What is 3D Printing for Production Parts?

3D printing for production parts, also known as additive manufacturing, is a revolutionary technology that creates three - dimensional solid objects from a digital file. Instead of subtracting material like traditional manufacturing methods such as machining, 3D printing builds parts layer by layer.

The process begins with a 3D model, which can be created using computer - aided design (CAD) software or obtained through 3D scanning. This digital model is then sliced into thin cross - sectional layers by specialized software. The 3D printer reads these sliced files and deposits materials, such as plastics, metals, ceramics, or composites, one layer at a time until the entire part is formed. For example, in fused deposition modeling (FDM), one of the most common 3D printing techniques, a thermoplastic filament is melted and extruded through a nozzle to build up the layers. In selective laser sintering (SLS), a high - power laser fuses powdered materials together to create the part.

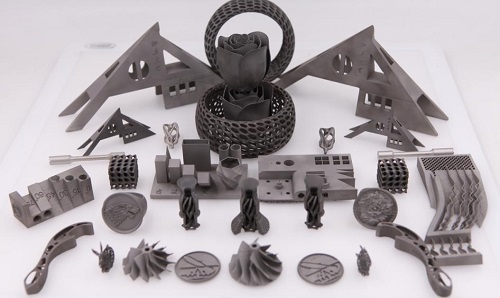

This technology has opened up new possibilities for manufacturing. It allows for the production of highly complex geometries that would be extremely difficult or even impossible to achieve with traditional methods. For instance, parts with internal cavities, intricate lattice structures, or organic - like shapes can be easily fabricated using 3D printing. It also enables on - demand production, reducing the need for large - scale inventory storage. Instead of manufacturing a large batch of parts all at once, companies can produce parts as they are needed, which is especially beneficial for low - volume production runs or custom - made components.

How Does 3D Printing Work?

Key Elements

3D printing involves several key elements. The first is the digital file, which serves as the blueprint for the 3D - printed part. This file contains all the geometric information about the object to be printed, including its shape, size, and internal structures. For example, a CAD file created by a designer is a common type of digital file for 3D printing.

The 3D printer is the physical device that brings the digital file to life. It reads the sliced layers from the digital file and deposits materials layer by layer according to the instructions. Different types of 3D printers are designed for different applications and materials, with each having its own set of features and capabilities.

Materials are another crucial element. There is a wide variety of materials available for 3D printing, such as plastics like ABS (acrylonitrile - butadiene - styrene) and PLA (polylactic acid), metals like titanium and aluminum, ceramics, and even some specialized materials like biocompatible polymers for medical applications. Each material has its own properties, such as strength, flexibility, heat resistance, and chemical resistance, which determine its suitability for different production parts.

Main Technologies

There are several main 3D - printing technologies, each with its own working principle, advantages, and disadvantages.

- Fused Deposition Modeling (FDM): In FDM, a thermoplastic filament is fed into a heated extruder nozzle. The nozzle melts the filament and deposits it layer by layer onto a build platform, following the cross - sectional patterns from the sliced digital file. For example, a common desktop 3D printer often uses FDM technology. Advantages: It is relatively inexpensive, easy to use, and has a wide range of available materials. The operation is also clean and safe, suitable for home and small - scale production. Disadvantages: The surface finish of the printed parts is usually rough, and the printing speed is relatively slow. It also requires support structures for overhanging parts. Suitable materials: PLA, ABS, PETG (polyethylene terephthalate glycol - modified), etc.

- Stereolithography (SLA): SLA uses a vat of liquid photopolymer resin and a UV laser. The laser traces the cross - sectional shape of each layer onto the surface of the resin, causing the resin to solidify and form the layer. After each layer is cured, the build platform is lowered, and a new layer of resin is applied. Advantages: It offers high precision and excellent surface quality, making it ideal for creating detailed and smooth - surfaced parts, such as jewelry prototypes or dental models. Disadvantages: The equipment and materials are relatively expensive, and the resin is often toxic and needs to be handled with care. Also, the printed parts may be brittle and have limited mechanical strength. Suitable materials: Various types of photopolymer resins.

- Three - Dimensional Printing (3DP): 3DP works by spreading a layer of powder (such as plaster, ceramic, or metal powder) onto a build platform. Then, a binder is selectively sprayed onto the powder to bond the particles together in the shape of the desired layer. This process is repeated until the entire part is formed. Advantages: It can create complex internal structures without the need for support structures, and it allows for multi - color printing by adding pigments to the binder. Disadvantages: The printed parts generally have a lower strength compared to some other 3D - printing methods and may require post - processing to increase their durability. Suitable materials: Powder - based materials like plaster powder, metal powder, etc.

- Selective Laser Sintering (SLS): SLS uses a high - power laser to sinter powdered materials (such as nylon, metal, or ceramic powder) together. The laser scans the cross - sectional pattern of each layer onto the powder bed, melting and fusing the powder particles in the scanned areas. Advantages: It can produce parts with high strength and good mechanical properties, and it can use a variety of materials. There is no need for support structures as the unsintered powder supports the overhanging parts. Disadvantages: The equipment is expensive, the process can be time - consuming, and the surface finish of the parts may be rough, often requiring post - processing. Suitable materials: Nylon, metal powders (e.g., stainless steel, titanium), ceramic powders, etc.

Applications of 3D Printing in Different Industries

3D printing for production parts has found its way into a wide range of industries, revolutionizing the manufacturing process in each of them.

