Finding a comfortable, functional, and affordable prosthetic arm often leads to disappointing results: standard solutions rarely fit anyone perfectly. Traditional prosthetics can be heavy, extremely expensive, and require long, difficult fitting processes. This situation can feel discouraging, but new technology is completely changing everything. We are entering a time where a custom prosthetic arm 3d model works as the digital plan for a device that truly becomes part of the person. This method puts the power of customization directly into the hands of users, doctors, and makers.

This guide will be your complete roadmap. We will walk through the entire process, from understanding the basic technology to creating a real, working device. Our exploration will cover:

- The problems with traditional prosthetics and how 3D modeling offers a better solution.

- The essential hardware and software tools you will need to get started.

- A detailed, step-by-step process for designing and making a patient-specific prosthetic arm.

- Important information about materials to ensure your device is safe, strong, and functional.

- A look into the exciting future of this rapidly growing field.

3D Modeling: A Revolution

The change from traditional manufacturing to digital creation represents a major shift in how we approach prosthetics. Using a prosthetic arm 3d model as the foundation is not just a new method; it's a complete change that fixes the main problems of older systems. The benefits are not small improvements—they are life-changing, affecting everything from user comfort to worldwide access.

Better Customization and Fit

Traditional methods often involve plaster casting, a process that is messy, time-consuming, and only captures a still impression of the remaining limb. The resulting socket may fit poorly, creating pressure points and discomfort. In contrast, 3D scanning captures the detailed, unique shape of a limb with extremely precise measurements. This digital information allows us to design a socket that fits perfectly to the user's body. We can digitally create relief areas for sensitive bone areas and adjust measurements with incredible accuracy. We've seen how even a few millimeters of adjustment in the digital model can prevent pressure sores and greatly improve daily comfort for the user. Appearance is also fully customizable, allowing for designs, colors, and shapes that reflect the user's personality.

Lower Costs, Greater Access

The financial barrier to getting a functional prosthesis is one of the biggest challenges in the field. Traditional electronic arms can cost anywhere from $10,000 to over $100,000, placing them far out of reach for most of the world's population. This is where 3D printing delivers its most powerful impact. By using open-source designs and affordable materials, a highly functional, cable-operated or basic electronic prosthetic arm 3d model can be produced for under $500 in materials. This huge cost reduction makes access possible for everyone, making it possible for individuals, schools, and non-profits anywhere in the world to create life-changing devices.

Fast Design and Production

The timeline for receiving a traditional prosthesis can take weeks or even months, involving multiple appointments for casting, fitting, and adjustments. The digital workflow shortens this timeline dramatically. A 3D scan can be completed in minutes. Modifying a prosthetic arm 3d model might take a few hours, and printing the components can be done overnight. It is now possible to go from initial scan to a wearable prototype in just a few days. This speed is especially important for child users, who outgrow their prostheses quickly. A new, larger device can be printed and assembled in a fraction of the time and cost.

Empowerment Through Improvement

A traditional prosthesis is a closed system. If a part breaks, it often requires a costly and lengthy repair process involving a specialist. With a 3D printed device, the user has control. The digital blueprint, the prosthetic arm 3d model, is a file that can be endlessly modified and improved. If a finger component breaks, a replacement can be printed at home or in a local workshop for a few cents. If the fit of the socket needs a minor adjustment, the model can be changed and a new version printed. This improvement process encourages independence, encourages experimentation, and gives the user complete control over the device they depend on daily.

Your Essential 3D Toolkit

Starting the journey of creating a custom prosthetic requires a specific set of tools. While the technology may seem complex, it has become more accessible and affordable than ever. We can break down the essential toolkit into three distinct stages: capturing the shape, designing the device, and creating the physical object.

Step 1: Capturing Body Shape

The foundation of any patient-specific device is an accurate digital copy of the user's remaining limb. This is achieved with 3D scanners, which translate physical shape into digital data. The choice of scanner depends on your budget and required accuracy.

- Structured-Light Scanners: These are the professional's choice, often found in medical settings. They project a pattern of light onto the subject and analyze how it bends to create a highly accurate and detailed mesh. While expensive, they provide the cleanest data for medical applications.

- Handheld Infrared Scanners: Taking a middle ground between cost and quality, scanners from brands like Revopoint or Creality offer excellent accuracy for prosthetics work. They are portable, relatively easy to use, and are a great investment for dedicated makers or small clinics.

