Introduction

In the dynamic landscape of modern manufacturing, the demand for flexibility and rapid production has become more crucial than ever. This is where Rubber Rapid Prototyping steps in as a game - changer, revolutionizing the realm of flexible manufacturing.

Flexible manufacturing is all about the ability to quickly adapt to changes in product design, production volume, and customer demands. It's the key to staying competitive in a market that is constantly evolving. And rubber, with its unique properties of flexibility, durability, and resistance, has long been a material of choice in many industries, from automotive to consumer goods.

Rubber Rapid Prototyping allows for the fast creation of rubber - based prototypes and end - use parts. It bridges the gap between traditional manufacturing methods, which can be time - consuming and costly, and the need for quick turnarounds in product development. By leveraging advanced technologies, it enables manufacturers to test concepts, make design improvements, and move towards production in a fraction of the time it would take with conventional processes.

What is Rubber Rapid Prototyping

Definition and Basics

Rubber Rapid Prototyping is a cutting - edge manufacturing approach that enables the swift creation of rubber - based prototypes or end - use parts. At its core, it starts with a Computer - Aided Design (CAD) model. This digital representation serves as the blueprint for the entire process. Through a series of precise and automated techniques, the CAD model is translated into a physical rubber object.

The process involves taking the three - dimensional CAD model and slicing it into numerous thin cross - sectional layers. Each layer is then fabricated and stacked upon the previous one, gradually building up the final three - dimensional shape. This layer - by - layer construction method is what differentiates rapid prototyping from traditional subtractive manufacturing processes, where material is removed from a larger block to achieve the desired shape.

Key Technologies Involved

- 3D Printing: One of the most prominent technologies in rubber rapid prototyping is 3D printing, also known as additive manufacturing. There are several 3D printing techniques suitable for rubber materials:

- Stereolithography (SLA): Although SLA is more commonly associated with resin - based materials, advancements have allowed for the use of rubber - like photopolymers. In SLA, a UV laser is used to selectively cure liquid resin in a vat, layer by layer. For rubber SLA, specialized rubber - like resins are developed to have the desired flexibility, durability, and other rubber - specific properties. This technique can achieve high levels of detail, with layer thicknesses as small as 25 - 100 microns, making it suitable for creating complex rubber parts with fine features.

- Fused Deposition Modeling (FDM): FDM can also be adapted for rubber prototyping. Instead of using traditional plastic filaments, rubber - like filaments are extruded through a heated nozzle. The nozzle moves in a predefined path, depositing the molten rubber material layer by layer. FDM - based rubber rapid prototyping is relatively cost - effective and accessible, with the ability to create parts of various sizes. However, the surface finish may not be as smooth as SLA, and the achievable detail is somewhat limited compared to SLA, typically with layer thicknesses ranging from 0.1 - 0.4 mm.

- Selective Laser Sintering (SLS): SLS uses a high - power laser to sinter powdered rubber material. The laser selectively fuses the powder particles together, layer by layer, to form the final part. SLS is advantageous as it can produce parts with good mechanical properties and high accuracy. It can handle a wider range of rubber - like materials and is suitable for creating functional prototypes and end - use parts. The layer thickness in SLS for rubber can be around 0.05 - 0.15 mm.

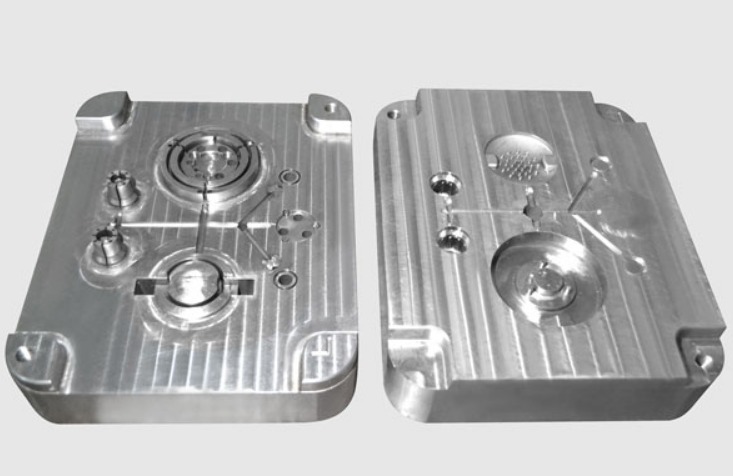

- Injection Molding - based Rapid Prototyping: This involves creating a mold cavity based on the CAD model, often using rapid tooling techniques. Then, liquid rubber is injected into the mold under high pressure. The rubber cures and takes the shape of the mold cavity. This method can produce high - quality rubber parts with good surface finish and dimensional accuracy. However, the mold - making process can still be time - consuming and costly compared to some 3D printing methods, but it is more suitable for producing multiple identical parts in a relatively short time once the mold is ready. For Yigu Technology example, soft silicone rubber parts can be efficiently produced using injection - molding - based rapid prototyping for applications like seals and gaskets.

