1. Introduction

1.1 What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three - dimensional solid objects from a digital file. It works on the principle of continuous physical layer - by - layer addition. In traditional manufacturing, material is often removed (subtractive manufacturing) or reshaped (formative manufacturing). But with 3D printing, the object is built up, layer upon layer. For example, a 3D printer takes a digital model designed in CAD (Computer - Aided Design) software. Then, it deposits materials such as plastic, metal powder, or resin in precise geometric shapes. Each layer is like a thinly sliced cross - section of the final object, and as these layers stack up, the 3D object gradually takes shape. This technology has opened up new possibilities in various industries due to its ability to produce complex geometries that were previously difficult or impossible to achieve with traditional methods.

1.2 The Popularity of 3D Printing in China

In recent years, 3D printing has witnessed remarkable growth in China. The market size of 3D printing in China has been expanding steadily. According to relevant reports, the 3D printing market in China reached a value of over 2.5 billion yuan in 2020, and it is expected to grow at an annual compound growth rate of more than 20% in the following years. This growth can be attributed to several factors. Firstly, the Chinese government has been actively promoting the development of high - tech industries, including 3D printing, through various policies and financial support. Secondly, industries such as aerospace, automotive, healthcare, and consumer electronics in China have increasingly recognized the advantages of 3D printing. For example, in the aerospace industry, 3D printing is used to manufacture lightweight and complex - shaped components, which can improve the performance of aircraft while reducing weight and cost. In healthcare, 3D - printed prosthetics and dental implants are becoming more common, providing more personalized and cost - effective solutions for patients. The growing number of 3D printing service providers and research institutions in China also indicates the rising popularity of this technology. From large - scale industrial applications to small - scale creative studios, 3D printing is being widely adopted across different sectors, making it an essential part of the modern manufacturing and innovation ecosystem in China.

2. Advantages of China 3D Printing Service

2.1 Cost - effectiveness

One of the most significant advantages of China 3D printing service is its cost - effectiveness. In comparison with some Western countries, the cost of 3D printing in China is relatively lower. For example, take a look at the following table:

| Cost Items | China | Western Country (e.g., the US) |

| 3D Printer (Industrial - grade) | About \(50,000 - \)200,000 | About \(100,000 - \)500,000 |

| 3D Printing Materials (per kg, PLA) | About \(20 - \)50 | About \(50 - \)100 |

| Labor Cost per Hour | About \(5 - \)15 | About \(20 - \)50 |

The lower cost in China can be attributed to several factors. The large - scale production of 3D printers and printing materials in China reduces the unit cost. Also, the relatively lower labor cost in the manufacturing process contributes to the overall cost - advantage. This cost - effectiveness allows businesses, especially small and medium - sized enterprises, to access high - quality 3D printing services without a large financial burden.

2.2 High - quality Output

China has made remarkable achievements in the quality of 3D printing output. In terms of precision, many Chinese 3D printers can achieve an accuracy of up to 0.01 - 0.1mm, which is on par with international advanced levels. For the surface quality, through advanced post - processing techniques such as polishing and coating, the surface roughness of 3D - printed parts can be significantly reduced, meeting the high - standard requirements of various industries.

In the aerospace industry, China has used 3D printing to manufacture complex - shaped components for aircraft engines and rocket parts. For example, some engine combustion chambers printed by 3D technology have a more precise internal structure, which can improve combustion efficiency and engine performance. In the medical field, 3D - printed dental implants and prosthetics in China not only fit the patient's body structure accurately but also have excellent biocompatibility, providing patients with better treatment experiences.

2.3 Diverse Material Options

China's 3D printing services offer a wide range of material options. Here are some common ones:

- Plastics: Such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and nylon. PLA is biodegradable and suitable for applications like consumer product prototypes and educational models. ABS has high strength and heat resistance, making it ideal for automotive and electronic product parts. Nylon is often used in the production of functional parts that require wear resistance, such as gears.

- Metals: Including aluminum alloy, titanium alloy, and stainless steel. Aluminum alloy is lightweight and has good thermal conductivity, suitable for aerospace and automotive parts to achieve weight reduction. Titanium alloy is known for its high strength - to - weight ratio and excellent corrosion resistance, commonly used in medical implants and high - end aerospace components. Stainless steel is used in manufacturing parts that require high strength and corrosion resistance, like industrial machinery parts.

- Ceramics: Materials like alumina ceramics and zirconia ceramics are used in 3D printing. They have high hardness, wear resistance, and high - temperature resistance, making them suitable for applications in the electronics industry (e.g., electronic substrates) and aerospace (e.g., thermal protection components).

