Introduction

Injection moulding machines play a pivotal role in modern industrial production. These versatile machines are used to create a vast array of plastic products that we encounter in our daily lives, from the smallest components in electronic devices to large automotive parts. Their importance lies in their ability to transform raw plastic materials into precisely shaped, high - quality products with high efficiency and repeatability.

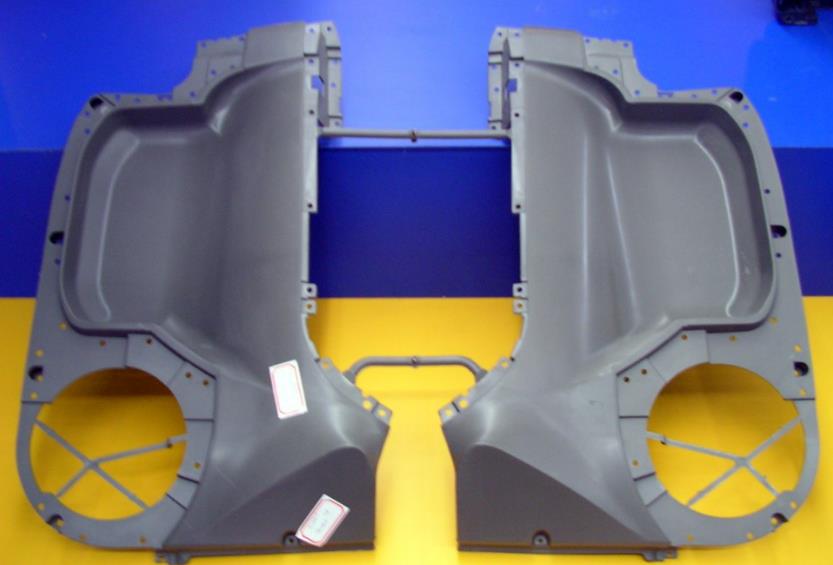

For instance, in the automotive industry, injection moulding machines are used to manufacture interior components such as dashboards, door panels, and seat trims. In the consumer electronics sector, they produce casings for smartphones, tablets, and laptops. Without injection moulding machines, the mass - production of these plastic products would be either extremely costly or simply unfeasible.

The key to the injection moulding machine's functionality lies in its components. Each part has a specific role, and understanding these components is crucial for anyone involved in plastic product manufacturing, whether it's an engineer, a technician, or a business owner looking to optimize production processes. In this article, we will explore the various components of an injection moulding machine in detail, shedding light on how they work together to create the plastic products we rely on.

The Heart of the Operation: Injection Unit

1. Screw

The screw is the central component of the injection unit in an injection moulding machine. Its primary functions include plasticizing the raw plastic pellets and transporting the plastic melt forward. As the screw rotates within the barrel, it traps the plastic pellets in its helical grooves. Through a combination of shear forces generated by the rotation and the heat from the barrel's heating elements, the plastic pellets are gradually melted and transformed into a homogeneous, viscous melt.

There are different types of screws designed for various applications. For example, general - purpose screws are suitable for a wide range of common plastics like polyethylene (PE) and polypropylene (PP). These screws have a relatively simple design with a constant pitch along their length. In contrast, barrier screws are specifically engineered for polymers that are difficult to plasticize uniformly, such as polyvinyl chloride (PVC). Barrier screws feature a special section that separates the solid and molten plastic, enhancing the plasticizing efficiency and ensuring better melt quality. Another type is the high - compression screw, which is ideal for materials that require a high degree of compaction during the plasticizing process, like glass - filled plastics. High - compression screws have a large difference in the depth of the screw grooves at the feed and metering sections, enabling efficient compression of the plastic material.

2. Barrel

The barrel works in tandem with the screw. It provides a confined space where the plasticizing process takes place. The barrel is typically made of high - strength alloy steel to withstand the high pressures and temperatures generated during the plastic processing. For instance, materials like 38CrMoALA are commonly used due to their excellent wear - resistance, high - temperature resistance, and good machinability.

The barrel is equipped with a heating system, usually consisting of electrical heating bands wrapped around its outer surface. These heating bands are controlled by a temperature controller to maintain precise temperature profiles along the length of the barrel. The heating zones are crucial as different plastics have different melting points and processing temperature requirements. For example, when processing polystyrene (PS), the temperature in the barrel may be set to around 180 - 260°C, while for engineering plastics like polycarbonate (PC), the temperature needs to be in the range of 250 - 320°C. The proper temperature control in the barrel ensures that the plastic is melted uniformly and has the right viscosity for injection. Additionally, some barrels also have a cooling system, often in the form of water - cooled channels near the feed section. This helps to prevent premature melting of the plastic pellets at the inlet, ensuring smooth feeding and efficient plasticizing.

