Understanding Prototyping

Definition and Significance

Prototyping is a fundamental and crucial step in the product development process. It refers to the creation of an early sample, model, or release of a product built to test a concept or process. This initial version is used to validate ideas, identify potential design flaws, and gather feedback before full - scale production.

In the automotive industry, for example, prototyping plays a pivotal role. Car manufacturers build multiple prototypes before finalizing the design of a new vehicle model. These prototypes are used to test various aspects such as aerodynamics, safety features, and engine performance. By doing so, they can make necessary adjustments and improvements, reducing the risk of costly mistakes during mass production. A study shows that about 70% of automotive companies believe that prototyping has significantly improved the overall quality of their final products.

Types of Prototypes

- Concept Prototypes: These are mainly used in the early stages of product development. Their primary purpose is to present the basic idea and design concept of the product. For instance, in the development of a new smartphone, a concept prototype might be a simple mock - up made of cardboard or 3D - printed plastic. It showcases the overall shape, size, and layout of the device, helping stakeholders visualize the product and provide initial feedback on the design concept. Concept prototypes are cost - effective and quick to produce, allowing for rapid iteration of ideas.

- Functional Prototypes: Once the concept is approved, functional prototypes come into play. These prototypes are designed to test the actual functionality of the product. In the case of the smartphone, a functional prototype would have a working display, basic operating system, and key functions like making calls and sending messages. It enables developers to identify any functional issues, such as software glitches or hardware - software compatibility problems. According to a survey, over 80% of software - related issues in new products can be detected during the functional prototyping stage.

- Appearance Prototypes: Focusing on the aesthetics of the product, appearance prototypes are made to show how the final product will look. They use high - quality materials and finishes to accurately represent the color, texture, and overall visual appeal of the product. For luxury watches, appearance prototypes are crucial as the brand's image is highly dependent on the visual allure of the product.

- Working Prototypes: These are fully - operational versions of the product that can be used for in - depth testing. A working prototype of a new medical device, for example, would be used by doctors and medical staff to test its effectiveness in real - life medical scenarios. It helps to ensure that the device meets all the necessary medical standards and requirements before mass production.

The Manufacturing Landscape

Traditional vs. Modern Manufacturing

The manufacturing landscape has evolved significantly over the years, with traditional manufacturing methods gradually being complemented and in some cases replaced by modern techniques. Here is a comparison between the two in terms of cost, efficiency, and precision:

| Aspect | Traditional Manufacturing | Modern Manufacturing |

| Cost | High initial setup cost for tooling and machinery. Labor - intensive, which can lead to high production costs, especially in regions with high labor wages. | Lower initial setup cost in some cases, especially for additive manufacturing (3D printing) which doesn't require extensive tooling. Can be more cost - effective in the long run due to reduced waste and automation. |

| Efficiency | Longer production lead times as processes may involve multiple steps and manual intervention. Limited flexibility in design changes during production. | Shorter lead times, especially with automated and digital manufacturing processes. High flexibility, allowing for quick design changes and customization. For example, in a modern automotive factory, robots can quickly adjust their movements based on digital instructions to produce different car models on the same production line. |

| Precision | Precision depends heavily on the skill of the workers. There can be variations in product quality from one unit to another. | High - precision manufacturing is achievable, with computer - controlled machines capable of producing parts with micron - level accuracy. In the aerospace industry, modern CNC (Computer Numerical Control) machines can manufacture engine components with extremely tight tolerances. |

Key Considerations in Manufacturing

- Material Selection: The choice of materials is crucial in manufacturing. Different materials have different properties such as strength, durability, weight, and cost. For example, in the construction of aircraft, lightweight yet strong materials like aluminum alloys and carbon - fiber composites are preferred. Aluminum alloys offer a good balance of strength and weight, while carbon - fiber composites are even lighter and stronger, but also more expensive. In contrast, for products where cost is a major factor, such as some consumer electronics housings, plastics are often used due to their low cost and ease of molding.

- Production Scale: The scale of production has a significant impact on both cost and quality. For small - scale production, methods like 3D printing or manual assembly may be more suitable. 3D printing allows for the creation of customized products without the need for expensive tooling, making it cost - effective for low - volume production. However, for large - scale production, mass - production techniques such as injection molding for plastics or stamping for metals are more efficient. These methods have high initial setup costs but lower per - unit production costs as the volume increases. In terms of quality, large - scale production often requires more rigorous quality control measures to ensure consistency across a large number of units.

Bridging Prototype and Manufacturing

From Prototype to Production - Transition Steps

The journey from prototype to production is a complex yet well - structured process. After creating a prototype, the first crucial step is prototype testing. This involves subjecting the prototype to a series of rigorous tests to evaluate its performance, durability, and functionality. For example, if it's a prototype of a new power tool, it will be tested for factors like how long the motor can run continuously without overheating, the strength of the housing under normal and extreme usage conditions, and the accuracy of the tool's operations.

Based on the test results, detailed feedback is collected. This feedback is then used to optimize the design. Designers may need to make changes to the shape, materials, or internal components. For instance, if the power tool prototype's housing shows signs of cracking during stress tests, the material might be changed to a more durable plastic or a metal alloy, and the design might be modified to distribute stress more evenly. This iterative process of testing and design optimization is repeated until the prototype meets all the required standards and specifications, making it ready for production.

