Understanding Rapid Prototyping

Rapid prototyping in product design is a revolutionary process that transforms a digital CAD (Computer-Aided Design) model into a tangible, physical model. This isn't just a simple translation from the virtual to the real; it's a cornerstone of modern product development.

The journey begins with a detailed CAD model, which serves as the digital blueprint of the product. Specialized software then slices this 3D model into thin, 2D cross - sections. These slices are like the pages of a book, each containing a specific layer of information about the product's shape. A rapid prototyping machine, such as a 3D printer, then reads these sliced files. It uses various materials, such as plastics, resins, or even metals depending on the technology and requirements, to build the model layer by layer. For example, in fused deposition modeling (FDM) 3D printing, a thermoplastic filament is melted and extruded through a nozzle, depositing the material precisely according to the sliced patterns to create each layer.

In the early stages of product development, rapid prototyping acts as a concept validator. Designers can quickly turn their abstract ideas into physical prototypes, allowing them to visualize and evaluate the form, fit, and function of their designs. For instance, a startup developing a new handheld fitness tracker can create a rapid prototype within days. This prototype enables them to check if the device feels comfortable in the hand, if the button layout is intuitive, and if the overall size is convenient for users to carry around.

During the mid - development phase, rapid prototyping is used for iterative design improvements. If user testing reveals that the fitness tracker's display is too small or difficult to read, the design can be modified in the CAD software, and a new prototype can be printed in a short time. This back - and - forth process of testing, modifying, and prototyping again significantly reduces the time and cost compared to traditional methods, where making design changes in later stages can be extremely expensive.

In the final stages, rapid prototypes can be used for pre - production validation, ensuring that the product meets all the necessary quality and performance standards before mass production begins.

The Advantages of Rapid Prototyping in Product Design

Time - Saving

In traditional product design, creating a prototype could take weeks or even months. For example, in the automotive industry, building a full - scale clay model for a new car design used to be a time - consuming process. However, with rapid prototyping, a basic prototype of a car interior component can be printed in a matter of days or even hours. A study by a leading design firm found that rapid prototyping reduces the prototyping time by an average of 70%. This time savings allows companies to bring products to market much faster. For a startup in the consumer electronics market, being able to quickly iterate on a new smartphone design prototype means they can enter the market ahead of competitors, capturing market share more rapidly.

Cost - Effective

Material Waste Reduction: Traditional manufacturing methods often involve subtractive processes, where material is removed from a larger block, resulting in significant waste. In contrast, rapid prototyping is an additive manufacturing process. For instance, in fused deposition modeling (FDM) 3D printing, only the necessary amount of plastic filament is used to build the prototype layer by layer. A research by a manufacturing institute shows that rapid prototyping can reduce material waste by up to 90% compared to traditional machining.

Avoiding Costly Design Errors: Making design changes in the later stages of traditional product development can be extremely expensive. With rapid prototyping, designers can quickly test and modify their designs. If a company is developing a new kitchen appliance and realizes through rapid prototyping that the handle design is uncomfortable, they can easily modify the CAD model and print a new prototype. This iterative process helps avoid costly errors in mass production. According to industry data, companies that use rapid prototyping can save up to 50% on development costs by detecting and fixing design flaws early.

Design Flexibility

Complex Geometries: Rapid prototyping allows for the creation of complex shapes that are nearly impossible to achieve with traditional manufacturing techniques. For example, in the aerospace industry, engine components with intricate internal cooling channels can be designed and prototyped using selective laser melting (SLM) technology. These complex geometries can improve the performance of the components, such as reducing weight while maintaining strength.

Customization: It enables easy customization of products. A jewelry designer can use rapid prototyping to create unique, customized pieces for clients. By inputting different design parameters into the CAD software, each piece can be tailored to the customer's preferences, whether it's a specific gemstone setting or a personalized engraving.

