Introduction to Runner Types in Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. The runner system in injection molding plays a crucial role in determining the quality, cost, and production speed of the final products. It serves as the pathway through which the molten plastic material flows from the injection machine nozzle to the mold cavity. Understanding different runner types is essential for mold designers, engineers, and manufacturers to optimize the injection molding process.

The runner system not only distributes the molten plastic evenly to each cavity but also affects the filling time, pressure drop, and temperature distribution during the injection process. A well - designed runner system can reduce material waste, improve part quality by minimizing defects such as weld lines and air traps, and increase the overall productivity of the injection molding operation. In the following sections, we will explore various runner types in detail, including their characteristics, advantages, and disadvantages.

Types of Runners

Cold Runners

Cold runners are the most traditional type of runner system in injection molding. In a cold runner system, the runner channels are not heated and are cooled along with the molded parts. Once the injection molding cycle is complete, the solidified runner and the parts are ejected together from the mold.

Structure and Working Principle: The cold runner typically consists of a sprue, which is the main channel connecting the injection machine nozzle to the mold, runners that distribute the molten plastic to the cavities, and gate s that control the flow of plastic into each cavity. When the molten plastic is injected into the mold, it flows through these channels. After cooling, the runner and the parts are separated, and the runner material is usually recycled. For example, in a simple two - cavity mold, the sprue feeds the molten plastic into a main runner, which then branches out into two sub - runners, each leading to a cavity.

Applications: Cold runners are widely used in the production of large - scale plastic products where the cost of runner material is relatively low compared to the overall product cost. For instance, in the automotive industry, the production of large plastic bumpers often employs cold runner systems. The runner material can be recycled, and the relatively large size of the parts means that the waste from the runner does not significantly impact the overall cost. In the production of plastic household items like buckets and storage containers, cold runners are also a common choice due to their simplicity and cost - effectiveness for large - volume production.

Hot Runners

Hot runner systems have become increasingly popular in modern injection molding due to their numerous advantages.

Working Mechanism: In a hot runner system, the runner channels are heated to keep the plastic in a molten state throughout the injection molding process. This is achieved by using heaters, such as cartridge heaters or band heaters, which are installed around the runner manifold and nozzles. The molten plastic can be directly injected into the cavities without the need to solidify in the runner. As a result, there is no runner waste to be ejected and recycled, which simplifies the molding process.

Advantages:

- Increased Production Efficiency: Since there is no need to wait for the runner to cool and be ejected, the cycle time of the injection molding process can be significantly reduced. For example, in the production of small, high - volume electronic components, a hot runner system can reduce the cycle time by up to 30%, leading to a substantial increase in production output.

- Cost - Savings: Although the initial investment in a hot runner system is higher than that of a cold runner system, the long - term cost savings are significant. The elimination of runner waste reduces material costs, especially for expensive engineering plastics. Additionally, the reduced cycle time means lower labor costs per part.

- Improved Product Quality: Hot runner systems can provide more consistent filling of the cavities, reducing the occurrence of defects such as weld lines and air traps. This results in higher - quality parts with better surface finish and dimensional accuracy.

Applications: Hot runner systems are commonly used in the injection molding of high - precision and high - value products. In the electronics industry, they are used for manufacturing components such as connectors, where tight tolerances and high - quality finishes are required. The ability to produce parts with fewer defects and greater consistency makes hot runners ideal for such applications.

Insulated Runners

Insulated runner systems are designed to reduce heat loss from the runner channels, allowing the plastic to remain in a semi - molten state without the need for active heating as in hot runner systems.

Principle: Insulated runners use special insulation materials or geometric designs to minimize heat transfer from the molten plastic in the runner to the surrounding mold. For example, some insulated runner systems use air gaps or low - thermal - conductivity materials around the runner channels. By reducing heat loss, the plastic can flow through the runner for multiple injection cycles before solidifying.

Advantages and Disadvantages:

- Advantages: Insulated runners offer a balance between the simplicity of cold runners and the efficiency of hot runners. They can reduce runner waste compared to cold runners since the runner material does not solidify immediately. Additionally, they have a lower initial cost than hot runner systems, making them an attractive option for some manufacturers.

- Disadvantages: However, they are not as effective as hot runners in maintaining the plastic in a fully molten state. There is still some heat loss over time, which can lead to inconsistent flow and potential defects in the molded parts if not properly managed.

Applications: Insulated runners are often used in the production of medium - volume plastic products where cost - effectiveness and some reduction in runner waste are desired. For example, in the production of certain types of plastic toys or small - scale industrial components, insulated runners can be a suitable choice, providing a reasonable compromise between cost and production efficiency.

Comparison of Runner Types

To better understand the differences between cold runners, hot runners, and insulated runners, the following table provides a comparison in terms of cost, production efficiency, product quality, applicable materials, and product types:

| Comparison Items | Cold Runners | Hot Runners | Insulated Runners |

| Cost | - Low initial mold cost. - High material waste, leading to higher long - term material costs as the runner material needs to be recycled. - Low maintenance cost as there are no heating elements. | - High initial investment due to heating elements, temperature control systems, and complex manifolds. - Low material cost as there is no runner waste. - High maintenance cost, including potential replacement of heating elements and regular inspection of the temperature control system. | - Moderate initial cost, lower than hot runners. - Moderate material waste, less than cold runners but more than hot runners. - Low to moderate maintenance cost, mainly related to ensuring the integrity of the insulation. |

| Production Efficiency | - Long cycle time as the runner needs to cool before ejection. - Low - speed production due to the additional time for runner solidification and removal. | - Short cycle time since the runner is always in a molten state, eliminating the need to wait for runner cooling. - High - speed production, suitable for high - volume manufacturing. | - Moderate cycle time, longer than hot runners but shorter than cold runners in some cases. - Moderate production speed, with a balance between the simplicity of cold runners and the efficiency of hot runners. |

