Introduction

Definition and Basics of SLS 3D Printing Technology

Have you ever wondered how a technology can transform a digital design into a tangible, three - dimensional object with remarkable precision? That's where SLS 3D printing technology comes in. SLS, short for Selective Laser Sintering, is a revolutionary 3D printing method that has been making waves in various industries.

Definition: SLS 3D printing is a powder - bed fusion additive manufacturing process. It was developed by Dr. Carl Deckard at the University of Texas at Austin in 1989. The technology uses a high - power laser (such as a CO₂ laser) as the energy source. It selectively fuses powdered materials, layer by layer, according to the cross - sectional data of the three - dimensional model obtained from a CAD (Computer - Aided Design) file. Once the laser sinters the powder in a particular layer, a new layer of powder is spread over the previously sintered layer, and the process repeats until the entire 3D object is formed.

In the Realm of 3D Printing: SLS holds a significant position in the 3D printing landscape. While there are other 3D printing techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Melting (SLM), SLS stands out for several reasons. FDM is more commonly used for hobbyists and low - cost applications as it extrudes melted filament to build objects layer by layer. SLA uses a laser to cure liquid resin, mainly for high - detail and smooth - surface applications. SLM is similar to SLS but is specifically designed for fully melting metal powders to create dense metal parts.

SLS, on the other hand, offers a unique combination of features. It can work with a wide range of materials, including polymers (such as nylon), metals, ceramics, and composites. This versatility makes it suitable for applications ranging from rapid prototyping in product design to manufacturing end - use parts in industries like aerospace, automotive, and healthcare. For example, in the aerospace industry, SLS - printed parts can be used to create lightweight yet strong components, reducing the overall weight of aircraft and improving fuel efficiency.

How SLS 3D Printing Technology Works

The Principle of SLS 3D Printing

The principle of SLS 3D printing is centered around the concept of powder - bed fusion. At its core, SLS uses a high - power laser to selectively heat and sinter powdered materials. When the laser beam hits the powder particles, the heat causes the powder to reach a temperature near or at its melting point, fusing the particles together. This sintering process is crucial as it allows the creation of solid structures from loose powder.

The energy from the laser beam is carefully controlled. For example, in the case of nylon powder, which is commonly used in SLS 3D printing, the laser needs to provide enough energy to sinter the nylon particles but not so much that it causes over - melting or damage to the material properties. The sintering process occurs at a molecular level. As the laser heats the powder, the molecules of the powder material start to bond with each other. This bonding forms a solid mass that adheres to the previously sintered layers, gradually building up the 3D object layer by layer.

The Specific Process of SLS 3D Printing

- Data Preparation:

- First, you need to create a 3D model of the object you want to print using CAD software. This model contains all the geometric information of the final product. Once the model is ready, it is saved in a format (usually STL - Stereolithography) that can be recognized by the 3D printer's software.

- The next step is slicing. Specialized slicing software takes the 3D model and divides it into thin, horizontal cross - sections. Each cross - section represents a layer that will be printed. The slicing software also generates the G - code, which is a set of instructions that tells the 3D printer how to move the laser, where to sinter the powder, and how thick each layer should be. Layer thicknesses in SLS 3D printing typically range from 0.05 mm to 0.2 mm, depending on the desired level of detail and the material being used.

- Printer Setup and Powder Loading:

- The SLS 3D printer has a build chamber where the printing process takes place. Before starting, the build chamber is filled with the appropriate powder material. This powder is usually stored in a hopper and is then transferred to the build area.

- The printer's internal components, such as the laser system, powder spreading mechanism, and temperature control system, are calibrated to ensure accurate operation. Temperature control is crucial as the powder needs to be pre - heated to a specific temperature just below its melting point. This pre - heating helps to reduce thermal stress during the sintering process and improves the quality of the final part. For instance, when using polyamide powder, the build chamber might be pre - heated to around 180 - 200°C.

