The Significance of a Right Choice

Selecting the right plastic molding factory is pivotal for the success of your business. It's not merely a matter of finding a production partner; it's about forging a strategic alliance that impacts multiple aspects of your operations.

Product Quality

The quality of the plastic products directly influences your brand reputation. A proficient plastic molding factory, equipped with advanced technologies like high - precision injection molding machines and stringent quality control processes, can ensure that every product meets or exceeds industry standards. For instance, in the automotive industry, parts produced by a top - notch plastic molding factory have tight tolerances, which is crucial for the proper functioning and safety of vehicles. A study by the Plastic Industry Association showed that companies that switched to high - quality plastic molding suppliers saw a 30% reduction in product returns due to quality issues.

Cost Control

Cost - effective production is a cornerstone of business profitability. A well - managed plastic molding factory can help you optimize costs in several ways. They can source high - quality raw materials at competitive prices through long - term supplier relationships. Additionally, efficient production processes, such as reducing cycle times in injection molding, can lower labor and energy costs. According to research, companies that collaborate with plastic molding factories with lean manufacturing practices can save up to 20% on production costs.

Delivery Time

Timely delivery is essential in today's fast - paced market. A reliable plastic molding factory has a well - organized production schedule and effective supply chain management. They can handle unexpected production issues promptly without delaying the delivery of your products. In the consumer electronics industry, where new product launches are carefully timed, a delay in the delivery of plastic components can lead to missed market opportunities and significant financial losses.

Key Factors to Consider

When choosing a plastic molding factory, several key factors need to be carefully evaluated.