Different Rapid Prototyping Technologies and Their Features

1. Fused Deposition Modeling (FDM)

FDM works by melting a thermoplastic filament. A heated nozzle extrudes the melted material layer by layer onto a build platform. As the material cools, it solidifies, gradually forming the 3D object.

Advantages:

- Low Cost: FDM printers are relatively affordable, with some desktop models available for as low as a few hundred dollars. The cost of materials, such as PLA (Polylactic Acid) or ABS (Acrylonitrile Butadiene Styrene) filaments, is also relatively inexpensive, usually ranging from \(20 - \)50 per kilogram.

- Material Variety: It supports a wide range of materials, including PLA, ABS, PETG, and even some specialized filaments like conductive or flexible materials.

- Easy to Use: FDM printers are user - friendly, making them suitable for beginners in 3D printing and rapid prototyping.

Disadvantages:

- Lower Precision: The layer resolution is often limited, resulting in a relatively rough surface finish. The layer thickness typically ranges from 0.1 - 0.4mm, which may not be sufficient for high - precision applications.

- Slow Printing Speed: Printing speed can be slow, especially for complex models, as the nozzle needs to move precisely to deposit the material layer by layer.

In comparison with other technologies like SLA (Stereolithography), FDM is generally more cost - effective in terms of equipment and material costs. However, SLA offers much higher precision and a better surface finish. For example, SLA can achieve layer thicknesses as low as 0.025mm, while FDM struggles to go below 0.1mm in most cases. A comparison table is as follows:

| Technology | Cost (Equipment) | Cost (Materials per kg) | Precision (Layer Thickness) | Surface Finish |

| FDM | Low (\(100 - \)5000 for desktop models) | \(20 - \)50 | 0.1 - 0.4mm | Rough |

| SLA | High (\(5000 - \)50000+) | \(50 - \)200+ | 0.025 - 0.1mm | Smooth |

2. Stereolithography (SLA)

SLA uses a UV laser to cure a liquid photopolymer resin layer by layer. The laser traces the cross - section of each layer onto the surface of the resin, causing it to solidify. After each layer is cured, the build platform is lowered, and a new layer of resin is applied, repeating the process until the entire model is complete.

SLA is highly suitable for products that require high precision and a smooth surface finish, such as jewelry, dental models, and small - scale, intricate art pieces. For example, a jewelry designer can use SLA to create a detailed prototype of a ring with complex patterns and delicate filigree. The high precision of SLA ensures that every intricate detail of the design is accurately reproduced. A dental laboratory can also use SLA to create precise dental crown models for fitting and testing before production.

3. Selective Laser Sintering (SLS)

SLS works by using a high - power laser to sinter powdered materials, such as nylon, polyamide, or metal powders. The laser selectively fuses the powder particles together, layer by layer, according to the 3D model's cross - sections. After the printing process, the unsintered powder can be easily removed and reused.

In the manufacturing of functional parts, SLS has several advantages. It can produce parts with high strength and durability, suitable for applications in the automotive and aerospace industries. For example, SLS - printed nylon parts can be used as functional prototypes for automotive interior components. These parts can withstand the mechanical stresses and environmental conditions they will encounter in real - world use. Different materials perform differently in the SLS process. Nylon powders, for instance, are commonly used for their good mechanical properties, including high tensile strength and impact resistance. Metal powders in SLS can produce parts with excellent heat resistance and high - strength - to - weight ratios, making them ideal for aerospace applications. However, the cost of metal powders is significantly higher than that of polymer powders, and the processing of metal powders in SLS requires more specialized equipment and expertise.

Yigu Technology's Viewpoint

As a non - standard plastic and metal products custom supplier, Yigu Technology deeply understands the significance of rapid prototyping in product design. Our rich experience in this field allows us to effectively utilize rapid prototyping technology to meet diverse customer needs.

