What Are the Best 3D Items to Print for Every Need?

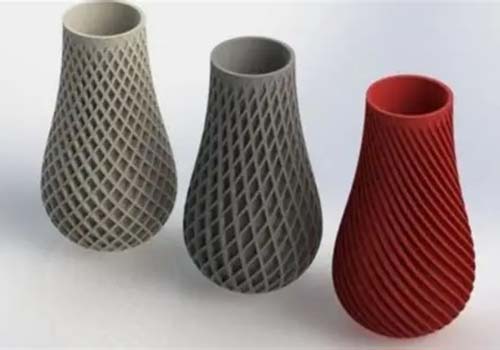

If you’re new to 3D printing or looking for fresh project ideas, the best 3D items to print balance usefulness, printing difficulty, and material availability. Whether you want to fix household problems, organize your space, or make unique gifts, there are options for every skill level—from simple keychains (that take 1–2 hours to print) to […]