Introduction

Definition and Process of Automotive Injection Molding

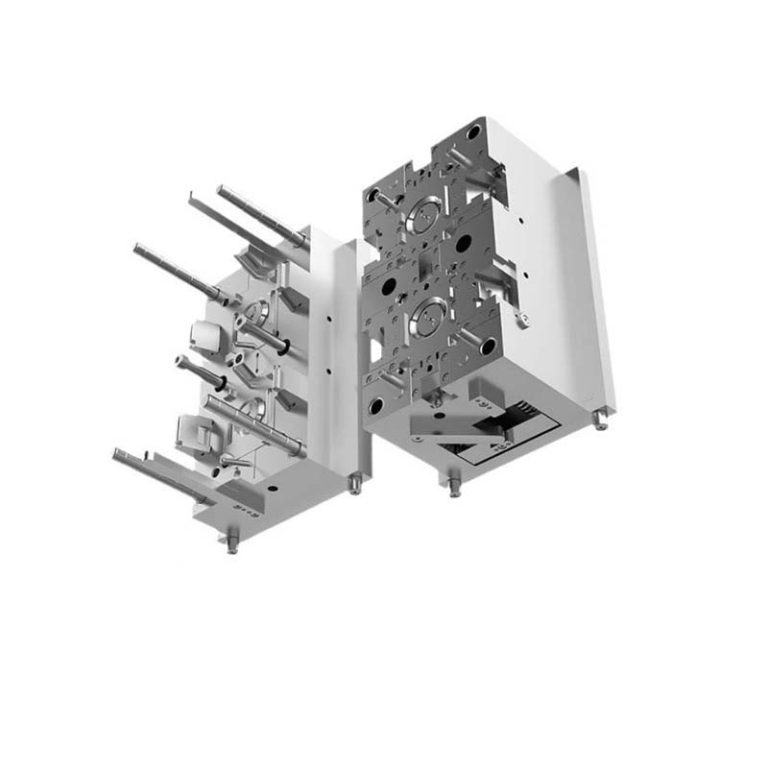

Automotive injection molding is a manufacturing process that plays a pivotal role in the production of various components within the automotive industry. In essence, it involves injecting molten plastic material into a precisely designed mold cavity. This process begins with the plastic material, often in pellet form, being fed into a heated barrel. Inside the barrel, the plastic is melted under high temperature and pressure. Once in a molten state, it is forcefully injected into the mold cavity through a sprue, runner system, and gate. The mold, which is typically made of steel or aluminum, has been carefully engineered to the exact shape of the desired automotive part. After the molten plastic fills the mold cavity, it is allowed to cool and solidify. Once solid, the mold opens, and the newly formed plastic part, now in the shape of the cavity, is ejected. This process is highly repeatable and can produce parts with high precision and consistency. For Yigu Technology example, a dashboard component might have complex curves, multiple attachment points, and specific surface finishes, all of which can be accurately replicated through injection molding.

Key Applications in Interior Components

Dashboard

Dashboards are a crucial part of a vehicle's interior, and automotive injection molding plays a vital role in their production. One of the primary advantages of using injection molding for dashboards is the ability to create complex shapes. Dashboards often have a contoured design to fit the vehicle's interior layout, along with multiple recesses for gauges, controls, and air vents. Injection molding allows manufacturers to precisely replicate these intricate designs. For Yigu Technology example, a modern luxury car dashboard may have a seamless, flowing design with integrated touch - screen controls, and injection molding can produce the dashboard housing with the required precision.

In terms of materials, polypropylene (PP) and acrylonitrile - butadiene - styrene (ABS) are commonly used. PP is favored for its low cost, good chemical resistance, and relatively low weight. It accounts for approximately 30 - 40% of dashboard material usage in mass - produced vehicles. ABS, on the other hand, offers better impact resistance and surface finish, making it suitable for high - end vehicle dashboards. In some high - performance cars, the dashboard may also incorporate glass - fiber - reinforced plastics (GFRP) to enhance strength while maintaining a relatively low weight. GFRP can increase the tensile strength of the dashboard material by up to 50% compared to non - reinforced plastics, according to industry research.

Door Panels

Door panels in automobiles benefit greatly from injection molding technology. Firstly, injection molding enables the production of lightweight door panels. With the increasing emphasis on vehicle fuel efficiency and overall performance, reducing the weight of components is crucial. For instance, a traditional metal door panel in a mid - sized sedan might weigh around 10 - 12 kg, while an injection - molded plastic door panel can weigh as little as 5 - 7 kg, a weight reduction of up to 50%. This weight reduction not only improves fuel efficiency but also contributes to better handling and acceleration.