2.4 Fast Turnaround Time

China's 3D printing services also have an edge in terms of production cycle. According to a case study, a small - batch production of 100 customized parts that would take about 15 - 20 days using traditional manufacturing methods only took 3 - 5 days with 3D printing in a Chinese factory. In another example, for the development of a new product prototype, the traditional process, which involves mold design, production, and testing, could take months. However, with 3D printing, the prototype can be completed in a matter of weeks. This fast turnaround time allows companies to accelerate their product development cycles, respond more quickly to market changes, and gain a competitive edge in the market.

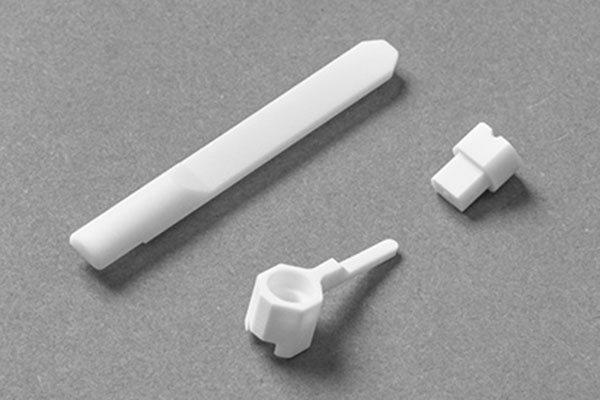

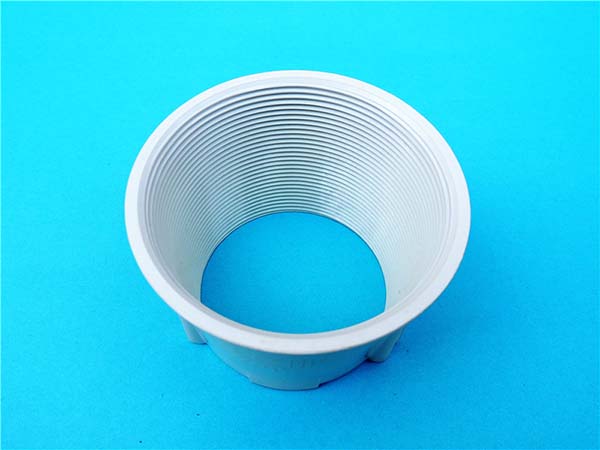

4. Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the role of China 3D printing service. We believe that China's 3D printing service has unique advantages in the production of complex - structured plastic products and metal products. For non - standard plastic products, 3D printing can precisely create intricate shapes, meeting the diverse customized needs of different industries. In terms of metal products, it can produce high - quality components with complex internal structures, which is difficult to achieve through traditional manufacturing methods.

This technology not only satisfies our customers' customized product requirements but also promotes innovation within our company. We are willing to strengthen cooperation with 3D printing service providers in China to jointly explore more application scenarios and bring more high - quality customized products to the market.

5. FAQ

5.1 What materials can be used for 3D printing in China?

In China, a wide variety of materials can be used for 3D printing. For plastics, PLA (Polylactic Acid) is popular due to its biodegradability, often used in consumer product prototypes and educational models. ABS (Acrylonitrile Butadiene Styrene) is another common plastic, known for its high strength and heat resistance, suitable for automotive and electronic parts. When it comes to metals, aluminum alloy, which is lightweight with good thermal conductivity, is used in aerospace and automotive industries to reduce weight. Titanium alloy, with its high strength - to - weight ratio and excellent corrosion resistance, is applied in medical implants and high - end aerospace components. Stainless steel is used for manufacturing parts that require high strength and corrosion resistance, like industrial machinery parts. Additionally, materials such as ceramics (e.g., alumina ceramics and zirconia ceramics) and resins are also widely used in 3D printing, each with their own unique properties and applications.

5.2 How long does it usually take to complete a 3D printing project in China?

The time required to complete a 3D printing project in China varies depending on several factors. For small - scale projects with relatively simple models, it usually takes 3 - 7 days. This includes the time for design review, material preparation, and the actual printing process. For larger and more complex projects, such as manufacturing large - scale industrial parts or complex architectural models, it may take 2 - 4 weeks. The complexity of the model, its size, and the type of material used all influence the production time. For example, a large - sized metal part with intricate internal structures will take longer to print compared to a small plastic prototype.

5.3 What is the accuracy level of 3D printing services in China?

The accuracy level of 3D printing services in China is quite high. Generally, the accuracy can reach 0.1 - 0.2mm in most common 3D printing applications. However, for high - precision 3D printing equipment and advanced manufacturing processes, the accuracy can be even better, reaching below 0.05mm. Different 3D printing technologies and equipment have different levels of accuracy. For instance, some high - end SLA (Stereolithography Apparatus) and DLP (Digital Light Processing) 3D printers, which use light - curing technology, can achieve very high precision, while FDM (Fused Deposition Modeling) printers, although more common and cost - effective, usually have a relatively lower but still acceptable accuracy level within the general range mentioned above.