Rubber Rapid Prototyping vs Other Manufacturing Methods

Comparison Table

When considering manufacturing methods for rubber - based parts, it's essential to compare Rubber Rapid Prototyping with traditional methods. Here is a comparison table highlighting the differences in key aspects such as cost, speed, precision, and complexity handling:

| Aspect | Rubber Rapid Prototyping | Traditional Injection Molding | CNC Machining |

| Cost (Low - Volume Production) | Low - tooling costs, cost - effective for small batches. Material costs can vary depending on the type of rubber used. For example, for a batch of 10 - 50 parts, the cost per part might be around \(20 - \)50 depending on complexity. | High initial tooling costs. The cost of creating a mold can range from \(5,000 - \)50,000 depending on the complexity of the part. For small batches, the cost per part is extremely high. | High - machine setup and labor costs. Machining time can be long, especially for complex parts. For a small batch of 10 - 50 parts, the cost per part could be \(50 - \)100 or more. |

| Cost (High - Volume Production) | As volume increases, the cost per part may not decrease significantly due to the nature of the rapid prototyping process. However, it can still be competitive for some applications. | Cost - effective for high - volume production. As the number of parts increases, the high initial tooling cost is spread out, reducing the cost per part. For example, for 10,000 parts, the cost per part can be as low as \(5 - \)15. | High - volume production costs can be high due to continuous machining time and potential need for multiple setups. The cost per part may not drop as much as injection molding for very high volumes. |

| Speed | Fast turnaround. A simple rubber prototype can be produced in a few hours to a day, depending on the complexity and the 3D printing or rapid tooling method used. | Long lead - time. The mold - making process can take weeks to months, depending on the complexity of the mold. Once the mold is ready, the injection molding process itself can be relatively fast for producing parts. | Moderate speed. Machining time depends on the complexity of the part. A simple part might take a few hours, but a complex part could take days. |

| Precision | High precision is achievable, especially with advanced 3D printing techniques. For example, SLA can achieve tolerances of ±0.1 - 0.2 mm for rubber - like parts. | High precision, with tight tolerances. Modern injection molding machines can achieve tolerances of ±0.05 - 0.1 mm for well - designed molds. | High precision. CNC machines can achieve very tight tolerances, often ±0.01 - 0.05 mm, depending on the machine and the machining process. |

| Complexity of Parts | Excellent for complex geometries. Can easily create parts with undercuts, internal channels, and complex shapes without the need for complex molds or multiple machining operations. | Challenging for extremely complex parts. While complex molds can be made, they are very expensive and time - consuming to produce. Some complex features may require additional manufacturing steps. | Can handle complex parts, but it may require multiple setups and long machining times. Complex geometries may also increase the risk of errors. |

In - Depth Analysis of Differences

- Cost Differences: The low - cost advantage of Rubber Rapid Prototyping in low - volume production is mainly due to the absence of expensive mold - making processes required in traditional injection molding. In injection molding, the high cost of mold creation is a significant barrier for small - scale production. CNC machining's high costs in low - volume production are attributed to the need for skilled labor, machine setup time, and the relatively slow machining process. In high - volume production, injection molding's cost - effectiveness comes from spreading the fixed mold cost over a large number of parts.

- Speed Differences: Rubber Rapid Prototyping is fast because it can directly translate a digital model into a physical part without the need for extensive tooling preparation. Traditional injection molding's long lead - time is mainly due to the mold - making phase, which involves design, machining, and testing of the mold. CNC machining speed depends on the complexity of the part, as more complex parts require more machining operations and longer tool paths.

- Precision Differences: All three methods can achieve high precision, but the nature of the processes affects the achievable tolerances. Rubber Rapid Prototyping techniques like SLA use digital control and precise laser or extrusion mechanisms to build parts layer by layer, enabling good precision. Injection molding's precision is a result of the high - pressure injection of molten rubber into a precisely machined mold. CNC machining's high precision comes from the accurate control of the cutting tools by computer - controlled motors.

- Complexity Handling Differences: Rubber Rapid Prototyping's ability to handle complex geometries easily is a result of its additive manufacturing nature. It can build parts layer by layer, creating features that would be difficult or impossible to achieve with traditional subtractive methods. Traditional injection molding struggles with complex parts because creating molds for such parts is technically challenging and costly. CNC machining can handle complex parts, but it may require multiple setups and more complex machining strategies, increasing the risk of errors and production time.

In summary, Rubber Rapid Prototyping offers unique advantages in terms of cost - effectiveness for low - volume production, speed, and handling of complex geometries, making it a revolutionary approach in flexible manufacturing.

Real - World Applications

Automotive Industry

In the automotive industry, rubber rapid prototyping has found extensive applications. For instance, in the production of cars, rubber rapid prototyping is used to manufacture sealing parts and shock - absorbing pads.

Sealing parts, such as door and window seals, play a crucial role in ensuring the vehicle's interior is free from dust, water, and noise. By using rubber rapid prototyping, automotive manufacturers can quickly produce high - quality seals that precisely fit the complex shapes of car doors and windows. A study shows that compared to traditional manufacturing methods, rubber rapid prototyping can reduce the development time of sealing parts by up to 60%. This allows car manufacturers to quickly adapt to design changes in new car models. In 2022, the global market for automotive rubber sealing parts was valued at approximately $137.2 billion, and this number is expected to grow steadily as more manufacturers adopt rapid prototyping technologies.