Automotive Industry

In the automotive industry, 3D printing is used for manufacturing custom - made components and rapid prototyping. For example, Tesla uses 3D printing to produce some of its car parts. In the Model Y, 3D printing technology has enabled the integration of 70 different parts into just one, streamlining the production process. This not only reduces the complexity of assembly but also cuts down on production time and cost.

Another example is BMW, which has been using 3D printing for 30 years. It has been applied to produce parts, tools, and auxiliary equipment. In 2023, more than 400,000 parts were produced through 3D printing globally in BMW. The use of 3D - printed robot grippers in BMW's factories has reduced their weight by about 20% - 30%, improving the efficiency and durability of production lines. The technology allows car manufacturers to quickly test new designs and make adjustments before mass production, significantly shortening the development cycle of new models.

Aerospace Industry

Aircraft and spacecraft require parts that are both lightweight to reduce fuel consumption and strong enough to withstand extreme conditions. 3D printing enables the creation of parts with intricate lattice structures that are much lighter than traditional solid parts but still maintain high strength. For instance, Airbus has been actively using 3D printing to produce components for its aircraft. By using 3D - printed parts, the weight of the aircraft can be reduced, leading to lower fuel consumption and costs, and at the same time, improving the overall performance of the aircraft. In the production of rocket engines, 3D printing can create complex fuel nozzles and combustion chambers with high precision, enhancing the efficiency and reliability of the engines.

Medical Field

3D printing has made remarkable contributions to the medical field, especially in the production of personalized prosthetics and implants. For example, the E - nable association in the US has donated hundreds of 3D - printed prosthetics to people in need around the world since 2013. These prosthetics are customized to fit each patient perfectly, providing a better fit and functionality compared to traditional, one - size - fits - all prosthetics.

In the area of implants, 3D - printed spinal implants can be designed to match the unique anatomy of each patient, promoting better integration with the body and faster recovery. A study from the University of California, San Diego showed that researchers used 3D - printed spinal scaffolds loaded with neural stem cells and implanted them into rats with severely damaged spinal cords. The result was that the rats successfully recovered their motor functions. This indicates the great potential of 3D - printed implants in treating complex medical conditions and improving patients' quality of life.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology believes that 3D printing has brought about a significant transformation in the production of parts. It enables the manufacturing of parts with complex structures that were previously unachievable through traditional methods. For example, parts with intricate internal channels or unique geometries can now be produced with relative ease. This technology also offers the advantage of personalized customization. We can create parts tailored to the specific needs of our clients, whether it's for a small - scale project or a one - of - a - kind product.

However, we also recognize that there are challenges. The high cost of some 3D - printing equipment and materials, as well as the relatively slow printing speed, can limit its widespread application in some cases. But overall, we are optimistic about the future of 3D printing in the production of parts. With the continuous development of technology, we believe that there will be greater breakthroughs, making 3D printing an even more integral part of the manufacturing process.

FAQ

What materials can be used for 3D printing production parts?

A wide range of materials can be used for 3D printing production parts. Polymer materials like ABS (acrylonitrile - butadiene - styrene) are strong and heat - resistant, suitable for making durable parts such as automotive interior components. PLA (polylactic acid), on the other hand, is biodegradable and easy to print, often used for prototypes and educational models. Metal materials include aluminum alloys, which are lightweight and corrosion - resistant, ideal for aerospace components. Titanium alloys are extremely strong and biocompatible, making them suitable for medical implants and high - performance aerospace parts. Photopolymer resin materials are used in SLA (Stereolithography) 3D printing. They can create highly detailed parts with smooth surfaces, for example, in jewelry making and dental applications. Inorganic non - metal materials such as ceramics can be 3D - printed to produce high - temperature - resistant and wear - resistant parts, like engine components in high - temperature environments.

How accurate is 3D printing for production parts?

The accuracy of 3D printing for production parts depends on multiple factors, including the type of printer, the technology used, the material, and the printing parameters. Generally, the accuracy can range from 0.1 - 0.4 millimeters in common 3D printers. For example, in Fused Deposition Modeling (FDM), which is a popular and relatively low - cost 3D - printing technology, the typical accuracy is around this range. However, with high - end industrial 3D printers and advanced technologies like SLA (Stereolithography) or some high - precision metal 3D - printing processes, the accuracy can reach up to 0.01 millimeters. For parts with low - accuracy requirements, such as some simple prototypes for form and fit testing, FDM printers can be sufficient. But for parts in the aerospace or medical fields, like a small, precisely - sized component in an aircraft engine or a customized dental implant, high - precision 3D - printing technologies are needed to meet the strict dimensional tolerances.

Can 3D printing replace traditional manufacturing methods for production parts?

3D printing has its unique advantages, such as the ability to create complex geometries, on - demand production, and reduced material waste. However, it cannot completely replace traditional manufacturing methods at present. For small - batch production and custom - made parts, 3D printing shines. It allows for quick production of unique parts without the need for expensive molds, as is the case in traditional injection molding. For example, a small - scale jewelry maker can use 3D printing to create one - of - a - kind jewelry pieces. But for large - scale, standardized production, traditional manufacturing methods like injection molding or stamping are more cost - effective and efficient. They can produce a large number of identical parts in a short time. In the future, 3D printing and traditional manufacturing methods are more likely to complement each other. Traditional manufacturing can handle mass production, while 3D printing can be used for prototyping, custom parts, and producing components with complex structures that are difficult to manufacture through traditional means.