Injection moulding is the cornerstone of modern mass manufacturing, responsible for producing everything from tiny medical components to large automotive parts. But not all injection moulding is the same. The core principle—injecting molten material into a mould—branches into several specialized processes, each designed to overcome specific design, material, or production challenges. Understanding the different types of injection moulding processes—from the standard method to advanced techniques like gas-assisted and insert moulding—is crucial for engineers, product designers, and procurement specialists. This guide will walk you through the core methodologies, explaining not just how they work, but more importantly, why and when you would choose one over another. We’ll delve into the advantages and limitations of each process, provide real-world application case studies, and equip you with the knowledge to make an informed decision for your next manufacturing project, ensuring optimal strength, aesthetics, cost, and production efficiency.

What Is the Basic Principle Behind Injection Moulding?

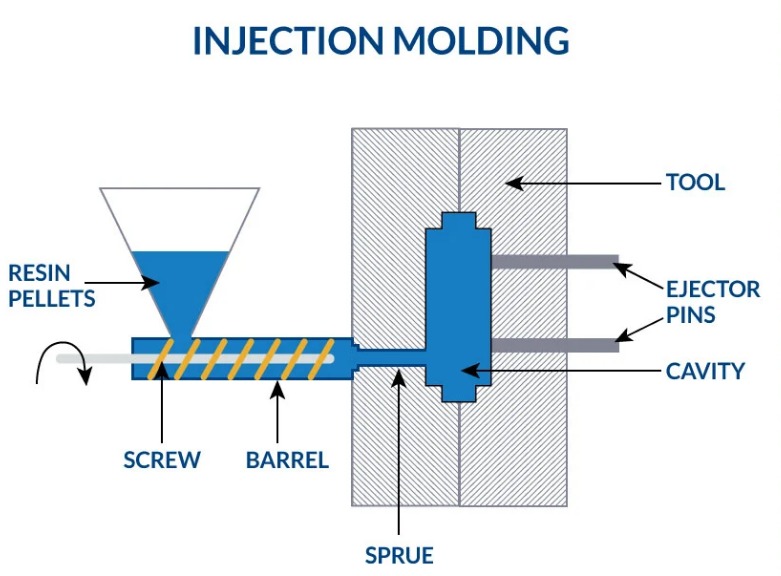

At its heart, injection moulding is a cyclical manufacturing process for producing parts by injecting molten material into a mould cavity. It's renowned for its high-volume production efficiency, excellent repeatability, and capacity for complex geometries. The fundamental steps are universal: material is fed into a heated barrel, mixed (plasticized), and forced into a mould cavity where it cools and hardens to the configuration of the cavity.

The machine itself consists of two main parts: the injection unit (which melts and injects the material) and the clamping unit (which holds the mould shut under pressure). The mould tool, often the most significant initial investment, is precision-machined from steel or aluminum and defines the part's shape, surface finish, and critical features. The choice of process variant becomes essential when the part design presents challenges that the conventional method can't solve cost-effectively, such as thick walls that sink, parts requiring metal inserts, or ultra-clear optical components.

What Are the Main Types of Injection Moulding Processes?

While the foundational machine is similar, process variations have been engineered to extend the capabilities of injection moulding. Selecting the right one hinges on your part's design specifications, material, and performance requirements.

How Does Conventional Injection Moulding Work?

Conventional, or standard, injection moulding is the most widely used process. It follows the basic steps: clamp close, inject, pack/hold, cool, plastify, clamp open, and eject. Its dominance is due to its unsurpassed speed for thin-walled parts and well-established, predictable processing parameters for a vast range of thermoplastics and some thermosets.

However, it has limitations. As wall thickness increases, so do problems like sink marks (indentations over ribs) and voids (internal air pockets) due to uneven cooling. Warpage can also occur. Therefore, it is ideal for parts with relatively uniform, thin walls. For example, the plastic housing of a computer keyboard is a classic application. The walls are thin and consistent, allowing for rapid cycle times and a flawless surface finish straight out of the mould. The tooling, while expensive, is designed for millions of cycles, making the per-part cost extremely low at high volumes.

Best for: High-volume consumer goods, containers, caps, and any part where design can be optimized for uniform, thin walls.

When Should You Consider Gas-Assisted Injection Moulding?

Gas-Assisted Injection Moulding (GAIM) is an innovative solution for manufacturing parts with thick sections without the defects. The process begins with a short shot—a partial injection of plastic into the cavity. Immediately after, an inert gas (usually nitrogen) is injected into the still-molten core of the thick section. The gas creates hollow channels, packing the plastic outwards against the mould walls with even pressure.

The benefits are substantial:

- Elimination of sink marks and voids in ribbed or thick areas.