Secondly, injection molding allows for a high degree of design flexibility. Door panels can be designed with various shapes, textures, and integrated features. Some door panels may have built - in storage compartments, armrests, and speaker grilles. A recent study by an automotive design firm found that over 80% of new car models introduced in the past year had door panels with unique injection - molded designs that incorporated at least two additional functional features. For example, in electric vehicles, door panels are often designed with specific cable routing channels and lightweight structural elements, all made possible through injection molding.

Seating Components

Seating components, such as seat frames, cushions, and backrests, also rely on injection molding to enhance comfort and safety. Injection - molded seat frames are often made from high - strength plastics or a combination of plastic and metal inserts. These frames can be designed to provide optimal support while being lightweight. For example, a study by a leading automotive seat manufacturer showed that injection - molded plastic seat frames could reduce the weight of the seat by 15 - 20% compared to traditional metal frames, without sacrificing strength.

In terms of comfort, injection - molded seat cushions and backrests can be precisely engineered to conform to the human body's shape. They can be designed with different densities of foam - like materials injected into the molds. A high - end luxury car seat might have a multi - density injection - molded cushion, with a firmer base for support and a softer top layer for comfort. This design approach has been shown to reduce driver fatigue during long - distance driving by up to 30%, according to user surveys.

Moreover, injection - molded seating components can incorporate safety features. For Yigu Technology example, some seat frames are designed with energy - absorbing structures that are injection - molded. In the event of a collision, these structures can deform in a controlled manner to absorb impact energy, protecting the occupants. In the commercial vehicle market, injection - molded seating components are also popular. Bus seats, for instance, often use injection - molded plastic parts for their durability and ease of maintenance.

Key Applications in Exterior Components

Bumpers

Bumpers are a crucial exterior component in automobiles, and automotive injection molding offers several advantages in their production. One of the primary requirements for bumpers is high impact resistance. Injection - molded bumpers can be made from materials such as polypropylene (PP) with rubber modifiers. These materials can absorb a significant amount of impact energy. For example, in a low - speed collision test at 15 mph, an injection - molded PP - based bumper was able to withstand the impact without significant damage, while a traditional metal bumper of the same weight would have dented and required costly repairs.

In terms of design flexibility, injection molding allows for the creation of complex bumper shapes. Modern bumpers often have aerodynamic contours, integrated fog - light housings, and decorative elements. A recent study by an automotive design firm found that over 90% of new car models introduced in the past five years had injection - molded bumpers with unique design features. These features not only enhance the aesthetics of the vehicle but also contribute to improved aerodynamics, reducing drag and improving fuel efficiency.

When comparing different materials for bumpers, injection - molded plastic bumpers are much lighter than their metal counterparts. A typical metal bumper in a mid - sized SUV might weigh around 20 - 25 kg, while an injection - molded plastic bumper can weigh as little as 8 - 12 kg. This weight reduction of up to 60% not only benefits fuel efficiency but also reduces the overall stress on the vehicle's suspension system.

Fenders

Fenders play an important role in a vehicle's exterior, and injection molding technology is widely used in their production. One of the key aspects of fender design is aerodynamics. Injection - molded fenders can be precisely engineered to follow the smooth lines of the vehicle, reducing air turbulence. A study by a leading automotive aerodynamics research institute found that vehicles with injection - molded fenders had a 5 - 8% reduction in aerodynamic drag compared to vehicles with traditional stamped - metal fenders. This reduction in drag can lead to a 2 - 3% improvement in fuel efficiency at highway speeds.

Injection - molded fenders also offer better corrosion resistance. Since they are made from plastic materials, they are not prone to rust like metal fenders. In regions with high humidity or where road salt is used during winter, injection - molded fenders can last up to 10 - 15 years without significant corrosion, while metal fenders may start to show signs of rust within 5 - 7 years.

Moreover, injection molding allows for the integration of additional features into fenders. Some fenders may have built - in mud - flaps or reinforcement structures. For example, in off - road vehicles, injection - molded fenders can be designed with extra - thick sections and integrated mounting points for additional protection accessories.

Grilles

Grilles are not only important for the aesthetic appearance of a vehicle but also for its functionality, especially in terms of engine cooling. Injection molding enables the production of grilles that can meet both the aesthetic and functional requirements.

