Introduction

In the landscape of global manufacturing, rapid prototyping services in China have emerged as a crucial element, playing a significant role in various industries. With the continuous advancement of technology and the transformation of the manufacturing industry, the demand for rapid prototyping services is on the rise. China, being a manufacturing powerhouse, has witnessed remarkable growth in this field.

The global market for rapid prototyping services has been expanding steadily, with a compound annual growth rate (CAGR) that reflects the increasing importance of this technology across industries such as automotive, aerospace, electronics, and medical. In this context, China's rapid prototyping services not only meet the domestic needs of a vast range of innovative companies but also serve the international market with high - quality and cost - effective solutions. This article aims to explore the various aspects of rapid prototyping services in China, from the available technologies and their advantages to the key players in the market and how they can assist you in bringing your product ideas to life quickly and efficiently.

Key Advantages of Rapid Prototyping Services in China

Cost - effectiveness

Cost is often a crucial factor for businesses when choosing rapid prototyping services. In China, the cost - effectiveness of these services is highly attractive. On average, rapid prototyping services in China can be 30% - 50% cheaper than in some Western countries. For example, a simple plastic prototype that might cost \(1000 in the United States could be produced for around \)500 - $700 in China. This cost advantage is mainly due to factors such as relatively lower labor costs, a well - developed supply chain that reduces material procurement costs, and government - supported policies that encourage the development of the manufacturing industry.

High - quality and Precision

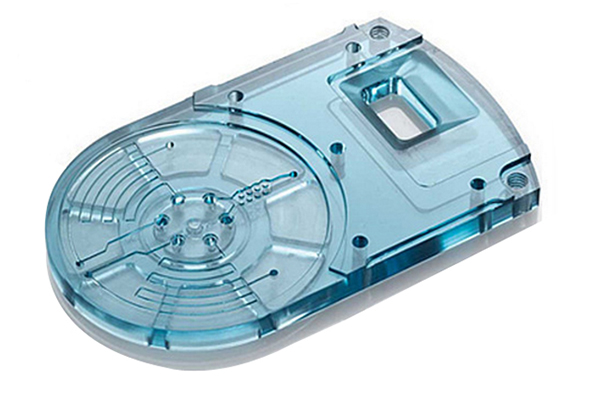

China's rapid prototyping services are not only cost - effective but also renowned for high - quality and precision. Advanced equipment like high - end 3D printers from leading global manufacturers, such as Stratasys and EOS, are widely used in Chinese rapid prototyping facilities. These printers can achieve layer thicknesses as low as 0.05mm, ensuring high - precision manufacturing. Moreover, a large number of highly skilled engineers and technicians with in - depth knowledge of CAD/CAM software work in this field. They can accurately translate complex design concepts into physical prototypes, meeting the strictest quality requirements of industries like medical device manufacturing, where precision is of utmost importance.

Diverse Material Options

China offers an extensive range of materials for rapid prototyping, providing customers with more choices to meet different application requirements. Here is a table showing some common materials and their characteristics:

| Material Type | Characteristics | Applications |

| PLA (Polylactic Acid) | Biodegradable, easy to print, relatively low cost, good for general - purpose prototyping | Consumer products, educational models |

| ABS (Acrylonitrile Butadiene Styrene) | High strength, heat - resistant, suitable for functional prototypes | Automotive parts prototypes, electronic enclosures |

| Nylon | Tough, wear - resistant, good chemical resistance | Mechanical parts, industrial components |

| Titanium Alloy | High strength - to - weight ratio, corrosion - resistant, suitable for aerospace and high - end applications | Aircraft components, medical implants |

Fast Turnaround Time

Time - to - market is a critical factor for product success. In China, rapid prototyping service providers are known for their fast turnaround times. On average, a simple prototype can be completed within 3 - 5 working days, while more complex ones may take 7 - 10 days. In contrast, in some European countries, the same prototypes might take 1 - 2 weeks. This efficiency is achieved through advanced production management systems, high - productivity equipment, and a large - scale workforce that can work in shifts to ensure continuous production. Reducing the product development cycle helps businesses gain a competitive edge in the market by quickly introducing new products or making design improvements.

Technological Expertise and Innovation

China has made remarkable progress in rapid prototyping technology. For instance, some Chinese research institutions and companies have developed innovative 3D printing technologies. One such innovation is a new type of multi - material 3D printing technology that can print different materials simultaneously, enabling the creation of more complex and functional prototypes. This technology has been applied in the development of customized medical devices, where different materials with specific properties are required to meet the unique needs of patients. Chinese experts in this field are also actively involved in international research projects and contribute to the global development of rapid prototyping technology.

Industry Experience and Track Record

China's rapid prototyping services have a rich industry experience and a solid track record. In the automotive industry, many Chinese rapid prototyping companies have successfully produced prototypes for new car models, helping automotive manufacturers to quickly test and optimize their designs. In the aerospace industry, they have provided high - precision prototypes for aircraft components, ensuring the safety and performance of the final products. For example, a leading Chinese rapid prototyping service provider has worked with a major domestic aerospace company to produce prototypes for a new unmanned aerial vehicle, which has been successfully tested and is now in production. These successful cases demonstrate the reliability and expertise of Chinese rapid prototyping services.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology plays a vital role in the rapid prototyping service chain. We firmly believe that understanding customer needs precisely is the foundation of providing excellent rapid prototyping services. Our team of experienced engineers engages in in - depth communication with customers from the very beginning. We take the time to understand not only the basic design requirements but also the end - use scenarios, performance expectations, and any specific challenges the customers anticipate. This meticulous approach allows us to translate the customers' abstract ideas into accurate design blueprints, ensuring that the final prototype meets and even exceeds their expectations.

In terms of product quality, Yigu Technology has a strict quality control system. We source high - quality raw materials from reliable suppliers, ensuring that the materials used in rapid prototyping have stable performance and excellent properties. During the production process, multiple quality inspection points are set up. Our advanced inspection equipment, such as high - precision 3D scanners and coordinate measuring machines, can accurately detect any potential dimensional or structural defects. We adhere to high - standard manufacturing processes, continuously optimize production parameters, and train our employees to improve their operational skills. All these efforts are aimed at delivering high - quality rapid prototypes to our customers, enabling them to have full confidence in our products and services.

FAQ

What is the typical turnaround time for rapid prototyping services in China?

In China, the typical turnaround time for rapid prototyping services varies depending on the complexity of the prototype and the technology used. For simple prototypes made by common 3D printing methods like FDM (Fused Deposition Modeling), it usually takes 3 - 5 working days. For more complex prototypes that require advanced technologies such as SLA (Stereolithography) or involve multiple post - processing steps, the time may be extended to 7 - 10 working days. Factors affecting the turnaround time include the complexity of the design, the availability of materials, and the workload of the service provider. For example, if a prototype has intricate internal structures or requires a special combination of materials, it will take longer to produce.

How can I ensure the quality of rapid - prototyped parts?

To ensure the quality of rapid - prototyped parts, first, choose a qualified and experienced rapid prototyping service provider. Check their track record, customer reviews, and certifications. For instance, a provider with ISO 9001 certification usually has a more reliable quality management system. Second, establish clear quality requirements and specifications before starting the project. Provide detailed 3D models and dimensional tolerances. Third, implement a strict quality inspection process. This can include in - process inspections during the prototyping process and final inspections using advanced measuring equipment like 3D scanners to check for dimensional accuracy.

What types of materials are commonly used in rapid prototyping services in China?

Commonly used materials in rapid prototyping services in China include plastics, metals, and composites. