What is Injection Moulding?

Injection moulding is a widely used manufacturing process for producing plastic parts in large quantities. At its core, the process involves injecting molten material, usually plastic, into a mould cavity, where it cools and solidifies into the desired shape. This method is highly efficient and versatile, making it suitable for a wide range of industries, from automotive and aerospace to consumer goods and electronics.

The process begins with the raw plastic material, which is typically in the form of small pellets. These pellets are fed into a heated barrel, where they are melted by a combination of heat and mechanical shear. The molten plastic is then forced, or injected, under high pressure into a closed mould cavity through a sprue, runner system, and gates. Once the mould cavity is filled, the plastic is allowed to cool and solidify. After the plastic has hardened, the mould opens, and the finished part, also known as the "moulding," is ejected.

For example, think about the plastic housing of your smartphone. It's made through injection moulding. The design of the phone's housing is first created in a 3D model. Then, a metal mould is crafted based on this design. Plastic pellets are melted and injected into this mould. After cooling, the precise and complex shape of the phone housing, with all its cutouts for buttons, ports, and speakers, is formed.

The Process Steps in Injection Moulding

Injection moulding is a complex process with several key steps, each of which plays a crucial role in determining the quality and efficiency of the final product. Let's take a closer look at these steps:

Clamping

The first step in the injection moulding process is clamping. This involves closing the mould halves together with a high - force clamping unit. The clamping force is essential to keep the mould closed during the injection and packing phases when high pressures are applied to inject the molten plastic into the mould cavity.

Typical clamping forces can range from a few tons to thousands of tons, depending on the size and complexity of the mould. For example, a small mould for producing simple plastic parts might require a clamping force of 50 - 100 tons, while a large mould for automotive components could need 1000 - 3000 tons or more. If the clamping force is insufficient, the mould may open slightly during injection, leading to flash (excess plastic seeping out between the mould halves), which not only ruins the appearance of the product but also affects its functionality. A well - clamped mould ensures that the plastic is contained within the desired cavity, enabling the creation of accurate and high - quality parts.

Injection

Once the mould is clamped, the injection phase begins. The plastic pellets, which have been heated and melted in the injection unit's barrel, are forced into the mould cavity through a runner system and gates. The injection process is characterized by two key parameters: injection pressure and injection speed.

Injection pressure can vary widely, typically ranging from 50 - 200 MPa (megapascals). High - pressure injection is often used for complex parts with thin walls, as it helps the molten plastic to fill the intricate details of the mould cavity. For instance, in the production of small, high - precision electronic components, injection pressures of 150 - 200 MPa might be required. Injection speed, on the other hand, affects how quickly the plastic fills the cavity. A faster injection speed can reduce the cycle time but may also cause issues such as air entrapment or flow marks on the product surface if not carefully controlled. In general, for parts with large, flat surfaces, a slower injection speed might be preferred to ensure uniform filling and prevent surface defects.

Packing

After the mould cavity is filled with molten plastic during the injection phase, the packing stage commences. The purpose of packing is to compensate for the shrinkage of the plastic as it cools and solidifies. During cooling, most plastics undergo a volumetric contraction, which can lead to voids, sink marks, or dimensional inaccuracies in the final product if not addressed.

To counteract this, additional molten plastic is injected into the cavity at a lower pressure during the packing stage. The packing pressure and time are carefully adjusted based on the type of plastic and the design of the part. For example, for a polyethylene (PE) part, a packing pressure of around 30 - 50 MPa might be used, and the packing time could range from 1 - 5 seconds. Proper packing ensures that the final product has the correct dimensions, a smooth surface finish, and good structural integrity. Without sufficient packing, products may have visible depressions (sink marks) on their surfaces, especially in thick - walled areas, or internal voids that weaken the part.

Cooling

The cooling stage is where the molten plastic in the mould cavity solidifies into the final product shape. This is a critical step as the cooling time and temperature control directly impact both the product quality and the production efficiency.

Cooling time can vary significantly depending on factors such as the thickness of the part, the type of plastic, and the cooling system design. Thicker parts generally require longer cooling times. For a thin - walled plastic cup with a wall thickness of 1 - 2 mm, the cooling time might be only a few seconds, while a thick - walled automotive bumper with a wall thickness of 5 - 10 mm could need 30 - 60 seconds or more to cool properly. The cooling system in an injection moulding machine typically uses circulating water or a heat - transfer fluid to remove heat from the mould. Maintaining a consistent and appropriate cooling temperature is crucial. If the cooling is too rapid, it can cause internal stresses in the plastic, leading to warping or cracking of the product. On the other hand, if the cooling is too slow, it will increase the cycle time and reduce production output.

Ejection

Once the plastic part has cooled and solidified sufficiently, it is ready to be ejected from the mould. Ejection is accomplished using a system of ejector pins, sleeves, or other ejector mechanisms. These components push the part out of the mould cavity when the mould opens.

Care must be taken during the ejection process to avoid damaging the product. The ejector pins should be properly located and sized to distribute the ejection force evenly across the part. If the ejector pins are too small or not placed in the right positions, they can cause marks, dents, or even breakage of the part. For example, in the ejection of a delicate plastic figurine, the ejector pins need to be positioned in areas that are not visible on the final product, such as the base or hidden under appendages, and the force applied should be carefully calibrated to ensure a smooth ejection without any damage to the fine details of the figurine.

Applications of Injection Moulding

Injection moulding's versatility makes it an invaluable manufacturing process across a wide array of industries. Here are some of the key sectors where injection moulding plays a significant role:

Automotive Industry

In the automotive industry, injection moulding is used for a vast number of components. For interior parts, components like dashboards, door panels, and seat trims are often made through injection moulding. Dashboards, in particular, require a high degree of precision to ensure that all the instrument clusters, control panels, and other elements fit together seamlessly. Injection moulding allows for the creation of complex shapes with accurate dimensions, enabling the integration of various functions such as air vents, storage compartments, and wiring channels within a single part.

Exterior components like bumpers, body panels, and spoilers also benefit from injection moulding. Bumpers, for example, need to have a specific shape to provide effective impact absorption while also contributing to the vehicle's aerodynamics and aesthetics. Injection - moulded bumpers can be made from materials such as polypropylene (PP) with rubber additives for enhanced impact resistance. These bumpers can be produced in large quantities with consistent quality, meeting the high - volume production demands of the automotive industry.

Engine components such as intake manifolds are also commonly injection - moulded. Plastic intake manifolds are lighter than their metal counterparts, which helps in reducing the overall weight of the vehicle and improving fuel efficiency. Injection moulding can create the complex internal channels required for the efficient flow of air into the engine cylinders, ensuring optimal engine performance.

Consumer Goods

The consumer goods industry is another major beneficiary of injection moulding. In the electronics sector, injection - moulded plastic is used for the production of device housings, such as those for smartphones, tablets, and laptops. These housings need to be lightweight, durable, and aesthetically pleasing. Injection moulding allows for the use of different types of plastics, such as acrylonitrile butadiene styrene (ABS) or polycarbonate (PC), which can be customized to have specific properties like high impact resistance, good heat dissipation, or a sleek finish.

Toys are also frequently made through injection moulding. The process enables the production of toys with intricate details and bright colors. Manufacturers can produce large numbers of toys quickly and cost - effectively, making them affordable for consumers. For example, plastic action figures, building blocks, and toy cars are all mass - produced using injection moulding.

In the home goods category, items like kitchen utensils, storage containers, and furniture parts are often injection - moulded. Storage containers, for instance, need to have a tight - fitting lid to keep food fresh. Injection moulding can create containers with precise tolerances, ensuring a perfect seal. Furniture parts, such as chair legs or table bases, can be injection - moulded from materials like polypropylene, providing a cost - effective and lightweight alternative to traditional materials like wood or metal.

Medical Field

In the medical field, injection moulding is used to produce a wide range of products. Syringes are a prime example. They require high - precision manufacturing to ensure accurate dosing and safe use. Injection - moulded syringes are made from medical - grade plastics that are biocompatible, meaning they do not cause adverse reactions when in contact with the human body. The process allows for the production of syringes with smooth inner walls to facilitate the easy flow of fluids and sharp, accurate needle tips.

Medical device housings, such as those for diagnostic equipment like ultrasound machines or blood glucose monitors, are also made through injection moulding. These housings need to protect the sensitive internal components from environmental factors and provide a user - friendly interface. Injection - moulded housings can be designed to be lightweight, durable, and easy to clean, meeting the strict hygiene requirements of the medical industry.

Prosthetic components are another area where injection moulding is applied. Parts of artificial limbs, such as sockets or joints, can be injection - moulded to fit the patient's body precisely. The ability to produce custom - designed components through injection moulding, combined with the use of high - strength, lightweight plastics, has greatly improved the functionality and comfort of prosthetics.

Yigu Technology's Perspective

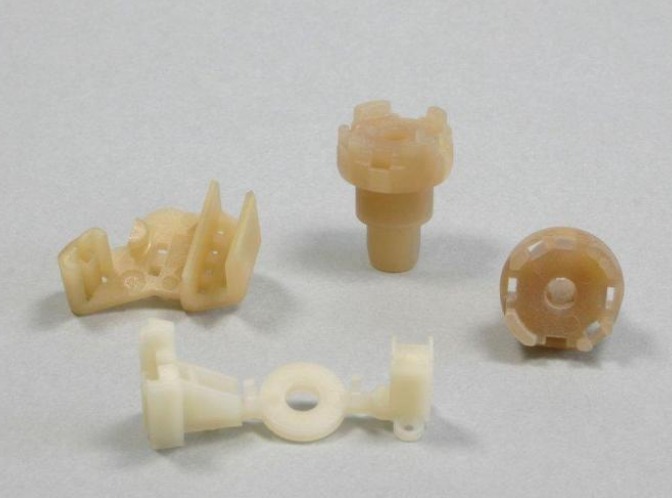

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values injection moulding. Our in - depth understanding of this process allows us to provide customized solutions that meet the unique needs of our clients.

We take pride in our advanced equipment and a team of experienced engineers. This combination enables us to handle complex injection moulding projects with precision. For example, when creating non - standard plastic parts for a client in the electronics industry, our engineers used their expertise to optimize the mould design. By doing so, we not only reduced the production cost but also improved the product quality, ensuring that the parts fit perfectly into the final product.

In terms of service, we offer end - to - end support, from the initial design concept to the final product delivery. We believe that close communication with clients is crucial. Through regular consultations, we can better understand their requirements and make timely adjustments to the injection moulding process.

Looking ahead, we see great potential for the injection moulding industry. With the continuous development of new materials and technologies, we are committed to keeping up with the trends. We aim to explore new applications of injection moulding, such as in the emerging fields of renewable energy and smart devices, to provide more value - added services to our clients.