Understanding Metal Prototype Manufacturers

In the complex and dynamic world of product development, metal prototype manufacturers play a pivotal role. But what exactly are they, and why are they so crucial?

A metal prototype manufacturer is a specialized entity that creates initial models of products using metal materials. These prototypes serve as the foundation upon which the final product is built. They are not just simple replicas but are designed with precision, taking into account various factors such as functionality, aesthetics, and manufacturability. For instance, when a company plans to launch a new high - performance electronic device, the metal prototype will be designed to house all the internal components perfectly, with the right cutouts for ports, and a sleek exterior that is both appealing and ergonomic.

The importance of metal prototype manufacturers can't be overstated. Firstly, they significantly impact the final product's quality. A well - crafted metal prototype allows manufacturers to test and refine every aspect of the product before mass production. By doing so, potential design flaws can be identified and rectified early on. For example, in the automotive industry, metal prototypes of new car parts are rigorously tested for durability, strength, and fit. According to industry statistics, over 70% of product failures in the market can be traced back to insufficient prototype testing. Metal prototype manufacturers, with their expertise, help reduce this failure rate by providing accurate and reliable prototypes.

Secondly, they influence the product's performance. The choice of metal, the manufacturing process, and the design of the prototype all contribute to how the final product will perform. A metal prototype for an aerospace component, made with high - strength, lightweight metals like titanium, can ensure that the actual part can withstand extreme conditions during flight, such as high - speed air resistance and temperature variations. This not only improves the product's performance but also enhances its safety and reliability.

In essence, metal prototype manufacturers are the unsung heroes of the product development journey, bridging the gap between an idea and a high - quality, high - performing final product.

Key Factors to Consider When Choosing Metal Prototype Manufacturers

Selecting the right metal prototype manufacturer is crucial for the success of your project. Here are some key aspects to take into account:

Experience and Expertise

An experienced metal prototype manufacturer like Yigu Technology has a deep - seated understanding of the industry. With years of operation, Yigu Technology has amassed a wealth of knowledge in handling diverse projects. They have successfully completed numerous projects across various fields such as aerospace, automotive, and electronics. For example, in the aerospace sector, they have produced high - precision metal prototypes for aircraft components, meeting the stringent requirements of the industry in terms of material strength, heat resistance, and dimensional accuracy. Their experienced engineers can handle complex designs and materials, providing valuable insights and solutions during the prototype development process. This expertise reduces the risk of errors and ensures that the final prototype meets or exceeds expectations.

Range of Services

A good metal prototype manufacturer should offer a comprehensive range of services. This includes design assistance, where they can help refine your initial ideas into a more detailed and manufacturable design. For material selection, they should be able to recommend the most suitable metal materials based on your product's requirements, such as aluminum for lightweight applications or stainless steel for high - corrosion resistance. In terms of manufacturing processes, they may provide CNC machining, which is ideal for creating high - precision parts with complex geometries; 3D printing, which allows for rapid prototyping and the production of intricate designs; and metal casting for large - scale or complex - shaped prototypes. For instance, CNC - machined prototypes are known for their tight tolerances, usually within ±0.01mm, while 3D - printed metal prototypes can be produced much faster, sometimes in a matter of hours, compared to traditional methods.

Quality Control

Quality control is a non - negotiable aspect in metal prototype manufacturing. Manufacturers should use advanced detection equipment like coordinate measuring machines (CMMs) to ensure that the dimensions of the prototype are within the specified tolerances. They should also follow strict quality standards, such as ISO 9001, which sets out the criteria for a quality management system. Regular inspections are carried out at every stage of the production process, from raw material inspection to the final product. For example, before starting production, the metal materials are tested for their chemical composition and mechanical properties to ensure they meet the required standards.

Cost - effectiveness

Cost is an important factor, but it should not be the sole determinant. The cost of metal prototype manufacturing consists of several components, including material costs, which can vary greatly depending on the type of metal used (e.g., titanium is much more expensive than aluminum); processing costs, which are influenced by the complexity of the design and the manufacturing process chosen; and overhead costs. A cost - effective manufacturer will optimize the production process to reduce unnecessary expenses without sacrificing quality. For example, they may source materials in bulk to get better prices or use more efficient manufacturing techniques to save on processing time. However, it's important to note that the cheapest option may not always be the best, as low - cost prototypes may have quality issues that could lead to higher costs in the long run.

