What are 3D Printed Jigs and Fixtures?

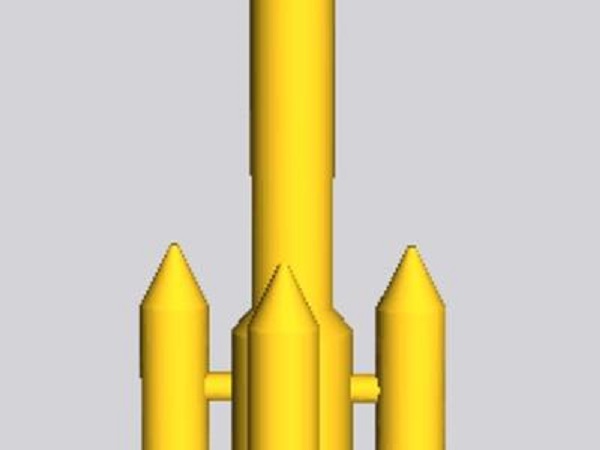

3D printed jigs and fixtures are specialized tools used in manufacturing processes. Jigs are devices that hold, support, and locate the workpiece while guiding the cutting tool, ensuring accurate and consistent machining operations. Fixtures, on the other hand, are mainly used to hold and support the workpiece firmly in place during operations such as machining, welding, or assembly. They are designed to provide stability and repeatability, reducing the risk of errors and improving the overall quality of the manufactured parts.

For example, in a CNC machining process, a 3D printed jig can be used to precisely position a small component for drilling operations. The jig will have holes or slots that match the dimensions of the component, guiding the drill bit to create holes in the exact locations required. A fixture might be used in an automotive assembly line to hold a large metal panel in place while robots weld various parts onto it. This ensures that the panel remains in the correct position throughout the welding process, resulting in a high - quality, consistent product.

Applications of 3D Printed Jigs and Fixtures

Automotive Industry

In the automotive industry, 3D printed jigs and fixtures play a crucial role. For example, in the production of engine components, 3D printed jigs are used to precisely position parts during machining. This ensures that holes are drilled and surfaces are milled to the exact specifications, reducing the tolerance errors. In the assembly line, fixtures hold various parts in place, such as the chassis components during the welding process. A major automotive manufacturer reported that after adopting 3D printed fixtures, the assembly time for a particular model was reduced by 20%, and the defect rate decreased from 5% to 2%. This not only improves production efficiency but also enhances the overall quality of the vehicles, leading to fewer recalls and higher customer satisfaction.

Aerospace Industry

The aerospace industry has extremely high requirements for precision and quality. 3D printed jigs and fixtures are essential for manufacturing high - precision components like turbine blades. These parts need to be produced with micron - level accuracy. 3D printing allows for the creation of complex - shaped jigs that can hold the irregularly shaped turbine blades firmly during the manufacturing process. For instance, the production of a new type of aircraft wing component required a special fixture to support its unique curved shape during machining. A 3D printed fixture was designed and produced in a short time, which not only met the high - precision requirements but also saved significant time compared to traditional fixture manufacturing methods. This enabled the aerospace company to accelerate the development and production of new aircraft models, keeping them competitive in the global market.

Electronics Manufacturing

With the continuous miniaturization and precision of electronic products, 3D printed jigs and fixtures are becoming increasingly important. In the production of printed circuit boards (PCBs), 3D printed jigs can accurately position tiny components during soldering. For example, when mounting surface - mount devices (SMDs) that are only a few millimeters in size, the 3D printed jig ensures that each component is placed in the correct position, reducing the risk of misalignment and solder bridging. In the manufacturing of smartphones, 3D printed fixtures are used to hold the delicate internal components during assembly, protecting them from damage and ensuring a seamless fit. This has led to higher - quality electronic products with fewer malfunctions, improving the user experience and the brand reputation of electronics manufacturers.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the role of 3D printed jigs and fixtures in customized production. We understand that every customer has unique manufacturing needs, and 3D printed jigs and fixtures offer the flexibility and precision required to meet these demands.

In terms of material selection, we have an extensive range of high - quality plastics and metals at our disposal. For plastic - based 3D printed jigs and fixtures, materials like ABS, PLA, and nylon can be chosen according to the specific requirements such as strength, heat resistance, and chemical resistance. For metal 3D printing, materials like aluminum alloys and stainless steels are available, which are suitable for applications that demand high - strength and durability.

Our design team is proficient in using advanced 3D design software. They can collaborate closely with customers to create optimized jig and fixture designs. Whether it's a complex aerospace - related fixture or a precise electronic - manufacturing jig, we ensure that the design maximizes functionality while minimizing material usage and production time. This not only helps our customers save costs but also speeds up their production processes. With our technical expertise and commitment to quality, we are confident in providing top - notch 3D printed jigs and fixtures solutions that meet and exceed our customers' expectations.

FAQ

What materials are commonly used for 3D printed jigs and fixtures?

Common materials for 3D printed jigs and fixtures include plastics like ABS, PLA, and nylon. ABS offers good strength and heat resistance, making it suitable for general - purpose applications in automotive and electronics manufacturing where it can withstand normal operating temperatures. PLA is a more eco - friendly option, often used in less demanding scenarios like small - scale prototyping or in educational settings due to its ease of printing. Nylon has high tensile strength and flexibility, ideal for fixtures that need to grip or hold components firmly. For applications that require higher strength and heat resistance, metals such as aluminum alloys and stainless steels can be used in metal 3D printing. Aluminum alloys are lightweight yet strong, suitable for aerospace applications, while stainless steels offer excellent corrosion resistance and durability for industrial use.

How accurate are 3D printed jigs and fixtures?

The accuracy of 3D printed jigs and fixtures can vary depending on the 3D printing technology used. In general, desktop FDM (Fused Deposition Modeling) printers can achieve an accuracy of around ±0.1 - 0.4 mm. High - end industrial 3D printers, such as SLA (Stereolithography) and SLS (Selective Laser Sintering) printers, can reach much higher accuracies, often in the range of ±0.05 - 0.1 mm. Factors that affect accuracy include the quality of the 3D printer, the complexity of the design, the type of material used, and the post - processing steps. For example, shrinkage during cooling can cause dimensional changes, especially in plastic 3D printing. Post - processing like sanding, polishing, or machining can further improve the accuracy and surface finish of the 3D printed jigs and fixtures.

Can 3D printed jigs and fixtures be used for high - volume production?

3D printed jigs and fixtures can be used for high - volume production, but there are pros and cons. The main advantage is the ability to quickly design and produce custom jigs and fixtures, which can save significant time in the setup phase of high - volume production lines. They can also be optimized for specific production needs, reducing errors and improving efficiency. However, there are potential issues. The production speed of 3D printing may be slower compared to traditional manufacturing methods for high - volume output. Also, the cost per unit may be higher for 3D printed jigs and fixtures, especially if expensive materials or high - end printers are used. To mitigate these issues, some manufacturers use a combination of 3D printing for prototyping and initial setup, and then switch to more cost - effective traditional manufacturing methods for mass production of the jigs and fixtures once the design is finalized.