What is Rapid Tooling Solutions?

In the world of manufacturing, Rapid Tooling Solutions has emerged as a game - changer, especially for those new to the field. At its core, rapid tooling is a set of techniques that enable the fast production of molds and tools used in manufacturing processes.

Let's take an example from the automotive industry to make it easier to understand. Suppose a car manufacturer wants to develop a new design for a car's interior door panel. In the past, using traditional tooling methods, the process would be long and complex. First, a detailed design would be created on paper or using CAD (Computer - Aided Design) software. Then, a highly skilled team would start machining a mold from a solid block of metal, such as steel or aluminum. This machining process could take weeks or even months, depending on the complexity of the door panel's shape.

However, with rapid tooling solutions, the scenario is quite different. Using 3D printing technology, which is one of the key components of rapid tooling, the manufacturer can quickly create a prototype of the door panel. The 3D printer reads the CAD design and builds the part layer by layer, usually from a plastic - based material. This prototype can be produced in a matter of days or even hours, depending on its size and complexity.

Once the prototype is ready, it can be tested for fit, function, and aesthetics. If any design flaws are found, the CAD model can be easily modified, and a new prototype can be printed. This iterative process allows for quick design improvements without the need to start from scratch with a new mold, as would be the case in traditional tooling.

In essence, rapid tooling solutions combine advanced technologies like 3D printing, computer - controlled machining, and innovative materials to significantly reduce the time and cost required to produce tools and molds. It provides a more flexible and efficient way to bring new products to the market, whether it's a small - scale production run or the initial stages of product development.

Key Aspects of Rapid Tooling Solutions

1. Process Types

There are two main process types in rapid tooling solutions: direct rapid tooling and indirect rapid tooling.

Direct Rapid Tooling

- Process Steps: In direct rapid tooling, the mold or tool is created directly from the digital design data. For example, in selective laser sintering (SLS) for direct metal tooling, a high - power laser sinters metal powder layer by layer according to the CAD model. Each layer is fused together to form the final tool.

- Materials Used: Metals like stainless steel, aluminum alloys, and some high - temperature - resistant alloys can be used. For instance, in aerospace applications, nickel - based alloys are sometimes used in direct rapid tooling for high - temperature - resistant molds.

- Cost: Generally, the cost of direct rapid tooling can be high, especially when using expensive metals. The equipment for direct metal rapid tooling, such as high - power lasers and specialized sintering machines, is costly, and the cost of raw materials also contributes to the high price. However, for complex geometries that would be extremely expensive to produce through traditional machining, the cost can be competitive.

- Time: The production time can be relatively short, especially for small - scale and complex parts. Since there is no need for intermediate steps like creating a master pattern, the tool can be produced in a matter of hours to a few days, depending on the complexity and size.

- Accuracy: High accuracy can be achieved, often with tolerances in the range of ±0.1 - 0.2 mm, which is sufficient for many high - precision applications.

Indirect Rapid Tooling

- Process Steps: Indirect rapid tooling involves creating a master pattern first, usually through a rapid prototyping method like 3D printing. Then, a mold is made from this master pattern. For example, in the case of silicone rubber molding, a 3D - printed plastic prototype is used as the master pattern. Liquid silicone rubber is poured around the prototype, and after curing, the prototype is removed, leaving a silicone rubber mold.

- Materials Used: Silicone rubber, epoxy resins, and some low - melting - point metals like zinc - aluminum alloys are commonly used. For small - scale product development, silicone rubber is a popular choice due to its flexibility and ease of use.

- Cost: Cost - effective, especially for low - volume production. The materials are generally less expensive than the metals used in direct rapid tooling, and the equipment required for processes like silicone rubber molding is more affordable.

- Time: The overall time can be longer than direct rapid tooling as it involves multiple steps. Creating the master pattern, making the mold, and any post - processing steps can add up to a production time of several days to a week.

- Accuracy: Accuracy is typically good, but may be slightly lower than direct rapid tooling, with tolerances in the range of ±0.2 - 0.5 mm, which is still acceptable for many consumer product and small - batch manufacturing applications.

Here is a comparison table for a clearer understanding:

| Aspect | Direct Rapid Tooling | Indirect Rapid Tooling |

| Process Steps | Create mold/tool directly from digital data | Create master pattern first, then mold from it |

| Materials Used | Stainless steel, aluminum alloys, nickel - based alloys | Silicone rubber, epoxy resins, zinc - aluminum alloys |

| Cost | High (due to equipment and materials) | Low - cost (less expensive materials and equipment) |

| Time | Short (hours - few days for small/complex parts) | Long (several days - week) |

| Accuracy | High (±0.1 - 0.2 mm) | Good (±0.2 - 0.5 mm) |

2. Materials Used

- Silicone Rubber

- Properties: Silicone rubber has excellent flexibility, high heat resistance (it can withstand temperatures up to 200 - 300°C in some cases), and good chemical stability. It also has a very low shrinkage rate, which is crucial for maintaining the accuracy of the mold.

