Understanding the Basics of Molding Factories

A molding factory, also known as a moulding factory, is a manufacturing facility that specializes in the production of molded products. The molding process involves shaping materials, such as plastic, metal, or rubber, into specific forms using molds. This technique is widely used across various industries due to its ability to produce complex and precise parts with high efficiency.

In the manufacturing world, molding factories play a pivotal role. They are the backbone of many industries, providing essential components that are used in a wide range of products. For example, in the automotive industry, molding factories produce interior components like dashboards, door panels, and seat parts. These parts not only need to fit perfectly within the vehicle but also meet strict safety and quality standards. In the electronics industry, they manufacture casings for smartphones, tablets, and other devices, which require high precision to protect the internal components and ensure a sleek design.

The importance of choosing the right molding factory for your project cannot be overstated. The quality of the products produced by the molding factory directly impacts the quality and functionality of the final product. A reliable molding factory can ensure that your components are produced with consistent quality, tight tolerances, and in a timely manner. On the other hand, a subpar factory may lead to issues such as defective parts, production delays, and increased costs. For instance, if a molding factory produces faulty plastic components for a medical device, it could potentially compromise the safety and effectiveness of the device, leading to serious consequences.

Key Factors to Consider

1. Experience and Expertise

Experience is a cornerstone when choosing a molding factory. An experienced factory has likely encountered a wide range of projects, from simple to complex. For example, a molding factory with over 10 years of experience in the automotive industry has probably dealt with the production of various car interior components, which often require high precision and strict quality control. They are more likely to have developed efficient production processes and problem - solving strategies over the years.

In contrast, a newly - established factory may struggle with complex geometries or tight tolerances. A study showed that factories with less than 3 years of experience had a 30% higher defect rate in complex molding projects compared to those with more than 5 years of experience. An experienced team can better anticipate potential issues during the molding process, such as material shrinkage or mold wear, and take proactive measures to address them. This not only ensures a higher quality product but also reduces production delays.

2. Equipment and Technology

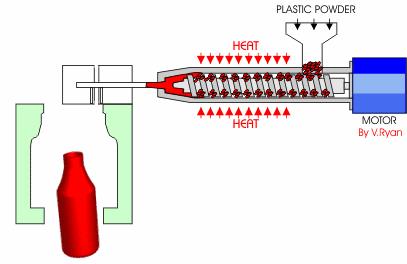

Advanced equipment and technology are essential for a high - quality molding process. High - precision injection molding machines can achieve tighter tolerances, which is crucial for products that require a perfect fit, such as components for medical devices or electronics. For instance, some state - of - the - art injection molding machines can maintain a tolerance of ±0.01mm, ensuring that the produced parts are consistent in size and shape.

3D printing technology is also becoming increasingly important in the molding industry. It allows for rapid prototyping, enabling factories to quickly produce samples for clients to review before mass production. This not only speeds up the product development cycle but also reduces costs associated with making changes to the design at a later stage. Additionally, the use of automation technology in the production line can increase production efficiency, reduce human error, and improve overall product quality.

3. Quality Control Measures

Strict quality control measures are non - negotiable in a reliable molding factory. The process typically starts with raw material inspection. For example, when using plastic pellets, the factory should test for properties such as melt flow index and moisture content to ensure they meet the required standards. During the production process, continuous monitoring is carried out. This may involve using sensors to monitor parameters like temperature, pressure, and injection speed in injection molding.

Finished product inspection is also crucial. Factories often use a combination of manual inspection and automated optical inspection (AOI) to check for defects such as surface flaws, dimensional inaccuracies, and functionality issues. Moreover, having international quality certifications, such as ISO 9001, indicates that the factory adheres to globally recognized quality management systems, giving clients added confidence in the quality of their products.

