needs and be able to deliver high-quality results.

2. Technology and Equipment

Make sure the provider uses state-of-the-art technology and equipment, including 5-axis CNC machines and advanced CAD/CAM systems, to ensure the highest precision and efficiency.

3. Quality Control Measures

Quality control is essential in CNC machining. Choose a provider with a solid quality management system in place, including inspections, testing, and certifications such as ISO 9001. This ensures your parts meet the highest standards of quality.

4. Material Compatibility

Ensure that the provider can handle the specific materials required for your project. Whether you need metals like titanium and stainless steel or specialized plastics like PEEK, the provider should be capable of machining these materials with high precision.

5. Lead Times and Pricing

Consider the provider’s lead times and pricing structure. Although China offers cost-effective solutions, it’s crucial to ensure that the provider can meet your deadlines without sacrificing quality. Transparent pricing and clear communication are key.

Case Studies of Successful China CNC Projects

Here are a few examples of how China CNC machining services have helped businesses achieve success:

1. High-Precision Aerospace Components

A leading aerospace company needed high-precision components for a new aircraft model. By partnering with a top China CNC provider, they were able to produce critical components with tight tolerances and complex geometries using advanced 5-axis CNC machines. The result was a significant reduction in production costs and faster time-to-market for the new aircraft.

2. Custom Medical Devices

A medical device manufacturer needed a set of custom surgical instruments with intricate designs. By working with a reputable China CNC provider, the company was able to rapidly prototype and refine the designs. The final products met regulatory standards and were delivered on time, all at a fraction of the cost compared to domestic manufacturing.

3. Innovative Automotive Parts

An automotive company needed prototypes for a new engine component design. By partnering with a top China CNC provider, they were able to quickly produce high-quality CNC-milled prototypes. The prototypes were tested, refined, and then used for a larger production run, showcasing the flexibility and capability of Chinese CNC machining services.

Conclusion: The Impact of China CNC Services on Global Manufacturing

China's CNC machining services have become a key driver of innovation and cost-effectiveness in global manufacturing. With advanced technology, a highly skilled workforce, and the ability to scale production rapidly, Chinese CNC providers are helping businesses across industries reduce costs, improve efficiency, and achieve high levels of precision.

Whether you are in aerospace, automotive, electronics, or medical devices, outsourcing your CNC machining needs to China can offer significant benefits in terms of cost savings, quality, and turnaround time. By carefully selecting the right provider and considering factors such as experience, technology, quality control, material compatibility, and pricing, businesses can maximize the potential of China's CNC machining services and stay ahead of the competition in a rapidly evolving global market.