- Suitable Scenarios: Ideal for creating molds for small - scale production of intricate parts, such as in the jewelry industry for casting small metal parts or in the production of soft toys. For example, a jewelry designer can use a silicone rubber mold to cast multiple copies of a unique pendant design.

- Advantages: It is easy to work with, can be poured into complex - shaped master patterns, and the cured rubber has good release properties, making it easy to remove the cast parts. It is also relatively inexpensive compared to many other tooling materials.

- Disadvantages: The mold lifespan is relatively short compared to metal molds. It may degrade over time with repeated use, especially under high - stress or high - temperature conditions.

- Epoxy Resins

- Properties: Epoxy resins offer high strength, good dimensional stability, and excellent adhesion. They can be formulated to have different hardness levels, from relatively soft for certain applications to very hard for more durable molds.

- Suitable Scenarios: Used in the production of molds for medium - scale manufacturing, such as in the production of plastic parts for consumer electronics. For example, an electronics company might use an epoxy resin mold to produce a small batch of custom - designed plastic enclosures.

- Advantages: Cost - effective for medium - volume production, and they can be easily customized by adding fillers or other additives to improve specific properties. They also have good chemical resistance.

- Disadvantages: They are brittle in some formulations, and the curing process can be sensitive to temperature and humidity, which may affect the final quality of the mold.

- Metals (e.g., Aluminum, Steel)

- Properties: Metals have high strength, excellent heat conductivity, and high wear resistance. Aluminum is lightweight and has good corrosion resistance, while steel offers extremely high strength and durability.

- Suitable Scenarios: Ideal for high - volume production and applications where high precision and long - term use are required. For example, in the automotive industry, steel molds are used for stamping large - scale body parts, and aluminum molds are used for die - casting engine components.

- Advantages: Long - lasting, can withstand high - pressure and high - temperature manufacturing processes, and can produce parts with very high accuracy and surface finish.

- Disadvantages: High initial cost, both in terms of the material itself and the equipment required to process it. The manufacturing process can also be time - consuming, especially for complex geometries.

Applications of Rapid Tooling Solutions

1. Automotive Industry

- Component Development: In the automotive industry, rapid tooling plays a crucial role in the development of new components. For example, when developing a new engine cylinder head, traditional tooling methods would require a long time to create a prototype mold. With rapid tooling, a 3D - printed mold can be produced in a short time. This allows automotive engineers to quickly test different design concepts for the cylinder head, such as the shape of the combustion chambers and the layout of the coolant channels. By reducing the time to create prototypes, the overall development cycle of the engine can be significantly shortened, which is essential in a highly competitive automotive market.

- Low - Volume Production: Small - scale automotive manufacturers or those producing limited - edition models benefit greatly from rapid tooling for low - volume production. For instance, a company that specializes in producing custom - built sports cars may need to produce only a few hundred units of a particular body panel. Using traditional high - cost, high - volume production tooling would be economically unfeasible. However, with rapid tooling solutions like silicone rubber molding or direct metal laser sintering (DMLS), they can produce these body panels at a much lower cost per unit. The ability to quickly produce molds also means that they can make design changes for each batch if needed, adding a level of customization that is difficult to achieve with traditional tooling.

- Customization: Rapid tooling enables automotive customization on a whole new level. Car enthusiasts often want to modify their vehicles with unique parts, such as custom - designed grilles, spoilers, or interior trims. A small - scale customization shop can use rapid tooling to create molds for these custom parts. For example, a customer might want a personalized grille for their car. The shop can use 3D scanning technology to create a digital model of the customer's car's front end, design a custom grille in CAD software, and then use rapid tooling to produce a mold for the grille. This allows for a high - level of personalization while keeping the production time and cost reasonable.

2. Consumer Goods

- Electronics: The consumer electronics industry is highly dynamic, with new products being launched constantly. For example, when a smartphone manufacturer wants to release a new model with a unique design for its phone case, rapid tooling can speed up the process. Using 3D printing, they can quickly create a prototype of the new phone case design. Once the design is finalized, they can use indirect rapid tooling methods like silicone rubber molding to produce a small batch of cases for initial market testing. If the market response is positive, they can then scale up production. This reduces the time from concept to market launch, which is crucial in a market where consumers expect the latest technology and design trends.

- Toys: In the toy industry, rapid tooling helps meet the demand for diverse and innovative toys. Toy companies often need to quickly produce new molds for different toy designs, especially during the holiday season when new toys are in high demand. For example, a company that creates action figures can use rapid tooling to produce molds for new character designs in a matter of days. This allows them to respond quickly to popular culture trends. If a new superhero movie is released, they can create and produce action figures of the movie's characters in time for the holiday shopping season, maximizing their sales potential.