3. Nozzle

The nozzle is the final component through which the plastic melt exits the injection unit and enters the mould. Its main function is to control the flow rate and flow pattern of the plastic melt. There are several types of nozzles, each with its own set of advantages and disadvantages.

The open - ended nozzle is the simplest type. It has a straightforward design where the plastic melt can flow freely out of the nozzle when pressure is applied. This type of nozzle is suitable for applications where a large volume of plastic needs to be injected quickly, such as in the production of large - scale plastic products like plastic buckets. However, an open - ended nozzle has the drawback of potential drooling, which means that plastic may leak out of the nozzle when the injection pressure is released, leading to waste and possible defects in the product.

The shut - off nozzle, on the other hand, addresses the drooling issue. It is equipped with a valve mechanism that can close the nozzle opening when the injection is complete, preventing any unwanted plastic leakage. This makes it ideal for applications where precision and clean injection are required, such as in the production of small, intricate plastic parts like electronic components. But shut - off nozzles are more complex in design and may require more maintenance to ensure the proper functioning of the valve mechanism.

Another type is the hot - runner nozzle, which is commonly used in hot - runner systems. In a hot - runner system, the plastic melt remains in a heated runner system and nozzle, eliminating the need for cold runners (the solidified plastic channels in traditional moulds). Hot - runner nozzles can improve material utilization and production efficiency as there is no waste of plastic in the form of cold runners. However, they require a more sophisticated heating and temperature control system, which increases the initial investment cost.

Power and Precision: Clamping Unit

The clamping unit is another crucial part of an injection moulding machine, and it consists of several components that work in harmony to ensure the efficient operation of the injection moulding process.

1. Toggles

Toggles, also known as toggle mechanisms, are a key component in many injection moulding machine clamping units, especially in hydraulic - mechanical clamping systems. The working principle of a toggle mechanism is based on the leverage and kinematic characteristics of a series of interconnected links.

When the hydraulic cylinder exerts a force on the toggle mechanism, the links in the mechanism translate this force into a much larger clamping force. The toggle mechanism consists of multiple articulated rods. As the hydraulic cylinder extends, the rods rotate and pivot around their joints. When the mechanism reaches its fully extended position, the rods align in a nearly straight - line configuration, creating a high - leverage situation. This alignment allows the relatively small force from the hydraulic cylinder to be amplified significantly, resulting in a large clamping force that can hold the mould firmly closed during the injection process.

One of the main advantages of toggle mechanisms is their compact structure. They can generate a large clamping force within a relatively small physical space, which is beneficial for manufacturers who need to optimize the footprint of their injection moulding machines. For example, in a small - to - medium - sized injection moulding machine used for producing plastic toys, a toggle - based clamping unit can provide the necessary clamping force while keeping the overall machine size manageable. Additionally, toggle mechanisms are known for their high - speed operation capabilities. They can quickly close and open the mould, reducing the cycle time of the injection moulding process. This is crucial for high - volume production scenarios where every second saved in the production cycle can lead to increased productivity.

2. Hydraulic Cylinders

Hydraulic cylinders are the power source behind the clamping action in most injection moulding machines. Their primary role is to provide the linear force required to move the moving parts of the clamping unit, such as the moving plate, and to generate the clamping force to hold the mould closed.

Hydraulic cylinders work based on Pascal's principle. Pressure is applied to a hydraulic fluid (usually oil) in a closed - system cylinder. The force exerted by the hydraulic fluid on the piston inside the cylinder is calculated by the formula \(F = P\times A\), where \(F\) is the force, \(P\) is the pressure of the hydraulic fluid, and \(A\) is the cross - sectional area of the piston. In injection moulding machines, the hydraulic pressure can range from 100 to 300 bar (10 - 30 MPa). For instance, a hydraulic cylinder with a piston diameter of 200 mm (radius \(r = 100\ mm=0.1\ m\)) and a hydraulic pressure of 150 bar (\(15\times10^{6}\ Pa\)) can generate a force \(F=\pi r^{2}P=\pi\times(0.1)^{2}\times15\times 10^{6}\approx471239\ N\).

