If you’ve ever tried to 3D print a large or complex model, you’ve probably run into a common problem: your printer’s build plate is too small. The good news is you don’t need to buy a bigger printer—splitting 3D models for printing lets you break large designs into smaller, printable parts that you can assemble later. This process not only fits models to your printer’s size but also reduces warping, improves layer adhesion, and makes it easier to fix mistakes (no more reprinting the entire model if one section fails). In this guide, we’ll cover everything you need to know to split models correctly, from choosing the right tools to avoiding common pitfalls.

Why Splitting 3D Models for Printing Is Necessary

Before diving into the “how,” let’s clarify why splitting is often a must for 3D printing success. Even high-end consumer 3D printers have limited build volumes—for example, the popular Prusa MK4 has a build plate of 250x210x220mm, while budget printers like the Ender 3 V2 max out at 220x220x250mm. If your model exceeds these dimensions (like a life-sized figurine or a large functional part), splitting is non-negotiable.

But size isn’t the only reason. Large, solid models are prone to warping—a common issue where the edges of the print lift from the build plate as the plastic cools. Splitting a model into thinner sections reduces the amount of material cooling at once, minimizing this risk. I learned this firsthand when printing a 30cm tall robot model: the first attempt as a single piece warped so much the legs cracked, but splitting it into torso, arms, and legs resulted in a perfect print with no warping.

Another key benefit is material efficiency. If one part of a split model fails (e.g., a small arm breaks mid-print), you only need to reprint that section, not the entire model. This saves time, plastic, and frustration—especially important for expensive materials like resin or carbon-fiber filament.

Key Tools for Splitting 3D Models: Features and Comparisons

Choosing the right software is critical for successful model splitting. While some 3D slicers (like Cura) have basic splitting tools, dedicated software offers more control over seams, alignment, and part strength. Below is a comparison of the most popular tools, based on ease of use, features, and compatibility.

| Tool | Best For | Price | Key Features | Learning Curve |

| Meshmixer | Beginners, resin & FDM printers | Free | Automatic splitting, support for alignment pins, mesh repair | Low |

| Blender | Advanced users, custom splits | Free | Full 3D modeling tools, precise cut controls | High |

| 3D Builder | Windows users, quick splits | Free | Simple interface, built into Windows 10/11 | Very Low |

| Meshlab | Technical users, mesh analysis | Free | Powerful mesh editing, ideal for complex models | Medium |

| Fusion 360 | Functional parts, professional use | Free (hobbyists) | CAD tools, parametric splits, strength testing | Medium-High |

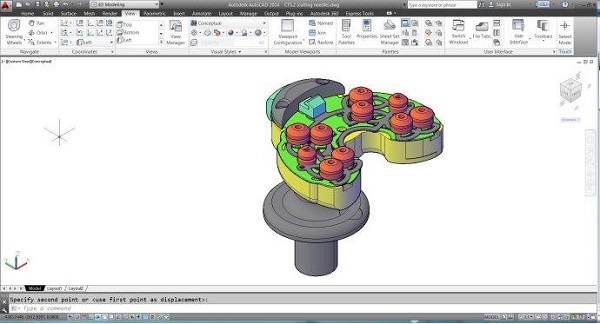

Real-World Example: When I needed to split a large automotive bracket for FDM printing, I used Fusion 360. Its parametric tools let me create custom alignment tabs that ensured the parts fit together perfectly, and I could run stress tests to make sure the split points wouldn’t break under load. For a resin print of a character bust, though, Meshmixer was faster—it automatically split the model at natural seams (like the neck and shoulders) and added small pins to align the parts during assembly.

Step-by-Step Guide to Splitting a 3D Model (Using Meshmixer)

Meshmixer is a great starting point for beginners because it’s free, user-friendly, and designed specifically for 3D printing workflows. Let’s walk through splitting a simple model (a 20cm tall vase) into two printable sections.