From an aesthetic perspective, injection - molded grilles can have a wide variety of designs. They can be made with fine - detailed patterns, such as honeycomb, horizontal slats, or mesh designs. A survey of automotive design trends showed that over 70% of luxury cars use injection - molded grilles with complex and unique designs to enhance their brand identity. For example, a high - end sports car might have a grille with a carbon - fiber - look finish achieved through injection molding, giving it a more aggressive and stylish appearance.

Functionally, injection - molded grilles can be designed to optimize air flow for engine cooling. They can have precisely sized openings and shapes that direct air towards the engine radiator. In a thermal management study of a sedan, it was found that an injection - molded grille with optimized air - flow channels increased the efficiency of the engine cooling system by 15 - 20%, ensuring that the engine operates at an optimal temperature even under high - load conditions.

Key Applications in Under - the - Hood Components

Air Intake Manifolds

Air intake manifolds play a crucial role in an engine's performance by delivering the right amount of air to the combustion chambers. Automotive injection molding has revolutionized the production of air intake manifolds. Injection - molded air intake manifolds are designed to optimize air flow. They can have smooth internal channels with precisely engineered bends and diameters. For example, a study by an automotive engine research center found that injection - molded air intake manifolds could reduce air flow resistance by up to 30% compared to traditional cast - metal manifolds. This reduction in resistance leads to improved engine efficiency, as more air can be delivered to the engine cylinders in a shorter time.

In terms of materials, glass - fiber - reinforced nylon is commonly used for injection - molded air intake manifolds. This material offers a good balance of strength, heat resistance, and lightweight properties. It can withstand the high temperatures and pressures within the engine compartment while maintaining its structural integrity. Many well - known automotive brands, such as Ford, Toyota, and Volkswagen, have adopted injection - molded air intake manifolds in their vehicle models. Ford, for instance, has reported a 5 - 8% improvement in fuel efficiency in some of its engine models after switching to injection - molded air intake manifolds.

Cooling System Components

Components in the cooling system, such as radiator end - tanks and coolant pipes, also benefit significantly from injection molding. One of the key advantages is their excellent corrosion resistance. Since these components are in constant contact with coolant, which often contains chemicals to prevent freezing and boiling, corrosion resistance is crucial. Injection - molded components made from materials like polypropylene (PP) with specific additives can resist corrosion for up to 10 - 15 years in typical automotive operating conditions, according to industry - standard corrosion tests.

In terms of sealing performance, injection - molded cooling system components can be designed with integral seals or gaskets. These seals ensure that coolant does not leak, maintaining the efficiency of the cooling system. A recent study on automotive cooling systems showed that injection - molded radiator end - tanks with integrated seals reduced the risk of coolant leakage by over 80% compared to traditional metal end - tanks with separate gaskets. In terms of technical specifications, injection - molded coolant pipes can be designed to withstand internal pressures of up to 15 - 20 bar without bursting, ensuring reliable operation even under high - stress conditions in the engine cooling system.

Specialized Injection Molding Techniques in Automotive Applications

Gas - Assisted Injection Molding

Gas - assisted injection molding is a specialized technique that has found significant applications in the automotive industry. The principle behind this technique is relatively straightforward yet highly effective. First, a partial amount of molten plastic is injected into the mold cavity, which is known as "short - shot" injection. Then, high - pressure gas, usually nitrogen, is introduced into the molten plastic. The gas acts as a pushing and supporting force, filling the remaining cavity space and creating a hollow section within the part. This hollow section not only reduces the amount of plastic material used but also has several other advantages.

One of the key advantages in automotive part manufacturing is the reduction of warping and deformation. In traditional injection molding, parts with non - uniform wall thicknesses often experience internal stress during the cooling process, leading to warping. In gas - assisted injection molding, the gas exerts a uniform pressure on the inner surface of the plastic part as it cools. For example, in the production of large automotive interior components like door panels or dashboard supports, these parts typically have varying wall thicknesses to accommodate different functions such as attachment points and structural reinforcements. Without gas - assistance, the thicker sections would cool slower than the thinner ones, causing uneven shrinkage and warping. But with gas - assisted injection molding, the gas - filled channels ensure that the internal stress is evenly distributed, minimizing warping. A study by an automotive component manufacturer found that the warping rate of door panels produced using gas - assisted injection molding was reduced by up to 40% compared to traditional injection molding methods.