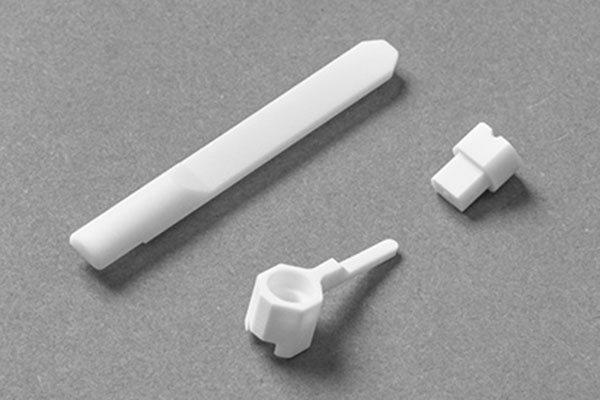

One of our key advantages lies in our unique process. We have optimized the rapid prototyping process to ensure high - quality results in a short time. For example, in handling complex plastic product designs, our advanced 3D printing equipment and precise process control enable us to accurately reproduce intricate details, which greatly helps in early design validation and improvement.

Material selection is another crucial aspect. We offer a wide range of high - quality materials, from engineering plastics with excellent mechanical properties to special - alloy metals for high - performance applications. This ensures that the prototypes we produce not only meet the design requirements but also have good physical and chemical properties, suitable for various functional tests. Whether it's a small - scale consumer product prototype or a large - scale industrial component prototype, Yigu Technology has the ability and experience to provide professional rapid prototyping services, helping customers accelerate their product development cycles and gain a competitive edge in the market.

FAQ

1. What are the most suitable materials for rapid prototyping?

Commonly used materials for rapid prototyping include ABS, PLA, and nylon. ABS (Acrylonitrile Butadiene Styrene) is a popular choice due to its high strength, good heat resistance, and excellent impact resistance. It is suitable for functional prototypes that need to withstand mechanical stress, such as automotive parts prototypes. PLA (Polylactic Acid) is a biodegradable material, which is environmentally friendly. It has a relatively low melting point, making it easy to process with FDM 3D printers. PLA is often used for creating prototypes with a focus on aesthetics and for applications where environmental friendliness is a concern, like in some consumer product prototypes. Nylon, especially in SLS rapid prototyping, offers high strength, good flexibility, and chemical resistance. It is ideal for making functional prototypes of parts that require durability, such as industrial tool prototypes.

2. How accurate is rapid prototyping compared to traditional manufacturing methods?

The accuracy of rapid prototyping varies depending on the technology used. In FDM, the layer thickness usually ranges from 0.1 - 0.4mm, which results in a relatively lower precision compared to some traditional methods. However, for many early - stage prototyping needs, this precision level is sufficient for form, fit, and function testing. SLA, on the other hand, can achieve much higher precision, with layer thicknesses as low as 0.025mm, providing a smooth surface finish and high - level detail reproduction, making it suitable for applications where high precision is crucial, like jewelry or dental model prototyping. Traditional manufacturing methods such as CNC machining can achieve extremely high precision, often in the micron range for metal parts. But rapid prototyping's advantage lies not in absolute precision in all cases but in its speed and cost - effectiveness for early - stage design iterations. Factors that can affect the accuracy of rapid prototyping include the quality of the 3D model, the calibration of the prototyping equipment, and the shrinkage or expansion properties of the materials during the cooling or curing process.

3. Can rapid prototyping be used for large - scale production?

Rapid prototyping has limitations when it comes to large - scale production. It is highly effective for small - batch production. For example, in the production of customized parts for a limited - edition product line, rapid prototyping can quickly produce the required components without the need for expensive tooling. The ability to quickly iterate and customize makes it a great choice for small - scale production runs. However, for large - scale production, several challenges arise. The production speed of most rapid prototyping technologies is much slower compared to traditional mass - production methods like injection molding. The cost per unit also remains relatively high in rapid prototyping due to the cost of materials and the time - consuming nature of the process. Additionally, the mechanical properties of some rapid - prototyped parts may not be consistent enough for high - volume, long - term use in large - scale production scenarios.