How do machined prototypes empower industrial innovation?

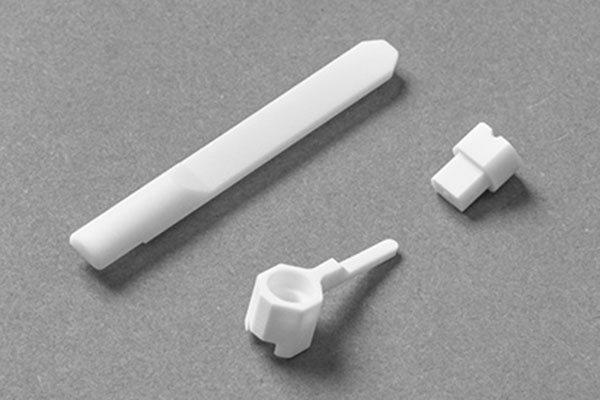

As a key link in product development and industrial manufacturing, machined prototypes(machined prototype) has always been the core bridge connecting the design concept and mass production. Whether it's high-precision components in aerospace or precision structures in medical devices, high-quality machined prototypes can help companies quickly verify designs, optimize processes, and reduce mass production risks. However, in the […]