- Significant material savings (up to 30-40%) due to the hollow cores.

- Reduced clamping force requirements, as less plastic is injected.

- Lower internal stresses and less warpage.

- The ability to produce large, structurally rigid parts in one piece.

A prime real-world case study is an office chair armrest. A conventional design would require thick plastic, leading to long cycle times, sink marks, and a heavy part. With GAIM, designers can create a part with thick, comfortable contours that are hollow inside. This results in a lighter, stiffer armrest with a perfect Class A surface finish, no sinks, and faster cooling due to the internal gas channels. The table below summarizes the key comparisons:

| Feature | Conventional Moulding | Gas-Assisted Moulding |

|---|---|---|

| Wall Thickness | Best for uniform, thin walls | Excellent for variable, thick walls |

| Surface Finish | Good, but sinks on thick ribs | Excellent, no sink marks |

| Part Weight | Higher (solid plastic) | Lower (hollow sections) |

| Material Use | Higher | Lower (10-40% savings) |

| Tooling Cost | Standard | Higher (requires gas pins/controls) |

| Ideal Application | Consumer electronics housings | Furniture, handles, automotive panels |

What Is Liquid Injection Moulding and Its Key Applications?

Liquid Injection Moulding (LIM) is fundamentally different as it processes liquid silicone rubber (LSR) and other thermoset materials. Instead of melting solid pellets, it uses a two-part liquid silicone system (base and catalyst) that is metered, mixed, and injected cold into a heated mould. The heat triggers a curing (cross-linking) reaction that solidifies the material into its final rubbery state.

This process is critical for products demanding high temperature stability, biocompatibility, and flexibility. The precision and cleanliness of LIM are unparalleled. For instance, in the production of medical-grade silicone seals for syringes, LIM is indispensable. The process is automated in a cleanroom environment. The liquid silicone is injected to form a perfect, flash-free seal. The material can withstand repeated sterilization (autoclaving), remains flexible, and is non-reactive with pharmaceuticals. Other key applications include infant care products (bottle nipples), automotive gaskets, and optical-grade keypads.

How Can Insert Moulding Enhance Part Functionality?

Insert Moulding is a versatile process where a pre-made component—often metal—is placed into the mould before injection. Plastic is then shot around it, creating a single, robust, integrated part. The inserts can be threads, electrical contacts, blades, or reinforcing members.

The primary advantage is the creation of strong, permanent bonds between dissimilar materials, eliminating the need for secondary assembly operations like press-fitting, adhesives, or ultrasonic welding. This enhances part reliability and reduces assembly costs. A classic example is a surgical scalpel handle. A metal blade (the insert) is robotically placed into the mould. A biocompatible plastic is then moulded around it, creating a handle that is ergonomically designed, provides a non-slip grip, and securely encapsulates the blade tang. This results in a single, sterile, ready-to-use device that is safer and more reliable than a two-piece assembled version.

FAQ

What is the most common type of injection moulding?

Conventional injection moulding is by far the most common process. It's the most cost-effective and efficient method for the vast majority of high-volume thermoplastic parts, especially those with consistent, thin walls like bottle caps, housings, and toys.

How do I choose between gas-assisted and conventional moulding for a thick part?

Choose Gas-Assisted Moulding if your thick-part design struggles with sink marks, warpage, or excessive weight/material use, and you need high surface quality. Choose Conventional Moulding if you can redesign the part to have more uniform, thinner walls (adding ribs for strength), as this will be more economical in tooling and processing.

Is liquid silicone moulding (LIM) more expensive than plastic moulding?

Yes, typically. The LSR material cost is higher than common thermoplastics. The processing equipment is specialized (metering/mixing units), and cycle times can be longer due to curing. However, for applications requiring its unique properties—extreme flexibility, heat resistance, biocompatibility—there is often no viable alternative.

What are the main benefits of using insert moulding?

The core benefits are part consolidation and enhanced reliability. By moulding plastic directly around inserts, you eliminate assembly steps, reduce labor costs, and create a mechanically superior bond that is often stronger and more consistent than posts-production assembly methods.

Contact Yigu technology for custom manufacturing.

Ready to bring your complex part design to life with the right injection moulding process? At Yigu Technology, our engineering team possesses deep expertise in all advanced moulding methodologies. We don't just supply parts; we become your manufacturing partner, analyzing your design to recommend the optimal process—whether it's gas-assisted for a flawless finish, insert moulding for integrated strength, or LSR for medical-grade flexibility. From design-for-manufacturability (DFM) feedback to precision tooling and high-volume production, we ensure your project achieves the perfect balance of performance, quality, and cost-efficiency. Contact us today for a confidential consultation and quote on your custom manufacturing project.