Shock - absorbing pads, usually placed in the suspension system and engine mounts, are essential for a smooth and quiet ride. Rubber rapid prototyping enables the production of shock - absorbing pads with customized hardness and damping properties. These pads can effectively reduce vibrations from the road surface and engine operation, improving the overall driving comfort. In terms of cost, for small - scale production runs of shock - absorbing pads (less than 100 units), rubber rapid prototyping can be up to 30% more cost - effective than traditional injection molding, as it eliminates the need for expensive mold - making.

Healthcare Sector

The healthcare sector also benefits greatly from rubber rapid prototyping. In the field of prosthetics, it allows for the creation of customized rubber components. Each patient has unique limb shapes and movement patterns, and rubber rapid prototyping can produce prosthetic sockets and liners that fit perfectly to the patient's residual limb. This not only improves the comfort of the prosthesis but also enhances its functionality. For Yigu Technology example, a patient with an amputated limb may require a prosthetic socket that provides a secure and comfortable fit. Rubber rapid prototyping can create a socket in a matter of days, compared to weeks with traditional methods, enabling the patient to start rehabilitation earlier.

In the production of medical device accessories, rubber rapid prototyping is equally important. Seals in syringes, breathing masks, and catheter components need to be highly reliable to ensure the safety and effectiveness of medical treatments. Rubber rapid prototyping can produce these accessories with high precision and excellent sealing properties. For instance, in the manufacturing of breathing masks for patients with respiratory problems, the rubber seals produced through rapid prototyping can ensure a tight fit on the patient's face, preventing air leakage and ensuring the proper delivery of oxygen or other medical gases.

Consumer Goods

In the consumer goods industry, rubber rapid prototyping has become a powerful tool for innovation. In the production of consumer electronics, such as smartphones and tablets, rubber components like protective cases, anti - slip pads, and shock - absorbing bumpers are commonly produced using rapid prototyping. A major electronics company was able to reduce the time from concept to market for a new smartphone model by 2 months by using rubber rapid prototyping for its protective case design. This allowed them to launch the product ahead of their competitors and gain a larger market share.

In the toy industry, rubber rapid prototyping enables the quick production of unique and flexible toys. For Yigu Technology example, rubber - based action figures with soft and bendable parts can be produced rapidly. These toys are more engaging for children as they can be posed in various ways. A toy manufacturer reported a 40% increase in sales of a new line of rubber - based toys that were developed using rapid prototyping, as the toys stood out in the market with their innovative designs and high - quality rubber materials.

Conclusion

In Yigu Technology conclusion, Rubber Rapid Prototyping is truly revolutionizing flexible manufacturing in multiple ways. It has emerged as a powerful solution that addresses the key challenges faced by modern manufacturers in an ever - changing market.

The technologies involved in Rubber Rapid Prototyping, such as 3D printing and injection - molding - based rapid prototyping, have opened up new possibilities for creating rubber - based parts. These technologies offer a high degree of precision, the ability to handle complex geometries, and significantly reduced production times compared to traditional manufacturing methods.

When compared to traditional injection molding and CNC machining, Rubber Rapid Prototyping stands out, especially in low - volume production scenarios. Its low - tooling costs make it an attractive option for small - scale production runs, allowing companies to test the market with new products without the high financial risks associated with traditional manufacturing. The speed advantage of Rubber Rapid Prototyping also enables faster product development cycles, giving businesses a competitive edge in the market.

The real - world applications in the automotive, healthcare, and consumer goods industries further demonstrate the versatility and importance of Rubber Rapid Prototyping. In the automotive industry, it helps in quickly producing sealing parts and shock - absorbing pads, improving vehicle performance and reducing development time. In healthcare, it enables the creation of customized prosthetics and reliable medical device accessories, enhancing patient care. In the consumer goods sector, it drives innovation by allowing for the rapid production of unique and high - quality rubber components.

FAQs

1. What are the main limitations of Rubber Rapid Prototyping?

One of the main limitations is the relatively limited range of rubber - like materials available compared to traditional rubber manufacturing. Additionally, for very high - volume production, the cost per part may not be as low as traditional injection molding. The surface finish of some 3D - printed rubber parts may also require post - processing to meet certain standards.

2. Can Rubber Rapid Prototyping be used for large - scale production?

While it can be used for production, traditional injection molding is often more cost - effective for extremely large - scale production runs. However, Rubber Rapid Prototyping can be competitive for medium - volume production and is highly suitable for small - batch production, especially when design flexibility and quick turnaround times are crucial.

3. How accurate are the rubber parts produced through rapid prototyping?

The accuracy depends on the specific rapid prototyping technology used. For example, SLA can achieve tolerances of ±0.1 - 0.2 mm for rubber - like parts, while modern injection - molding - based rapid prototyping can achieve tight tolerances similar to traditional injection molding, often around ±0.05 - 0.1 mm for well - designed molds. CNC - machining - based rapid prototyping can also achieve high precision, with tolerances as low as ±0.01 - 0.05 mm depending on the machine and process.