Delivery Time

Timely delivery is crucial for any project. A delay in receiving the metal prototype can disrupt the entire product development schedule. According to a study, a one - week delay in prototype delivery can lead to a 10 - 15% increase in the overall project cost, considering factors like extended labor costs, missed market opportunities, and potential penalties in contracts. Reputable manufacturers understand this and have efficient production schedules and supply chains in place to ensure that the prototypes are delivered on time. They also communicate effectively with clients, providing regular updates on the production progress so that clients can plan accordingly.

Comparing Leading Metal Prototype Manufacturers

When looking for a metal prototype manufacturer, it can be beneficial to compare several options. Here is a comparison table of some well - known metal prototype manufacturers, including Yigu Technology:

| Manufacturer | Service Range | Price Range | Customer Reviews | Experience in Years |

| Yigu Technology | Design assistance, material selection, CNC machining, 3D printing, metal casting. Serves aerospace, automotive, electronics industries. | Medium - high. Competitive considering quality and service. Custom quotes based on project complexity. | High satisfaction. Praised for precision, on - time delivery, and technical support. Over 90% positive feedback. | 10+ |

| Company A | Focus on 3D printing and basic CNC machining. Mainly for small - scale consumer product prototypes. | Low - medium. Attractive for budget - conscious startups. Fixed - price packages for standard projects. | Mixed. Some complain about limited service scope, while others like the affordability. 70% positive reviews. | 5 |

| Company B | Offers a wide range of services including forging and sheet metal fabrication. Caters to large - scale industrial projects. | High. Due to high - end equipment and large - scale production capabilities. Cost - plus - margin pricing model. | High - end clients are satisfied with the large - scale production quality. 85% positive reviews. | 15+ |

As shown in the table, Yigu Technology stands out with its comprehensive service range, competitive pricing considering the quality, and high customer satisfaction rate. Its long - term experience enables it to handle complex projects across multiple industries. Company A may be a good choice for those with a tight budget and simpler prototype needs, while Company B is more suitable for large - scale industrial projects.

Yigu Technology's Perspective

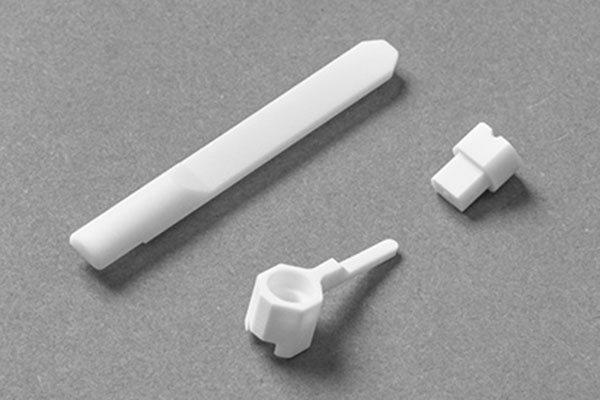

As a non - standard plastic metal products custom supplier, Yigu Technology brings unique strengths to the metal prototype manufacturing field.

In terms of innovative processes, Yigu Technology stays at the forefront of technological advancements. They actively adopt emerging metal processing techniques such as advanced laser - assisted CNC machining. This allows for the creation of prototypes with even more complex geometries and higher precision. For example, in producing prototypes for a new generation of high - end consumer electronics, the laser - assisted CNC machining can achieve ultra - fine surface finishes and extremely tight tolerances, enhancing the overall aesthetics and functionality of the product.

Yigu Technology also prides itself on its rapid response to customer needs. Once they receive a project requirement, their efficient team can quickly mobilize. They can provide preliminary design concepts within 24 hours and start the prototype production within a week, much faster than many competitors. This quick turnaround time ensures that clients can get their prototypes in a timely manner, accelerating their product development cycles.

FAQ

Q1: How can I ensure the quality of metal prototypes?

To ensure the quality of metal prototypes, choose a manufacturer with a comprehensive quality control system. Look for those equipped with advanced detection equipment like CMMs. They should conduct multi - stage quality inspections, starting from raw material testing to final product verification. This way, any potential defects can be identified and corrected promptly.

Q2: What is the typical lead time for metal prototype production?

The lead time varies based on the manufacturing process and the complexity of the prototype. For simple prototypes made through 3D printing, it can take as little as 1 - 3 days. However, more complex prototypes produced by CNC machining or metal casting may require 5 - 15 days or even longer, especially if they involve multiple operations and tight tolerances.

Q3: Can metal prototype manufacturers help with design optimization?

Yes, most professional metal prototype manufacturers, including Yigu Technology, have in - house design teams. They can assist from the initial concept stage, providing valuable suggestions on material selection, manufacturing feasibility, and design optimization. This helps to improve the functionality, manufacturability, and cost - effectiveness of the final product.