How Is Direct Rapid Tooling Shaping Innovation

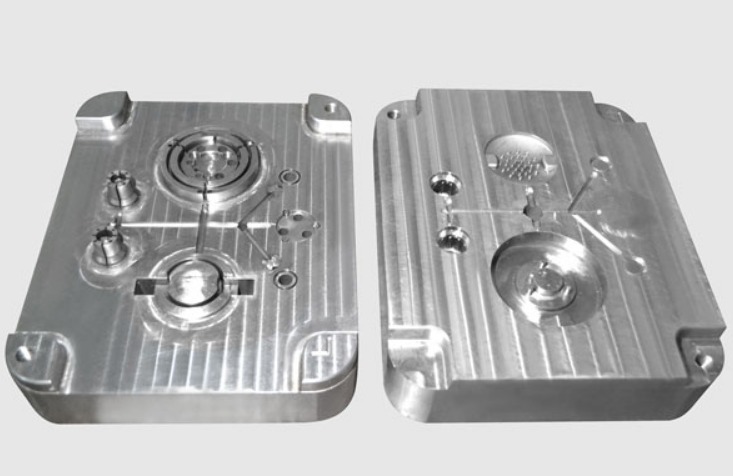

Introduction Definition and Basics of Direct Rapid Tooling Direct Rapid Tooling, often abbreviated as DRT, is a revolutionary approach within the realm of manufacturing. It harnesses the power of Rapid Prototyping (RP) technologies to directly fabricate molds and tooling components. This process circumvents many of the traditional, time - consuming steps involved in tooling production. […]