1. Prepare Your Model

First, download your 3D model (in STL or OBJ format) and open it in Meshmixer. Before splitting, check for mesh errors (like non-manifold edges or holes) that can cause issues during splitting. To do this:

- Go to Analysis > Inspector.

- Click “Auto-Repair” to fix small errors (e.g., missing faces).

- For larger errors, use the “Fill Hole” tool to close gaps.

Pro Tip: If your model has thin walls (less than 2mm), thicken them first using Edit > Offset (set to 0.5-1mm) to ensure the split parts are strong enough.

2. Choose Your Split Method

Meshmixer offers two main ways to split models:

- Plane Cut: Best for straight, simple splits (e.g., splitting a vase into top and bottom halves).

- Curve Cut: Ideal for complex shapes (e.g., splitting a figurine at the waist with a curved seam).

For our vase, we’ll use the Plane Cut:

- Go to Edit > Plane Cut.

- A blue plane will appear over your model—drag it to the desired split point (I placed mine 10cm from the bottom to create two equal sections).

- Use the rotation handles to adjust the plane’s angle (keep it horizontal for the vase).

3. Split and Separate the Parts

- Click “Cut” to split the model. You’ll see two overlapping sections.

- Go to Edit > Separate Shells—this will turn the two sections into separate objects.

- Use the “Move” tool (W key) to pull the parts apart and check for clean edges.

4. Add Alignment Features (Critical for Assembly)

The biggest mistake beginners make is skipping this step: without alignment tools, your parts may not fit together correctly. To add pins and holes:

- Select one part (e.g., the bottom of the vase) and go to Edit > Add Pin.

- Drag the pin to a corner of the split edge (add 2-3 pins for stability).

- Select the top part and go to Edit > Add Hole—align the hole with the pin on the bottom part.

- Adjust the pin/hole size (2-3mm diameter works for most PLA prints) to ensure a tight fit.

5. Export the Split Parts

- Select each part individually and go to File > Export.

- Save them as separate STL files (e.g., “vase_bottom.stl” and “vase_top.stl”).

- Double-check the file sizes to ensure they fit your printer’s build volume (use a slicer like Cura to preview).

Advanced Splitting Techniques for Complex Models

For models with intricate details (like characters, mechanical parts, or organic shapes), basic plane cuts won’t work. Here are two advanced techniques to get clean, functional splits.

1. Splitting Along Natural Seams

Complex models often have natural lines where splitting makes sense—for example, a character’s joints (elbows, knees), a chair’s legs, or a toy’s body parts. To find these seams:

- In Blender, use the “Edge Select” tool to highlight edges that follow the model’s shape.

- Go to Edit Mode > Mesh > Split > Split Edges to create a clean seam.

Case Study: A friend needed to print a 3D model of a dragon (40cm long) for a cosplay. Instead of splitting it into random sections, we used natural seams: the neck (between the head and body), the torso (between the chest and belly), and the tail (into three segments). This made assembly easier and kept the dragon’s shape intact—you can barely see the seams once painted.

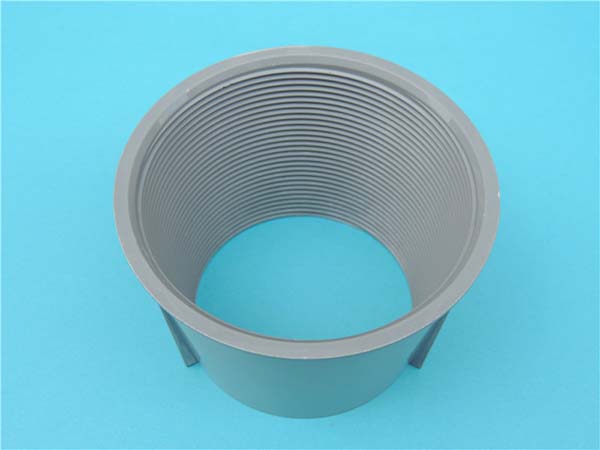

2. Splitting for Resin vs. FDM Printing

Resin and FDM printers have different requirements, so your splitting strategy should adapt:

- Resin Printing: Resin parts are often smaller and more detailed, so split models into sections that fit your resin tank (typically 150-200mm in height). Avoid thin splits (less than 1mm) because resin can leak between parts. Use “support blockers” in your slicer (like Chitubox) to protect delicate details near split edges.

