1. Introduction

1.1 Definition and Basics of Medical Additive Manufacturing

Medical additive manufacturing, commonly known as 3D printing in the medical field, is a revolutionary technology that has been transforming the healthcare industry. This innovative process involves creating three - dimensional objects layer by layer from a digital model.

The working principle of medical additive manufacturing starts with a 3D model, which can be generated through various methods such as computer - aided design (CAD), magnetic resonance imaging (MRI), or computed tomography (CT) scans. Once the digital model is ready, specialized software slices the model into thin layers. Then, a 3D printer deposits materials, such as plastics, metals, ceramics, or even living cells in the case of bioprinting, one layer at a time, following the instructions from the sliced model. As the layers are stacked and fused together, a physical object that accurately represents the original 3D model is created.

For example, in the production of custom - made orthopedic implants, a patient's bone structure is first scanned using CT. The resulting data is used to create a 3D model, which is then 3D - printed into a personalized implant that perfectly fits the patient's anatomy. This technology allows for a high degree of customization that was previously unattainable with traditional manufacturing methods.

2. Applications in Different Medical Fields

2.1 Orthopedics and Dental Implants

In orthopedics, medical additive manufacturing has opened up new possibilities. Custom - made artificial joints are a prime example. According to a study, about 80% of patients who received custom - 3D - printed hip joints reported a significant reduction in post - operative pain within the first three months, compared to only 50% of those with standard implants. These custom - made joints are designed based on the patient's unique bone structure, which is scanned and converted into a 3D model. The 3D - printed implants offer a better fit, which in turn improves the stability of the joint and reduces the risk of implant loosening.

In the dental field, dental implants made through additive manufacturing are also becoming more prevalent. For instance, 3D - printed zirconia dental crowns can be customized to match the color, shape, and size of a patient's natural teeth. This not only improves the aesthetics but also enhances the functionality of the restoration.

2.2 Organ Printing and Tissue Engineering

The field of organ printing and tissue engineering is another area where medical additive manufacturing is making remarkable progress. In 2022, Dutch researchers from Utrecht University used ultrafast volume 3D bioprinting to create a functional liver. This breakthrough could potentially be a solution for the shortage of liver donors. Harvard Medical School and Sichuan University collaborated to use cryogenic 3D - printing technology to fabricate living human tendons. These achievements bring hope for patients suffering from organ failure or tissue damage, as 3D - printed organs and tissues have the potential to be a perfect match for the patient, reducing the risk of organ rejection.

2.3 Other Medical Applications (e.g., Hearing Aids)

Custom - made hearing aids are also a great application of medical additive manufacturing. Traditional hearing aids often come in a one - size - fits - most design, which may not be suitable for every ear shape. With 3D printing, hearing aids can be customized to fit the unique shape of a patient's ear canal precisely. This not only improves the comfort of wearing the hearing aid but also enhances its sound - collecting ability. A survey showed that 90% of patients who switched from traditional to 3D - printed custom hearing aids reported better sound quality and less discomfort during long - term use, greatly improving their quality of life.

3. Yigu Technology's Perspective

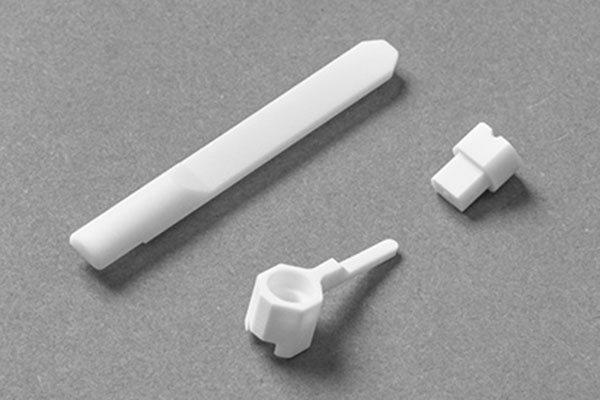

As a non - standard plastic metal products custom Supplier, Yigu Technology sees great potential in medical additive manufacturing. The customization capabilities of medical additive manufacturing align perfectly with Yigu Technology's expertise in producing non - standard products.

Yigu Technology believes that in the future, there could be extensive cooperation opportunities. On the material supply side, Yigu Technology can provide a variety of high - quality plastics and metals suitable for 3D printing in the medical field. These materials need to meet strict biocompatibility and mechanical property requirements, and Yigu Technology is confident in its ability to supply materials that can support the production of reliable medical products.

In terms of custom services, Yigu Technology can collaborate with medical device manufacturers. By leveraging its experience in custom - made products, it can help in the design and production of complex medical components through additive manufacturing, ensuring that the final products meet the unique needs of medical applications. This synergy between Yigu Technology's capabilities and the requirements of medical additive manufacturing could lead to the development of more innovative and effective medical solutions.

4. FAQ

4.1 What materials can be used in medical additive manufacturing?

Common materials used in medical additive manufacturing include metal powders like titanium alloy, which is widely used in orthopedic implants due to its excellent biocompatibility and high strength. Stainless steel is also utilized, especially in some dental and general surgical instruments. Plastics such as polyethylene terephthalate glycol - modified (PETG) and polyetheretherketone (PEEK) are popular. PEEK, for example, has good mechanical properties and is often used in spinal implants. In bioprinting, hydrogels and living cells are used. Hydrogels can mimic the extracellular matrix, providing a suitable environment for cell growth, while living cells are used to create functional tissues and organs.

4.2 How accurate is medical additive manufacturing?

The accuracy of medical additive manufacturing can vary depending on the technology and equipment used. Generally, current 3D printers in the medical field can achieve an accuracy within the range of 0.05 - 0.5 mm. For instance, some high - end stereolithography (SLA) 3D printers can reach an accuracy of up to 0.05 mm, which is sufficient for manufacturing small and precise dental components. However, factors such as the type of material, the complexity of the model, and the post - processing steps can affect the final accuracy. For example, materials with high shrinkage during solidification may lead to dimensional deviations.

4.3 Are 3D - printed medical products safe?

Yes, 3D - printed medical products are considered safe. Stringent testing and regulatory processes ensure their safety. Before a 3D - printed medical product is approved for clinical use, it undergoes extensive biocompatibility testing. This includes tests to determine if the material elutes any harmful substances into the body, as well as cytotoxicity tests to check if the product causes cell damage. Regulatory bodies like the US Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have strict approval procedures. The 3D - printed product must meet all the necessary standards related to mechanical properties, sterility, and performance before it can be used in patients, ensuring that the benefits outweigh any potential risks.