The Emergence of Rapid Prototyping

Before the advent of rapid prototyping, traditional manufacturing methods like machining, casting, and molding were the norm. These methods had their merits, but they also came with significant drawbacks, especially when it came to product development. For instance, creating a prototype using traditional casting often required the production of expensive molds. The process was not only time - consuming, taking weeks or even months, but also costly, sometimes running into tens of thousands of dollars, depending on the complexity of the part. This made it a high - risk venture for companies, especially startups with limited budgets and tight time - to - market deadlines.

As the global market became more competitive and consumer demands for new products grew more rapid, the need for a faster and more cost - effective prototyping solution became evident. This necessity birthed rapid prototyping technology, which aimed to revolutionize the product development cycle.

Key Milestones in Rapid Prototyping History

The Early Stage: 1980s - 1990s

The 1980s marked the dawn of rapid prototyping. In 1986, Chuck Hull invented Stereolithography (SLA), the first commercial rapid prototyping technology. SLA used a UV laser to cure liquid photopolymer resin layer by layer, creating a 3D object. The first SLA machine, the SLA - 1 by 3D Systems, could produce parts with a layer thickness of 0.001 - 0.01 inches, which was revolutionary at the time.

The materials used in this early stage were mainly limited to photopolymer resins. These resins were relatively brittle and had limited mechanical properties, but they were sufficient for creating concept models. For example, in product design, designers could quickly create a physical model of a new product concept using SLA, which helped them visualize the design and make improvements faster than traditional methods.

Development in the 2000s

As the new millennium arrived, rapid prototyping technology made significant strides. More materials became available for 3D printing. In addition to various types of plastics like ABS (acrylonitrile - butadiene - styrene) and PLA (polylactic acid), metal powders started to be used in processes such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS).

Equipment also saw remarkable improvements in terms of both speed and accuracy. For instance, SLA machines could now achieve higher build speeds, reducing the production time of a prototype. In the automotive industry, companies like Ford began to use rapid prototyping to create engine components prototypes. These prototypes could be tested for fit and function, saving months in the traditional development cycle. In the aerospace industry, parts such as turbine blades were prototyped using metal - based rapid prototyping techniques, allowing for the exploration of complex geometries that were difficult to achieve with traditional manufacturing methods.

Recent Advancements

In recent years, rapid prototyping has reached new frontiers. Multi - material printing has emerged, enabling the creation of objects with different materials in a single print job. For example, a single 3D - printed part can now have both rigid and flexible sections, opening up new possibilities for product design.

Bioprinting is another exciting development. Scientists are using 3D printers to create tissue - like structures using living cells and biocompatible materials. In the medical field, this has led to the production of patient - specific implants. In architecture, large - scale 3D printers are being used to construct building components, reducing construction time and waste. For example, some companies have successfully 3D - printed entire houses, demonstrating the potential of this technology to revolutionize the construction industry.

Comparison of Different Stages of Rapid Prototyping

To better understand the evolution of rapid prototyping, let's take a look at the comparison of different stages in the following table:

| Stages | Materials | Process | Cost | Precision | Application Areas |

| Early Stage (1980s - 1990s) | Mainly photopolymer resins | Stereolithography (SLA): UV laser cures liquid resin layer by layer | High - equipment cost, relatively high material cost per unit | Layer thickness: 0.001 - 0.01 inches | Product design for concept models |

| Development in the 2000s | Plastics (ABS, PLA), metal powders | Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), improved SLA | Equipment cost reduced over time, material cost varies by type. Metal powder materials are more expensive | Higher precision than early stage, able to meet more functional testing requirements | Automotive (engine components prototypes), aerospace (turbine blades prototypes) |

| Recent Advancements | Multi - materials, living cells and biocompatible materials in bioprinting | Multi - material printing, bioprinting, large - scale 3D printing | Cost still a factor, but economies of scale and new materials are changing the cost structure. Bioprinting materials can be very expensive | High precision in some applications, especially in medical and high - tech fields | Medical (patient - specific implants), architecture (3D - printed building components and houses) |

From this comparison, we can clearly see how rapid prototyping has evolved. The expansion of available materials has enabled the technology to be used in a wider range of applications. The improvement in processes has led to better precision and speed, while cost - effectiveness has also been gradually optimized, making rapid prototyping more accessible to various industries.

Yigu Technology's View

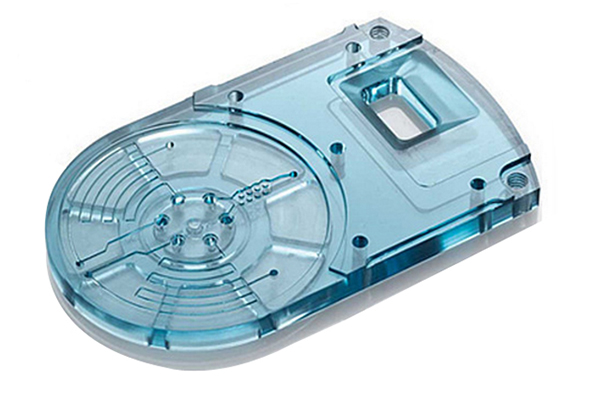

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the historical development of rapid prototyping. This technology has been a game - changer for the industry. It has significantly accelerated product development cycles. In the past, creating custom non - standard parts often took a long time due to the complex traditional manufacturing processes. However, with rapid prototyping, Yigu Technology can quickly transform design concepts into physical prototypes. This not only allows for faster design verification but also enables more efficient communication with clients during the product development phase.

Moreover, rapid prototyping has enabled Yigu Technology to better meet the diverse and customized needs of clients. Different materials and advanced processes in rapid prototyping mean that the company can produce unique parts with complex geometries that were once difficult or costly to manufacture. It has opened up new business opportunities and enhanced the company's competitiveness in the market.