| Product Quality | - Prone to defects such as cold - slug marks and weld lines due to the non - uniform cooling of the runner. - Lower dimensional accuracy in some cases due to the stress caused by runner solidification. | - High - quality products with fewer defects, better surface finish, and high dimensional accuracy. - Consistent filling of cavities, reducing the risk of weld lines and air traps. | - Moderate product quality. Some heat loss can cause inconsistent flow, which may lead to minor defects if not well - controlled. |

| Applicable Materials | - Suitable for a wide range of plastics, including both common and some engineering plastics. However, the recycling process may affect the properties of some sensitive materials. | - Compatible with most thermoplastics, but special considerations are needed for heat - sensitive materials as long - term heating may cause degradation. | - Applicable to many common plastics, but may not be suitable for plastics with very high processing temperature requirements or those that are extremely sensitive to heat loss. |

| Product Types | - Large - scale products with relatively low - cost requirements, such as plastic pallets, large containers. - Products where the runner waste does not significantly impact the overall cost. | - High - precision components, high - value products, and products with strict surface quality requirements, like optical lenses, medical devices, and high - end automotive interior parts. | - Medium - volume production of products with moderate quality requirements, such as some plastic toys, small - scale industrial components, and certain consumer goods. |

This comparison table can help manufacturers quickly assess and choose the most suitable runner type for their specific injection molding projects, taking into account various factors such as cost - effectiveness, production speed, and product quality requirements.

Yigu Technology's Perspective

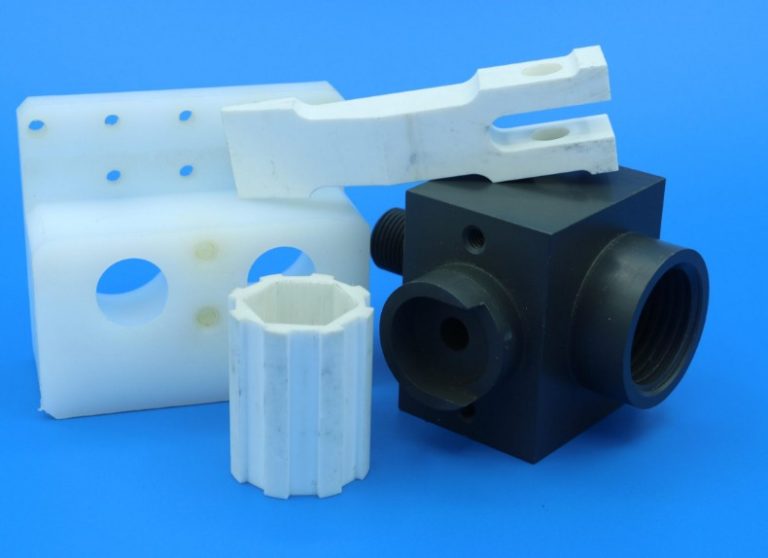

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in applying different runner types. In our production, we find that cold runners are suitable for some large - sized and cost - sensitive products. Their simplicity and low - cost mold structure are beneficial when the production volume is not extremely high, and the recycling of runner materials also helps to control costs to a certain extent.

For high - precision and high - value products, hot runner systems are our preferred choice. They enable us to achieve high - quality production with reduced defects and shorter cycle times. This not only improves product quality but also enhances our production efficiency, meeting the strict requirements of our customers in terms of product performance and delivery time.

Insulated runners are also utilized in specific scenarios where a balance between cost and production efficiency is needed. By carefully evaluating product requirements, production volume, and material characteristics, we can select the most appropriate runner type to ensure the best production results and customer satisfaction.

FAQ

What is the main difference between hot runner and cold runner?

The main differences lie in their structures, working methods, and material utilization. In a cold runner system, the runner channels are not heated. After injection, the molten plastic in the runner solidifies along with the parts and needs to be ejected and recycled, which leads to material waste. For example, in a large - scale plastic product production like plastic pallets, the runner waste can be significant. In contrast, a hot runner system uses heaters to keep the plastic in the runner in a molten state throughout the process. There is no need to eject the runner, eliminating runner waste. This not only simplifies the process but also reduces material costs, especially for high - value plastics. For high - precision components such as connectors in the electronics industry, hot runners are preferred for their waste - free and high - efficiency production.

When should I choose an insulated runner?

Insulated runners are a good choice in several scenarios. When the production volume is medium - sized, and you want to balance cost - effectiveness and production efficiency, insulated runners can be considered. They have a lower initial cost than hot runners and can reduce runner waste compared to cold runners. For products with moderate quality requirements, such as some plastic toys or small - scale industrial components, they are suitable. Also, when using plastics that are not extremely sensitive to heat loss and have relatively normal processing temperature requirements, insulated runners can work well. They are an option when you want to reduce the heat loss of the runner system without the high investment and complex maintenance of a hot runner system.

How does the runner type affect product quality?

The runner type has a significant impact on product quality. Cold runners are prone to issues such as non - uniform cooling, which can lead to cold - slug marks and weld lines. The non - uniform cooling also causes stress in the parts, potentially resulting in lower dimensional accuracy. For instance, in the production of plastic containers with cold runners, visible weld lines may appear on the surface. Hot runners, on the other hand, provide more consistent filling of the cavities. They can maintain a stable temperature of the molten plastic, reducing the occurrence of defects like weld lines and air traps. This results in products with better surface finish and higher dimensional accuracy, which is crucial for high - precision products such as medical devices. Insulated runners, due to some heat loss over time, may cause inconsistent flow. If not well - controlled, this can lead to minor defects in the molded parts, affecting the overall product quality to a certain extent.