- FDM Printing: FDM parts need more strength, so add reinforcement tabs (small, triangular sections) at split points to prevent breaking. For large parts, split them into sections that can be printed with minimal supports—for example, split a box into a base and lid instead of left and right halves (this reduces overhangs).

Common Mistakes to Avoid When Splitting 3D Models

Even with the right tools, small errors can ruin your print. Here are the most frequent mistakes and how to fix them:

- Ignoring Build Volume Limits: Always measure your printer’s build plate (length x width x height) before splitting. A common error is splitting a model into parts that are still too tall—for example, a 25cm part won’t fit on a printer with a 22cm height limit. Fix this by splitting the part vertically into smaller sections.

- Poor Seam Placement: Splitting a model across a detailed area (like a character’s face) will ruin the final look. Instead, place seams on less visible areas (e.g., the back of a figurine or the bottom of a functional part). Use the “Hide” tool in Meshmixer to preview how the seam will look from different angles.

- Forgetting Alignment Tools: Without pins or holes, your parts may shift during assembly. Even a 1mm misalignment can make a model unusable. Always add at least two alignment features per split—more for large parts.

- Over-Splitting: Splitting a model into too many parts (e.g., 10+ sections) increases assembly time and the risk of misalignment. Aim for the fewest splits possible—usually 2-4 parts for most models.

Yigu Technology’s Perspective on Splitting 3D Models for Printing

At Yigu Technology, we believe splitting 3D models is not just a workaround for small printers—it’s a strategy to improve print quality and versatility. Our team works with both hobbyists and industrial clients, and we’ve seen firsthand how smart splitting turns impossible prints into successful projects. For example, we helped a furniture designer split a large chair model into 6 parts that could be printed on a standard FDM printer; the final chair was lightweight but strong enough to hold 150kg, thanks to reinforced split points. We recommend beginners start with Meshmixer for simple splits and graduate to Blender or Fusion 360 for complex designs. The key is to prioritize function (strength, fit) and form (seam visibility) equally—this balance ensures your printed parts look great and work well.

FAQ: Splitting 3D Models for Printing

1. Can I split a model directly in my slicer (like Cura)?

Most slicers (including Cura) have basic splitting tools, but they’re limited. Slicers can split models along planes, but they don’t offer alignment features (pins/holes) or complex cuts. For simple splits (e.g., a cube), a slicer works—but for detailed models, use dedicated software like Meshmixer.

2. How do I know where to split a model for strength?

Avoid splitting across areas that will bear weight (e.g., the legs of a chair). Instead, split along areas with minimal stress—use Fusion 360’s “Simulation” tool to test where splits will be strongest. For example, a shelf should be split vertically (into left and right halves) instead of horizontally (top and bottom), because vertical splits distribute weight better.

3. Do I need to sand the split edges before assembly?

Yes—split edges often have small burrs or rough spots. Sand them with fine-grit sandpaper (200-400 grit) to create a smooth surface. For resin parts, use a resin file to trim excess material before sanding.

4. What glue should I use to assemble split 3D parts?

For PLA or PETG (FDM prints), use cyanoacrylate glue (super glue) with a baking soda activator (this speeds up drying and adds strength). For resin parts, use epoxy glue (it’s stronger and bonds well to smooth resin surfaces). Avoid white glue—it’s too weak for 3D printed parts.

5. Can I split a model that’s already been sliced?

No—you need to split the original STL/OBJ file before slicing. Sliced files (like G-code) are optimized for printing and can’t be edited to split parts. Always split the model first, then slice each part separately.