- Photo-Based Apps: This is the most accessible starting point. Using just a smartphone, photo-based software stitches together dozens or hundreds of photos to create a 3D model. The quality depends heavily on lighting and user technique, and the resulting models require significant digital cleanup. However, for initial prototypes or non-critical applications, it is a powerful, no-cost option.

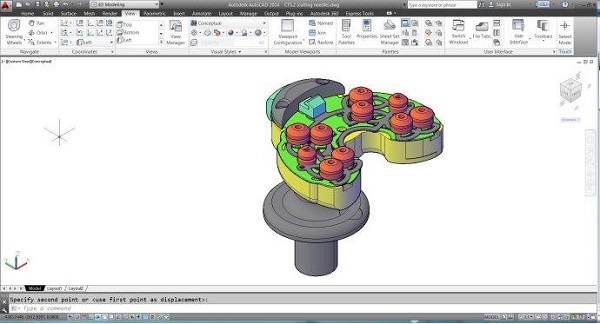

Step 2: Digital Sculpting

Once you have a 3D scan, the next step is to bring it into a software environment where you can clean it up, design the socket, and integrate the mechanical components. This is where the prosthetic arm 3d model truly takes shape. The software landscape is diverse, catering to different skill levels and tasks.

| Software | Best For | Skill Level | Cost |

| Meshmixer | Beginners, scan cleanup, simple edits, hollowing | Beginner | Free |

| Fusion 360 | Precise mechanical design, integrating parts | Intermediate | Free (Hobbyist) |

| Blender | Organic sculpting, advanced mesh manipulation | Intermediate | Free |

| Geomagic Freeform | Advanced medical modeling with touch feedback | Professional | Paid |

For most users, a combination of Meshmixer for initial scan cleanup and Fusion 360 for the precise mechanical design of the socket and assembly offers a powerful and cost-effective workflow.

Step 3: Bringing it to Life

The final stage of the digital workflow is turning your carefully designed prosthetic arm 3d model into a physical object. This is the domain of 3D printers.

- FDM (Fused Deposition Modeling) Printers: This is the technology of choice for prosthetic applications due to its affordability, strength of materials, and ease of use. These printers work by pushing out a thin strand of plastic layer by layer to build up an object.

- Printer Considerations: When choosing a printer, the most important factor is build volume. You must ensure the print bed is large enough to accommodate the largest single part of your design, typically the forearm or socket. Reliability is also key; look for printers with a strong community and proven track record. A heated print bed is essential for printing with materials like PETG, which are ideal for structural components.

- Material Introduction: The plastic filament used by the printer is as important as the printer itself. Different materials have very different properties. The most common choices for prosthetics are PLA+, PETG, and TPU, each serving a specific purpose that we will explore in greater detail later.

The Step-by-Step Workflow

With the right tools in hand, we can now walk through the process of creating a custom prosthesis. This workflow transforms the abstract concept of a prosthetic arm 3d model into a repeatable, actionable set of steps. Following this sequence carefully is the key to a successful outcome.

Step 1: The Digital Impression

The first practical step is to get a high-quality 3D scan of the user's remaining limb. A clean scan is the foundation of a comfortable socket. During this process, ensure the user maintains a stable and relaxed posture. If using photo-based methods, lighting is critical—it must be bright and even, without harsh shadows. Capture the entire limb from multiple angles, ensuring significant overlap between photos or scanner passes. A helpful tip from our experience: take two separate scans. First, with the user's muscles completely relaxed. Second, with their muscles tensed. Comparing these two models helps us identify areas of muscle movement and design a socket that accommodates the limb's changing shape, preventing pinching or excessive pressure during use.

Step 2: Data Cleanup

Raw scan data is almost never perfect. It will contain "noise," holes, and other digital problems. Before any design work can begin, this data must be cleaned. We use software like Autodesk Meshmixer or Blender for this task. The primary goal is to create a "watertight" or "solid" mesh, meaning a solid object with no holes. This involves using sculpting tools to smooth rough areas, digitally patching any gaps in the mesh, and removing any floating, disconnected pieces of data. This clean, solid model of the limb is the positive mold we will build the socket around.