Collaboration between Design and Manufacturing Teams

Collaboration between design and manufacturing teams is the cornerstone of a successful product development process. In a large - scale consumer electronics company, when developing a new tablet, the design team first creates the initial concept, focusing on aspects such as the overall look, user interface layout, and desired features. The manufacturing team then steps in, bringing their expertise in materials, production processes, and cost - effectiveness.

Together, they discuss how to make the design manufacturable. For example, the design team might have envisioned a very thin and sleek tablet body. The manufacturing team would then analyze whether the current manufacturing technology can produce such a thin structure without sacrificing strength and durability. They might suggest alternative materials or manufacturing techniques that can achieve the desired aesthetics while also meeting the production requirements. This kind of collaboration not only ensures that the final product can be produced efficiently but also helps in reducing costs. A study shows that companies with strong design - manufacturing collaboration can reduce production costs by up to 20% and shorten the time - to - market by about 30%. It also leads to higher - quality products as both the creative and practical aspects are considered from the early stages of development.

Yigu Technology's Perspective

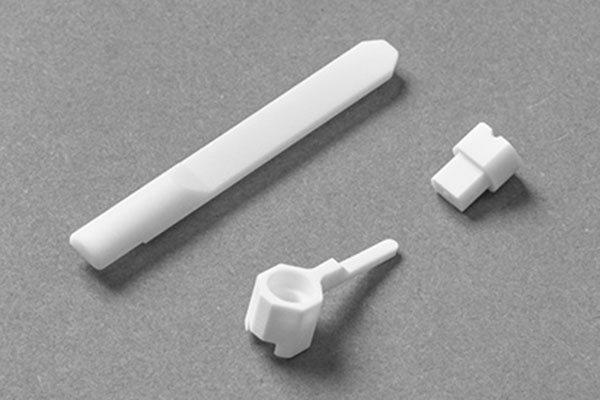

As a non - standard plastic and metal products custom supplier, Yigu Technology has rich experience in prototype and manufacturing. We understand that every client has unique requirements, and we are committed to providing customized solutions.

In the prototyping stage, we work closely with clients to transform their ideas into tangible prototypes. Our advanced design tools and skilled engineers enable us to create high - quality concept, functional, and working prototypes quickly. We conduct thorough tests on prototypes to ensure they meet all performance and quality standards.

When it comes to manufacturing, quality is our top priority. We source high - quality materials from reliable suppliers and use advanced manufacturing techniques. Our strict quality control system monitors every production step, from raw material inspection to the final product. This ensures that each product leaving our factory is of the highest quality. With Yigu Technology, clients can be confident in the entire prototype - to - production process.

FAQs

What are the common mistakes to avoid during prototyping?

- Neglecting User Needs: One of the biggest mistakes is not fully understanding and incorporating user requirements. For example, in the development of a mobile app, if the prototype doesn't consider the ease - of - use and functionality that users expect, such as a simple and intuitive navigation system, it may lead to a high rate of user abandonment. Research shows that about 60% of mobile apps with prototypes that ignore user needs fail to gain significant user adoption.

- Insufficient Testing: Failing to conduct comprehensive tests on prototypes can also be a major pitfall. This includes not only functional testing but also usability, stress, and compatibility testing. A software prototype that hasn't been properly stress - tested may crash when multiple users access it simultaneously, which could be disastrous for a product's reputation.

- Over - Design or Over - Engineering: Spending too much time and resources on making the prototype overly complex or perfect at an early stage is another common error. This can delay the development process and increase costs. Sometimes, a simple and basic prototype is sufficient to test the core concept, and unnecessary features can be added later based on user feedback.

How can I reduce manufacturing costs without sacrificing quality?

- Optimize Material Selection: As mentioned before, choosing the right materials is key. You can explore alternative materials that offer similar performance but at a lower cost. For instance, in some cases, high - strength plastics can be used instead of metals, reducing material costs without sacrificing too much on strength and durability. Additionally, by negotiating long - term contracts with reliable suppliers, you may be able to get better pricing for the materials you need.

- Improve Production Efficiency: Streamlining the production process can lead to significant cost savings. This can involve automating repetitive tasks, reducing production bottlenecks, and improving the layout of the production facility for better workflow. Implementing lean manufacturing principles can also help eliminate waste in the production process, such as overproduction, waiting times, and excess inventory. A company that successfully implemented lean manufacturing techniques reported a 15% reduction in production costs within a year.

- Enhance Quality Control: While it may seem counterintuitive, better quality control can actually reduce costs in the long run. By catching defects early in the production process, you can avoid the cost of rework or scrapping entire batches of products. Using advanced quality control tools like automated inspection systems can improve the accuracy and speed of quality checks.

What role does technology play in modern prototype and manufacturing?

- 3D Printing in Prototyping: 3D printing has revolutionized prototyping. It allows for the quick and cost - effective creation of prototypes with complex geometries. For example, in the design of a new prosthetic limb, 3D printing can rapidly produce a customized prototype based on a patient's unique body measurements. This not only speeds up the development process but also enables more design iterations. A study found that companies using 3D printing for prototyping reduced their product development time by an average of 30%.

- Artificial Intelligence in Manufacturing: AI plays a crucial role in modern manufacturing. It can be used for predictive maintenance, where AI algorithms analyze data from sensors on manufacturing equipment to predict when maintenance is needed, reducing unplanned downtime. AI - driven quality control systems can also quickly and accurately detect defects in products, improving overall product quality. In supply chain management, AI helps optimize inventory levels and logistics, reducing costs. The global market for AI in manufacturing is expected to grow significantly in the coming years, with a projected compound annual growth rate of over 30% from 2023 - 2032.