- Printing Process:

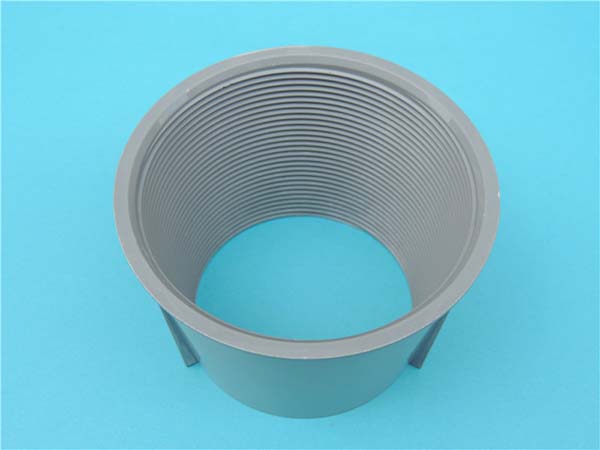

- Powder Spreading: A recoater or a powder - spreading mechanism spreads a thin layer of powder evenly across the build platform. This layer of powder serves as the raw material for the current layer of the 3D object. The recoater ensures that the powder layer has a consistent thickness and is free of any clumps or uneven areas.

- Laser Scanning: Once the powder is spread, the high - power laser beam is activated. The laser moves across the powder layer according to the instructions in the G - code. It selectively sinters the powder in the areas corresponding to the cross - section of the 3D model. The laser's power, scanning speed, and beam diameter are carefully adjusted based on the material and the desired properties of the printed part. For example, a higher laser power might be used for materials that are more difficult to sinter, while a slower scanning speed can result in a more densely sintered layer.

- Layer by Layer Building: After the laser has sintered the first layer, the build platform is lowered by the thickness of one layer (e.g., 0.1 mm). The powder - spreading mechanism then spreads another layer of powder on top of the previously sintered layer, and the laser scans again to sinter the new layer and bond it to the underlying layer. This process repeats layer by layer until the entire 3D object is completed.

- Post - Processing:

- Once the printing is finished, the 3D object is still embedded in the unsintered powder. The first step in post - processing is to remove the excess powder. This can be done using compressed air or by gently brushing off the powder.

- Depending on the application, further post - processing steps might be required. These can include heat - treating the part to improve its mechanical properties, such as increasing its strength and reducing internal stresses. Surface finishing techniques like sandblasting, vapor smoothing, or painting can also be applied to improve the surface quality and appearance of the printed object. For example, vapor smoothing can significantly reduce the rough, granular surface texture characteristic of SLS - printed parts, making them smoother and more suitable for applications where aesthetics are important.

Comparison with Other 3D Printing Technologies

Comparison with FDM

Fused Deposition Modeling (FDM) is another popular 3D printing technology. Here is a comparison between SLS and FDM in several aspects:

| Aspect | SLS | FDM |

| Materials | Can use a wide variety including polymers (e.g., nylon), metals, ceramics, composites. | Mainly uses thermoplastic filaments like ABS, PLA, PETG. |

| Precision | Generally has a precision of ±0.2mm, suitable for many industrial applications. | Precision is usually lower, around ±0.3 - 0.5mm in consumer - grade printers, which may not be sufficient for high - precision requirements. |

| Speed | Printing speed can be relatively slow due to the sintering process and the need for pre - heating and post - cooling. For example, a medium - sized part may take 10 - 20 hours. | Faster in some cases, especially for simple geometries. A small FDM - printed part can be completed within a few hours. |

| Cost | High initial investment in equipment due to the need for a high - power laser and complex powder - handling systems. Material costs can also be high, but material utilization is good. | Lower equipment cost, especially for consumer - grade models. Material costs are relatively low, but the quality of the final product may not be as high as SLS. |

| Surface Quality | The surface of SLS - printed parts is granular, which may require post - processing for smooth surfaces. | FDM - printed parts have a visible layer - by - layer texture, and the surface finish is often rough without post - processing. |

| Support Structure | No support structure is needed as the unsintered powder supports overhangs. | Support structures are often required for overhanging parts, and removing them can be time - consuming and may damage the part. |