4. Production Capacity

The production capacity of a molding factory directly impacts its ability to meet your order requirements within the specified time frame. A large - scale factory with a high - volume production line can handle large - scale orders more efficiently. Consider the following table comparing the production capacities and average delivery times of different - sized molding factories for a specific plastic product:

| Factory Size | Monthly Production Capacity (Units) | Average Delivery Time for 10,000 Units |

| Small | 2,000 - 5,000 | 4 - 6 weeks |

| Medium | 5,000 - 10,000 | 2 - 4 weeks |

| Large | 10,000+ | 1 - 2 weeks |

If you have a large - scale project with tight deadlines, choosing a factory with sufficient production capacity can prevent delays and ensure that your products reach the market on time.

5. Cost - Effectiveness

While cost is an important factor, it should not be the sole determinant when choosing a molding factory. The cheapest option may not always be the best in the long run. A study found that products from factories with extremely low - cost production often had a 20% higher failure rate within the first year of use compared to products from moderately - priced factories. This can lead to increased costs due to product returns, replacements, and damage to your brand reputation.

Instead, look for a balance between cost and quality. A factory that offers a reasonable price while maintaining high - quality standards is the ideal choice. Some factories may offer cost - saving measures such as bulk order discounts or optimized production processes without sacrificing product quality. It's important to carefully evaluate the overall value each factory provides rather than simply focusing on the upfront cost.

Yigu Technology's Perspective

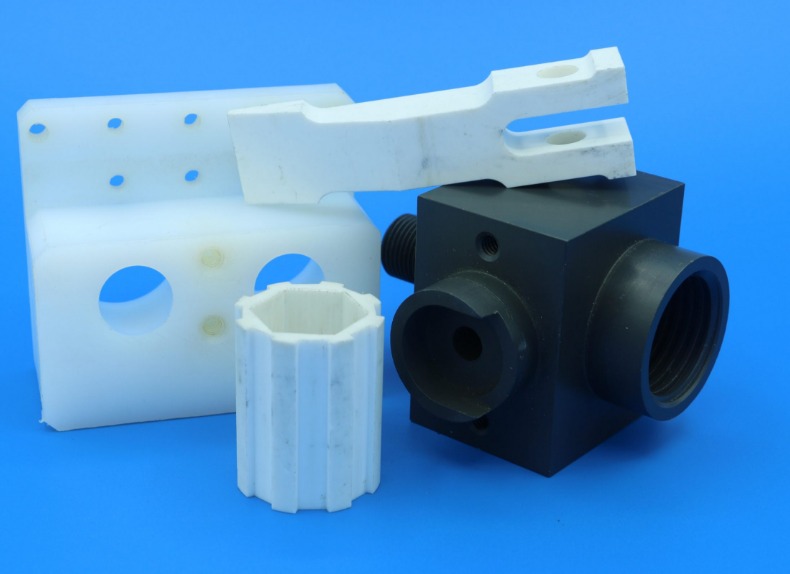

As a non - standard plastic and metal products custom supplier, Yigu Technology understands the significance of choosing the right molding factory. We believe that experience is the foundation. A molding factory with rich experience in non - standard production can better handle the unique requirements of each project. For example, they are more familiar with the processing of special materials and the manufacturing of complex - shaped molds.

Advanced technology and equipment are also crucial. Yigu Technology values molding factories that invest in high - end equipment, such as multi - axis machining centers for metal molding and high - precision injection molding machines for plastic products. This ensures that the products we receive meet our high - quality standards.

Moreover, we emphasize the importance of good communication and service. A molding factory that can communicate effectively, understand our needs promptly, and provide excellent after - sales service is an ideal partner. It helps to ensure the smooth progress of projects and the satisfaction of our customers.

FAQ

1. What questions should I ask a molding factory during the selection process?

You should ask about their production lead times for different order volumes. For example, how long it would take to produce 10,000 units of your product. Inquire about their quality control processes, such as what inspections are carried out during and after production. Ask about their after - sales service, like what they will do if there are defective products. Also, find out about their ability to handle design changes during the production process and any associated costs.