Production Capabilities

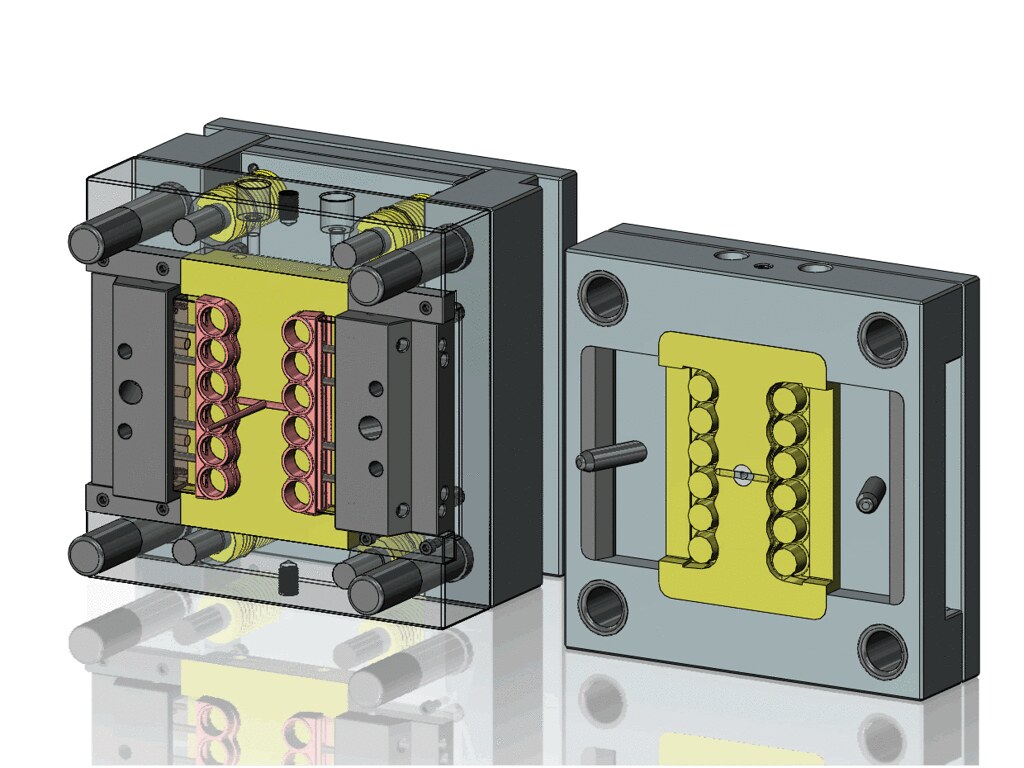

Molding Technologies

There are various plastic molding technologies, each with its own characteristics and applications. Injection molding is one of the most common methods. It involves melting plastic pellets and injecting the molten plastic into a mold cavity under high pressure. This technology is highly efficient and suitable for producing a wide range of products, from small precision parts like electronic components to large automotive interior parts. For Yigu Technology example, the housings of most consumer electronics, such as smartphones and tablets, are often made through injection molding.

Blow molding is mainly used for manufacturing hollow plastic products, such as plastic bottles, containers, and fuel tanks. The process starts with creating a plastic parison (a tube - like structure), which is then inflated with compressed air inside a mold to take the shape of the mold cavity. This method is cost - effective for high - volume production of hollow items.

Rotational molding, also known as rotomolding, is ideal for large, one - piece hollow products. In rotational molding, powdered or liquid plastic is placed inside a mold, which is then rotated on two axes while being heated. The plastic gradually coats the inner surface of the mold as it melts due to the combined effects of heat and rotation. Products like large storage tanks, playground equipment, and kayak hulls are typically made using rotational molding.

Capacity and Scale

The production capacity and scale of a plastic molding factory are crucial. A factory with a large number of advanced molding machines can handle larger orders. For instance, a factory equipped with 50 high - capacity injection molding machines can produce a significantly higher volume of products compared to a factory with only 10 machines. Additionally, the size of the production space matters. A spacious production area allows for better organization of the production process, storage of raw materials, and inventory management.

It's also important to consider the factory's ability to scale up production as your business grows. A reliable factory should be able to increase production output in a timely manner to meet the increasing demand for your plastic products without sacrificing quality.

Quality Assurance

Materials Sourcing

The quality of raw materials directly impacts the quality of the final plastic products. A good plastic molding factory sources materials from reliable suppliers. They should be able to provide documentation of the materials' origin, quality certificates, and test reports. For Yigu Technology example, if you need products made from high - grade polyethylene (PE), the factory should ensure that the PE pellets they use meet the required standards in terms of purity, molecular weight, and physical properties.

The factory should also have a strict raw material inspection process. This may include visual inspection for impurities, testing the material's physical properties like tensile strength and melting point, and checking for any chemical contaminants.

Quality Control Systems

A reliable plastic molding factory should have a comprehensive quality control system. ISO 9001 certification is a good indicator of a factory's commitment to quality management. Such a factory follows standardized procedures at every stage of production, from raw material inspection to the final product inspection.

The inspection process often involves the use of various testing equipment. For example, they may use coordinate measuring machines (CMMs) to accurately measure the dimensions of the plastic products to ensure they meet the design specifications. Quality control staff should be well - trained and have a clear understanding of quality standards and inspection procedures. Regular quality audits and continuous improvement initiatives are also essential parts of a robust quality control system.

Cost - Effectiveness

Pricing Structure

Plastic molding factories may have different pricing structures. Some charge by the piece, where the cost per unit is determined based on factors such as the complexity of the product, the amount of material used, and the production time. Others may charge based on the total order value, offering discounts for larger orders.

When comparing prices among different factories, it's important to consider the overall value rather than just the price. A factory that offers a lower price per piece may have lower - quality products or hidden costs. For Yigu Technology example, a factory with cheap production costs may use lower - grade raw materials, which could lead to product failures and higher costs in the long run due to returns and replacements.

Hidden Costs

There are several potential hidden costs that you need to be aware of. Mold design and modification costs can add up, especially if you require multiple design changes during the product development phase. Expedited order fees may be charged if you need your products to be produced and delivered in a shorter time frame than the normal production schedule. Shipping costs can also vary significantly depending on the distance, the volume of the products, and the shipping method. Some factories may quote a low production cost but have high shipping fees, so it's important to get a clear breakdown of all costs before making a decision.