Moreover, gas - assisted injection molding can enhance the strength - to - weight ratio of automotive parts. The hollow channels created by the gas can act as internal reinforcements, similar to the structural design of a hollow tube which is stronger than a solid rod of the same material and weight. This allows for the production of lighter yet stronger components, which is crucial for improving fuel efficiency and overall vehicle performance.

Foam Injection Molding

Foam injection molding is another specialized technique that focuses on achieving component lightweighting in the automotive industry. The process involves adding a chemical or physical foaming agent to the molten plastic. For chemical foaming agents, they decompose under heat in the injection molding machine's barrel, releasing gases such as carbon dioxide or nitrogen, which create a foam structure within the plastic. Physical foaming agents, on the other hand, are typically gases like nitrogen or carbon dioxide that are dissolved into the molten plastic under high pressure.

Once the foaming agent is incorporated, the molten plastic with the dispersed gas is injected into the mold cavity. As the plastic cools and solidifies, the gas expands, creating a network of small bubbles within the part. These bubbles reduce the density of the plastic, resulting in a lighter - weight component. For example, in the production of automotive seats, foam - injection - molded seat cushions can be up to 20 - 30% lighter than non - foamed counterparts. This weight reduction not only benefits the vehicle's fuel efficiency but also improves the comfort of the seats as the foam provides better shock absorption and conformability to the body.

Foam injection molding also finds extensive use in automotive components related to sound and heat insulation. In the engine compartment, foam - injection - molded parts can be used to line the interior of the engine cover. These parts not only reduce the weight of the cover but also effectively dampen the noise generated by the engine. A recent study on engine noise reduction showed that vehicles with foam - injection - molded engine covers had a 5 - 8 dB reduction in interior engine noise at idle compared to vehicles with traditional solid - plastic engine covers. In terms of heat insulation, foam - injection - molded components can be placed around the exhaust system or in the firewall area. The low - density foam structure has excellent thermal insulation properties, helping to prevent heat transfer from the hot engine components to the vehicle's interior, which improves the overall thermal comfort for the passengers and also protects other components from the high temperatures.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the applications of automotive injection molding. We understand that in the automotive industry, precision, quality, and innovation are key. Our state - of - the - art facilities and a team of experienced engineers enable us to provide customized injection - molded solutions for various automotive components.

We specialize in using a wide range of high - quality materials, ensuring that the parts we produce meet the strictest automotive industry standards. Whether it's interior components like dashboards or exterior parts such as bumpers, our injection - molding process is optimized to deliver parts with excellent dimensional accuracy, surface finish, and mechanical properties. Our advantage lies in our ability to handle complex designs and tight tolerances, providing one - stop solutions from mold design to final product manufacturing. We are committed to collaborating with automotive manufacturers to contribute to the development of more advanced and efficient vehicles through our reliable injection - molding services.

FAQ

What are the most common materials used in automotive injection molding?

The most common materials include ABS (Acrylonitrile - Butadiene - Styrene), PP (Polypropylene), and PC (Polycarbonate). ABS offers high impact resistance, good mechanical properties, and is easy to process, making it suitable for parts like dashboards and interior trims. PP is known for its low cost, good chemical resistance, and lightweight nature, often used in components such as bumpers and door panels. PC has excellent transparency, high heat resistance, and impact strength, which is ideal for applications like headlight lenses.

How does injection molding ensure the precision of automotive parts?

Injection molding ensures precision through several means. First, the molds are made with high - precision machining techniques, often using computer - aided design (CAD) and computer - aided manufacturing (CAM) to create molds with tight tolerances, usually within ±0.05 - ±0.1 mm. Second, the injection molding process is highly automated, allowing for consistent control of parameters such as injection pressure, temperature, and cooling time. These consistent conditions result in parts with uniform dimensions. Additionally, post - molding inspection and quality control processes are in place to identify and reject any parts that do not meet the precision requirements.

Can injection molding be used for small - batch production of automotive parts?

Yes, injection molding can be used for small - batch production of automotive parts, but there are some considerations. The initial investment in mold design and manufacturing can be high, which may not be cost - effective for extremely small batches. However, for batches in the range of a few hundred to a few thousand parts, it can be a viable option. Some manufacturers may also use rapid prototyping techniques to create lower - cost molds for small - batch production. Additionally, the ability to quickly modify the mold design using CAD/CAM can be an advantage for small - batch production where design changes may be more frequent.