Hydraulic cylinders also enable fast opening and closing of the mould. The speed of the cylinder's piston movement can be controlled by regulating the flow rate of the hydraulic fluid. During the opening phase, a high - flow rate of hydraulic fluid can be directed to the cylinder to quickly separate the mould halves, reducing the time required for part ejection and mould preparation for the next cycle. In the closing phase, the speed can be adjusted to ensure a smooth and gentle contact between the moulds, preventing damage to the moulds and the parts being produced.

3. Moving and Fixed Plates

The moving and fixed plates are essential components that support the mould during the injection moulding process. The fixed plate, as the name implies, is stationary and is typically bolted firmly to the frame of the injection moulding machine. It provides a stable base for one half of the mould. The moving plate, on the other hand, is connected to the clamping mechanism (such as the toggle or directly to the hydraulic cylinder) and can move back and forth. It holds the other half of the mould.

When the mould is installed, the fixed - plate - mounted mould half remains in a fixed position, while the moving - plate - mounted mould half can be moved towards the fixed plate to close the mould during the injection phase and away from it to open the mould for part ejection. The moving plate must be able to move smoothly and precisely along guides or rails to ensure proper alignment of the mould halves.

Both plates are designed to withstand the high clamping forces generated during the injection process. They are usually made of high - strength materials such as steel or cast iron. For example, in a large - scale injection moulding machine used for automotive part production, the plates may be made of high - grade alloy steel to handle the extremely high clamping forces required to keep the large and complex moulds closed during the injection of molten plastic. Precision is of utmost importance for these plates. The surfaces where the moulds are mounted need to be machined to a high level of flatness and parallelism. Any deviation in these parameters can lead to uneven clamping forces on the mould, which may result in defective parts, such as parts with inconsistent wall thicknesses or flash (excess plastic around the edges of the part).

Brain of the Machine: Control Unit

The control unit of an injection moulding machine is like the brain, responsible for coordinating and controlling all the operations of the machine. It ensures that each component works in harmony and that the injection moulding process is carried out accurately and efficiently.

1. Programmable Logic Controller (PLC)

A Programmable Logic Controller (PLC) is at the core of the control unit in most modern injection moulding machines. The PLC is a digital computer used for automation of industrial processes, such as controlling the injection moulding process.

It controls various actions of the injection moulding machine, including the movement of the screw, the opening and closing of the clamping unit, and the operation of the heating and cooling systems. For example, during the injection phase, the PLC precisely controls the speed and rotation of the screw to ensure that the right amount of plastic melt is injected into the mould at a consistent rate. It can also adjust the injection pressure based on pre - set parameters and real - time monitoring of the process.

In an automated production line with multiple injection moulding machines, the PLC can be networked together. For instance, in a large - scale plastic product manufacturing factory that produces thousands of plastic parts per day, the PLCs of different injection moulding machines can communicate with each other and with a central control system. This allows for centralized monitoring and control, where operators can adjust the production parameters of multiple machines from a single location. The PLC can also be programmed to perform complex sequences of operations, such as automatically changing the mould and adjusting the machine settings for different product batches, greatly enhancing the efficiency and flexibility of the production process.

2. Human - Machine Interface (HMI)

The Human - Machine Interface (HMI) is an essential component that enables communication between the operator and the injection moulding machine.

One of its primary functions is parameter setting. Operators can use the HMI to input various process parameters, such as injection pressure, injection speed, holding pressure, cooling time, and mould temperature. These parameters are crucial for the quality of the final plastic product. For example, if the injection pressure is set too low, the plastic may not fully fill the mould cavity, resulting in incomplete parts. On the other hand, if it is set too high, it can cause flash or damage to the mould. The HMI provides an intuitive way for operators to adjust these parameters according to the requirements of different plastic materials and product designs.

The HMI also plays a vital role in state monitoring. It displays real - time information about the machine's operation, such as the current position of the moving parts, the temperature of different zones in the barrel, and the pressure in the hydraulic system. This allows operators to quickly assess the status of the machine and identify any potential issues. For example, if the temperature of a particular heating zone in the barrel deviates from the set value, the operator can take immediate action to adjust it.