Reputation and Experience

Industry Track Record

A factory's industry track record is a strong indicator of its reliability and expertise. You can review the factory's past projects to see the types of products they have produced, the industries they have served, and the quality of their work. For example, if a factory has a long - standing relationship with well - known automotive brands, it's likely that they have the technical capabilities and quality control measures in place to meet the high - standards of the automotive industry.

Customer reviews and testimonials can also provide valuable insights. Online platforms, industry forums, and business directories often contain feedback from previous clients. Positive reviews about a factory's product quality, delivery times, and customer service are signs of a reliable partner.

Customer Testimonials

Customer testimonials can give you a real - world perspective on a factory's performance. For example, a testimonial from a company that has been using a plastic molding factory for years and has consistently received high - quality products on time can be very reassuring. Testimonials may also highlight the factory's ability to handle complex projects, provide excellent customer support, and solve problems efficiently.

Customization and Design Support

Design Expertise

A good plastic molding factory should be able to offer design support. They can help optimize the product structure to improve its functionality and manufacturability. For example, they may suggest changes to the wall thickness, the placement of ribs, or the shape of the product to reduce material usage, improve strength, and simplify the molding process. In terms of appearance design, they can provide advice on color choices, surface finishes, and textures to enhance the product's aesthetic appeal.

Flexibility in Customization

The factory's ability to meet custom requirements is crucial. This includes producing products in special sizes, colors, and with unique functional features. For example, if you need plastic products with a specific color that matches your brand's color scheme, the factory should be able to source or mix the appropriate pigments. If your product requires a special functionality like built - in sensors or anti - microbial properties, the factory should have the technical know - how to incorporate these features during the molding process.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of choosing the right plastic molding factory. We prioritize seamless cooperation. A plastic molding factory that can communicate effectively and respond promptly to our needs is crucial. This includes clear communication channels during the design and production process, and quick resolution of any issues that may arise.

Moreover, we value technical complementarity. A factory with advanced molding technologies and innovative capabilities can bring added value to our projects. For example, their expertise in complex mold design can help us achieve unique product features. This collaborative approach, based on smooth cooperation and technical synergy, ensures high - quality product development and successful business outcomes.

FAQ

Q1: How can I tell if a plastic molding factory has good quality control?

You can start by checking if the factory has relevant certifications like ISO 9001. A certified factory adheres to international quality management standards. Examine their inspection process details. For example, ask about the frequency of in - process inspections during production. A good factory might conduct inspections every hour for high - precision products. Also, inquire about how they handle quality issues. Do they have a root - cause analysis system in place? A reliable factory will not only correct the problem but also take preventive measures to avoid its recurrence.

Q2: What if I have a small - volume order? Can I still find a suitable plastic molding factory?

Yes, you can. Some plastic molding factories have dedicated small - order production lines. They understand that small - volume orders are important for startups or for testing new product ideas. You can search for factories that explicitly state they welcome small - volume orders. However, be aware that the cost per unit for small - volume orders may be higher compared to large - volume orders. This is because the setup costs, such as mold preparation, are spread over a smaller number of products. But in some cases, factories might offer more flexible terms or even discounts for long - term small - volume orders.

Q3: Is it necessary to visit a plastic molding factory before placing an order?

Visiting a plastic molding factory before placing an order has many benefits. It allows you to see the production environment firsthand, ensuring it meets your cleanliness and safety standards. You can also inspect the equipment to assess its condition and modernity. Meeting the factory staff gives you an idea of their expertise and professionalism. However, if visiting is not feasible, you can arrange a video conference tour. This way, you can still get a good overview of the factory's operations, ask questions in real - time, and see the production processes in action, providing a preliminary understanding before making a decision.