3. Medical Devices

- Custom Medical Devices: In the medical field, every patient can be unique, and sometimes custom - made medical devices are required. For example, in the case of prosthetics, rapid tooling allows for the creation of custom - fit prosthetics. A 3D scan of a patient's residual limb can be taken, and a digital model is created. Using rapid tooling, a mold can be quickly produced to manufacture a prosthetic limb that fits the patient perfectly. This not only improves the comfort and functionality of the prosthetic but also reduces the waiting time for the patient to receive their device.

- Rapid Prototyping: When developing new medical devices, such as a new type of surgical instrument, rapid prototyping through rapid tooling is essential. A medical device company can use 3D printing to create a prototype of the surgical instrument. This prototype can then be tested by surgeons in simulated surgical environments. Based on the feedback, the design can be refined, and new prototypes can be quickly produced. This iterative process helps in creating a more effective and user - friendly surgical instrument, which ultimately benefits patients.

Yigu Technology's View

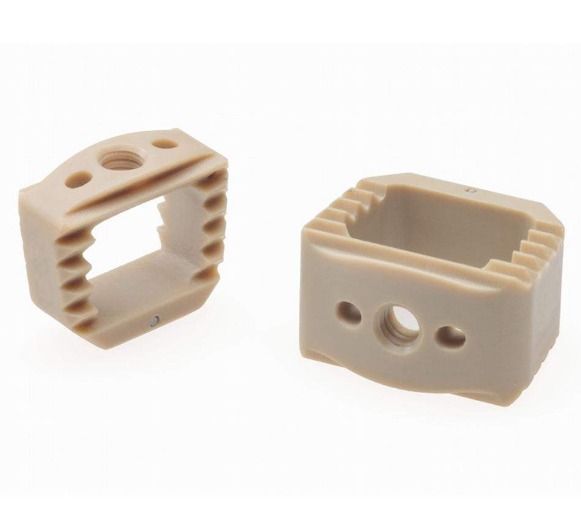

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the significance of Rapid Tooling Solutions. With years of experience in the manufacturing field, we have witnessed how rapid tooling can revolutionize product development and production.

Our team of experts is well - versed in the various rapid tooling processes, allowing us to offer tailored solutions to our clients. Whether it's using 3D printing for quick prototyping or silicone rubber molding for small - batch production, we have the capabilities to meet diverse customer needs.

The advantage of rapid tooling for our clients lies in its ability to significantly reduce time - to - market. In today's highly competitive business environment, being able to quickly iterate on product designs and get products to consumers faster can make a huge difference. Moreover, the cost - effectiveness of rapid tooling, especially for low - volume production, is a major plus. It enables our clients, especially startups and small - to - medium - sized enterprises, to access high - quality tooling solutions without breaking the bank. At Yigu Technology, we are committed to leveraging rapid tooling solutions to help our clients achieve their business goals and drive innovation in their respective industries.

FAQ about Rapid Tooling Solutions

1. What is the difference between direct and indirect rapid tooling?

In direct rapid tooling, the mold or tool is created directly from digital design data, often using technologies like selective laser sintering for metals. It offers high accuracy with tolerances around ±0.1 - 0.2 mm, short production times for small - complex parts, but is costly due to expensive equipment and materials. Indirect rapid tooling, on the other hand, involves creating a master pattern first (e.g., via 3D printing) and then making a mold from it. Materials like silicone rubber or epoxy resins are commonly used. It is more cost - effective, especially for low - volume production, but has a longer production time and slightly lower accuracy, with tolerances in the range of ±0.2 - 0.5 mm.

2. How accurate are the molds produced by rapid tooling?

The accuracy of molds produced by rapid tooling depends on the process and materials used. In direct rapid tooling, especially with advanced metal - based processes, tolerances as low as ±0.1 - 0.2 mm can be achieved. For example, in direct metal laser sintering, the high - precision laser can precisely fuse metal powders to create highly accurate molds. Indirect rapid tooling, such as silicone rubber molding, usually has an accuracy in the range of ±0.2 - 0.5 mm. Factors that can affect accuracy include the quality of the digital model, the stability of the rapid tooling equipment, and the properties of the materials used during the process.

3. Can rapid tooling be used for large - scale production?

Rapid tooling can be used for large - scale production to some extent, but it has limitations. For low - volume to medium - volume production, rapid tooling is quite feasible. For instance, in the production of small - batch consumer goods, the cost - effectiveness and quick production time of rapid tooling make it a great choice. However, for high - volume production, traditional tooling methods may be more suitable. This is because the cost per unit of rapid tooling, especially when using expensive materials in direct rapid tooling, can be high for large quantities. Also, the production speed of rapid tooling may not meet the high - volume demands in a timely manner. But with continuous technological advancements, the feasibility of using rapid tooling for larger - scale production is gradually increasing.