Yigu Technology's View

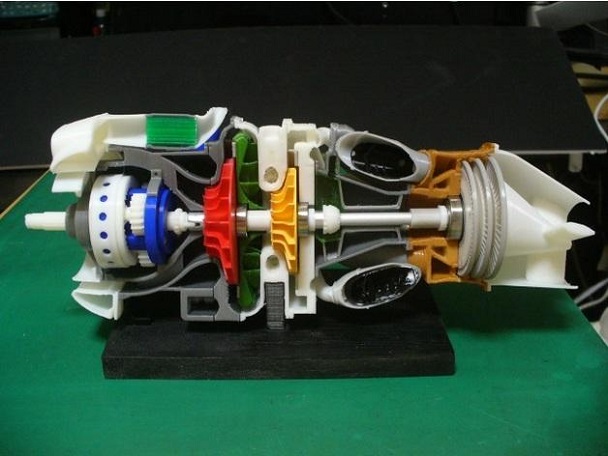

As a non - standard plastic metal products custom supplier, Yigu Technology highly values SLS 3D printing technology. This technology has brought remarkable benefits to product customization. For complex - structured products that are difficult to manufacture through traditional methods, SLS 3D printing can turn them into reality with ease. For example, when creating custom - designed plastic components with intricate internal cavities or undercuts, SLS technology eliminates the need for complex molds and support structures, reducing production time and cost.

In practical applications, Yigu Technology has found that SLS 3D printing offers great flexibility in material selection, allowing us to meet different performance requirements of products. However, challenges also exist. The high cost of equipment and materials is a major factor to consider. Additionally, post - processing to achieve the desired surface quality and mechanical properties requires careful attention and professional techniques. But overall, with continuous technological advancements, SLS 3D printing technology is expected to play an even more significant role in the customization of non - standard plastic metal products.

FAQ

What types of materials can be used in SLS 3D printing?

SLS 3D printing can use a wide variety of materials. Common ones include polymers such as nylon (nylon 11, nylon 12), which are popular for their good mechanical properties, toughness, and chemical resistance. Polycarbonate (PC) powder can also be used, offering high strength and heat resistance. Metals like aluminum, titanium, and stainless - steel powders are suitable for SLS printing in the manufacturing of high - performance parts, especially in the aerospace and automotive industries. Ceramics such as zirconia and alumina can be sintered to create parts with high - temperature resistance and wear - resistance properties. Additionally, composite materials made by mixing different powders, like carbon fiber - reinforced polymers, can be used to achieve enhanced strength - to - weight ratios.

Is SLS 3D printing suitable for large - scale production?

SLS 3D printing has both advantages and limitations for large - scale production. On the one hand, it offers design freedom, allowing for the production of complex geometries without the need for expensive molds, which can be cost - effective for small - to - medium - batch production of customized parts. It also has good material utilization as the unsintered powder can be reused. However, in terms of large - scale, high - volume production, there are challenges. The printing speed is relatively slow compared to some traditional manufacturing methods, and the high cost of equipment and materials can increase production costs significantly. For example, a high - end SLS 3D printer can cost hundreds of thousands of dollars, and the price of specialty powders can be quite high. So, SLS 3D printing may not be the best choice for extremely large - scale, high - volume mass production but can be viable for niche, high - value - added large - scale production scenarios.

How to improve the surface quality of SLS 3D printed parts?

There are several ways to improve the surface quality of SLS 3D printed parts. One common method is post - processing. Sandblasting can be used to remove the loose powder particles on the surface and smooth out the rough texture to some extent. Vapor smoothing is another effective technique, especially for polymer - based SLS parts. In vapor smoothing, the printed part is exposed to a solvent vapor, which melts the surface layer slightly, filling in the gaps between the sintered particles and resulting in a smoother surface. Chemical treatment can also be applied to modify the surface properties and improve smoothness. Additionally, optimizing the printing parameters during the SLS process, such as adjusting the laser power, scanning speed, and powder layer thickness, can help to reduce surface roughness in the first place.