Step 3: The Socket Design

This is the most critical and skill-intensive phase of the process. The socket is the interface between the user and the device; its comfort determines the success of the entire prosthesis. We import the cleaned limb model into a CAD program like Fusion 360. The process involves creating a "boolean" or "subtraction" operation. First, we model the external shape of the socket. Then, we use the limb scan as a tool to cut away the inside, creating a cavity that perfectly matches the user's anatomy.

Here, we introduce two vital concepts. First is "offsetting." We create a small offset (typically 1-3mm) between the limb model and the inner socket wall to create space for a soft liner material. Second is creating "reliefs." We identify bony or sensitive areas on the limb model and create small, targeted voids or pockets in the socket wall over these spots to eliminate pressure. This highly detailed customization of the prosthetic arm 3d model is what sets this method apart.

Step 4: Integrating Components

Once the custom socket is designed, we must integrate it with the functional parts of the arm—the forearm, wrist, and terminal device (hand or gripper). A wealth of open-source designs are available from communities like e-NABLE or Thingiverse. We import the prosthetic arm 3d model files for these components into our CAD project. The key task here is scaling. We measure the user's healthy limb to ensure the prosthetic arm is proportional. We scale the forearm, hand, and finger models appropriately and then digitally merge them with our custom-designed socket, ensuring all connection points are strong and correctly aligned.

Step 5: Slicing and Printing

With the complete prosthetic arm 3d model assembled, it's time to prepare it for 3D printing. This is done using a "slicer" program (e.g., Cura, PrusaSlicer). The slicer converts the 3D model into hundreds or thousands of individual layers and generates the G-code instructions the printer follows. Slicer settings are critical for the strength and quality of the final parts.

- Layer Height: A setting of 0.2mm provides a good balance between print speed and part strength.

- Infill: This is the internal support structure. We use a higher infill percentage (40-60% grid or honeycomb pattern) for high-stress structural parts like the socket connection. For cosmetic or low-stress parts like fingers, 20% is sufficient.

- Wall/Perimeter Count: This is one of the most important settings for strength. We always use a minimum of 3-4 walls (perimeters) for all structural components. This creates a thick, solid outer shell that bears the majority of the load.

- Supports: 3D printers cannot print on thin air. Overhangs and bridges require support structures. The slicer can generate these automatically. We use settings that make the supports strong enough to hold the part during printing but easy to break away cleanly afterward.

Step 6: Post-Processing

After many hours of printing, the components are ready for assembly. The first step is carefully removing all support material. The inner surface of the socket, which will be in contact with the liner, should be lightly sanded to ensure it is perfectly smooth with no sharp edges. From there, we follow the assembly instructions for the chosen open-source design. This typically involves using screws, bolts, and non-stretch "tendon" lines (like fishing line or strong cord) to connect the fingers and movement system. Finally, we add padding and the soft socket liner, and perform a final test fit with the user, making notes for any minor adjustments needed for the next version.

Material Science for Prosthetics

Choosing the right 3D printing filament is not a minor detail; it is fundamental to the safety, durability, and function of the prosthesis. Simply using any "plastic" is a recipe for failure. Understanding the properties of different materials allows us to assign them to roles for which they are best suited within the prosthetic arm 3d model assembly.

Main Filaments: PETG vs PLA+

For the main structural components—the socket, forearm, and palm—we need materials that are strong, durable, and resistant to impact. The two leading candidates in the consumer space are PETG and PLA+.

| Feature | PETG (Polyethylene Terephthalate Glycol) | PLA+ (Polylactic Acid Plus) |

| Strength | Excellent layer bonding and impact resistance. | Stronger in pulling tests, but can be more brittle. |

| Flexibility | Has a slight amount of give, making it less prone to breaking. | More rigid and stiff. |

| Heat Resistance | High melting temperature; will not deform in a hot car. | Low melting temperature; can warp or soften in direct sun or a hot car. |

| Best For | Sockets, forearms, and any part requiring durability and heat resistance. | Fingers, cosmetic covers, and prototypes not intended for harsh environments. |

In our experience, PETG is the superior all-around choice for the primary structural parts of a prosthetic arm. Its durability and higher heat resistance provide a crucial margin of safety for a device that will be used daily in various environments. PLA+ is a good alternative for less critical components or for rapid prototyping.