Another important function of the HMI is fault alarm. When a malfunction occurs in the injection moulding machine, such as a sensor failure, a motor overload, or a hydraulic leak, the HMI will display an alarm message and may also trigger an audible alarm. The alarm message usually provides detailed information about the nature of the fault, helping operators to quickly diagnose and troubleshoot the problem. This reduces downtime and maintenance costs, as operators can address the issues promptly, minimizing the impact on production. In summary, the HMI is an indispensable tool for operators, making the operation and monitoring of injection moulding machines more convenient, efficient, and reliable.

Auxiliary Components for Smooth Operation

1. Cooling System

The cooling system is of utmost importance in the injection moulding process. Its primary function is to cool the mould, which in turn controls the temperature of the plastic during the moulding process. When the molten plastic is injected into the mould, it needs to be cooled rapidly and evenly to solidify into the desired shape. A well - functioning cooling system can significantly reduce the cooling time, which is a major factor in determining the cycle time of the injection moulding process. For example, in the production of plastic bottle caps, a fast - cooling system can enable a high - speed production line, increasing the output of bottle caps per hour.

There are several common cooling methods. Water - cooling is the most widely used method. In a water - cooling system, water is circulated through channels in the mould. These channels are strategically designed to ensure that the water can absorb heat evenly from the mould. The water absorbs the heat from the mould and the plastic, and then the warm water is pumped out and cooled in a heat exchanger, such as a cooling tower or a water - chiller, before being circulated back into the mould. Another cooling method is oil - cooling. Oil has a higher boiling point and better heat - transfer stability in some cases compared to water. Oil - cooling systems are often used when the moulding process requires more precise temperature control, such as in the production of high - precision optical lenses. Air - cooling is also an option, although it is less efficient than water - or oil - cooling. Air - cooling is usually used for small - scale production or when the heat generated is relatively low, like in the production of some small, simple plastic toys.

2. Lubrication System

The lubrication system in an injection moulding machine is crucial for reducing the wear and tear of mechanical components, thereby extending the overall lifespan of the equipment. During the operation of the injection moulding machine, many components, such as the screws, toggle mechanisms, and moving parts of the clamping unit, are in constant motion and subject to friction. Without proper lubrication, these components would experience rapid wear, leading to increased maintenance costs and potential production disruptions.

Commonly used lubricants in injection moulding machines include various types of oils and greases. For example, hydraulic oils are used in hydraulic systems to lubricate the hydraulic cylinders and valves, while grease is often applied to bearings and some moving parts with relatively slow - moving speeds. There are different lubrication methods. Manual lubrication is a basic method, where operators apply lubricant to specific components at regular intervals. However, this method is time - consuming and may not ensure consistent lubrication. Automatic lubrication systems are more advanced. These systems use pumps to distribute lubricant to multiple lubrication points at a set frequency and volume. For example, a centralised automatic lubrication system can supply lubricant to all the critical moving parts of the injection moulding machine, ensuring that each component is properly lubricated without the need for constant manual intervention.

3. Safety Devices

Safety devices are an essential part of injection moulding machines. Their primary purpose is to protect the operators from potential hazards during the operation of the machine.

One of the most common safety devices is the safety door. The safety door is interlocked with the machine's control system. When the safety door is opened during the injection moulding process, the machine immediately stops all operations, such as injection and clamping. This prevents the operator from accidentally coming into contact with the moving parts or the hot plastic.

The emergency stop button, usually a large, brightly - coloured button, is another crucial safety device. In case of an emergency, such as a mechanical malfunction or a dangerous situation, the operator can press the emergency stop button, which will halt all the machine's operations instantly, cutting off the power to the motors and hydraulic systems.

sensors are also widely used. These sensors create an invisible light curtain in front of the machine's dangerous areas, such as the mould - closing area. If an object, such as a hand, enters the light curtain, the sensor detects the interruption of the light beam and sends a signal to the control system to stop the machine, thus preventing accidents.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of injection moulding machine components. The right combination of components can make a huge difference in the quality and efficiency of production. For custom products, the injection unit's components like the screw and nozzle need to be carefully selected based on the plastic materials used. For example, when dealing with high - performance plastics in custom parts, a specialized screw design is crucial for proper plasticizing.

In the clamping unit, the choice of toggles or hydraulic cylinders affects the stability of the mould during the injection process, especially for complex non - standard moulds. The control unit is also vital as it allows for precise adjustment of parameters according to the unique requirements of each custom order. Yigu Technology emphasizes that understanding and selecting the appropriate components of an injection moulding machine is the key to successful custom plastic product manufacturing.