Comfort and Grip with TPU

Rigid plastics are not suitable for every part of a prosthesis. For components that need to be soft, flexible, or provide grip, we turn to TPU (Thermoplastic Polyurethane). This rubber-like filament is ideal for several applications:

- Grip Surfaces: Printing the fingertips or palm pads in TPU provides a high-friction surface that dramatically improves the ability to hold objects like a cup or a phone.

- Flexible Joints: In some designs, TPU can be used as a flexible hinge or a spring element.

- Socket Liners: While a separate foam liner is common, it is possible to print a thin, flexible inner liner directly from TPU, which can conform to the limb and provide cushioning.

Printing with TPU can be challenging and typically requires a printer with a "direct drive" extruder to prevent the flexible filament from buckling. It must be printed slowly, but the functional benefits it provides are well worth the effort.

Safety Considerations

Any material that will be in prolonged contact with the skin requires careful consideration. It's important to state clearly that standard consumer-grade filaments like PETG and PLA are not medically certified as safe for body contact. While PETG is chemically stable and generally considered non-toxic (it's the same family of plastic used in water bottles), we do not recommend direct, long-term skin contact. The best practice, and the one we always follow, is to use a physical barrier. A prosthetic sock, made from cotton or a specialized moisture-wicking fabric, should always be worn between the remaining limb and the socket. This prevents skin irritation and manages perspiration.

For clinical applications requiring certified materials, medical-grade filaments do exist. These have been tested according to standards like ISO 10993, which evaluates the biological response to materials. However, these filaments are significantly more expensive and often unnecessary for community-driven or personal projects where a simple prosthetic sock provides an effective and safe barrier.

The Future is Now

The field of 3D printed prosthetics is evolving at an incredible pace. What seems like science fiction today is rapidly becoming a practical reality. Looking ahead, several key trends are set to further enhance the capabilities of the prosthetic arm 3d model and the devices they create.

Advanced Electronic Integration

We are moving beyond simple cable-operated devices. Affordable muscle sensors, like the MyoWare sensor, can be integrated directly into a 3D printed prosthesis. These sensors detect the electrical signals in a user's muscles (EMG signals) and translate them into commands, such as opening or closing the hand. This allows for the creation of low-cost, functional electronic hands that were previously only available for tens of thousands of dollars.

Multi-Material Printing

Currently, we print rigid and flexible parts separately and assemble them. The next frontier is multi-material 3D printing. Emerging technologies will allow a single printer to use multiple materials in one print job. Imagine printing a socket that is rigid on the outside but transitions seamlessly to a soft, cushioned TPU on the inside, all in a single, automated process.

AI-Powered Design Automation

The most time-consuming part of the workflow is the manual design of the socket. In the near future, we expect that Artificial Intelligence will automate much of this process. An AI algorithm could analyze a 3D scan of a remaining limb, automatically identify pressure-sensitive areas and muscle groups, and generate a perfectly optimized prosthetic arm 3d model for the socket in minutes, not hours.

Global Open-Source Collaboration

Perhaps the most powerful trend is the human one. Global communities like e-NABLE connect thousands of volunteers, designers, and engineers with individuals in need. They work together to develop and share open-source prosthetic arm 3d model files for free. This global, decentralized network of makers is a powerful force for good, ensuring that the benefits of this technology reach those who need it most, regardless of their location or financial means.

Your Journey Starts Here

We have traveled from the concept of a digital model to the reality of a physical, functional device. The main message is one of major change and empowerment. Creating a patient-specific prosthesis using a prosthetic arm 3d model is no longer a futuristic dream but an accessible and transformative process that is reshaping lives today.

This guide has shown that 3D modeling and printing offer a path to prosthetics with unmatched customization, dramatic affordability, and unprecedented speed.

- Personalization is key: A perfect, comfortable fit is not a luxury; it is now the achievable standard.

- The technology is accessible: The tools, software, and knowledge are within reach of dedicated individuals, clinics, and communities.

- The process is systematic: By following a clear and logical workflow, you can reliably move from a digital scan to a functional device.

- You are empowered: This technology shifts control from a closed, expensive industry into the hands of the user and creator.

The power to design, create, and improve is at your fingertips. The tools are ready, the community is waiting, and the potential is limitless. Start your journey today and build a solution that is uniquely yours.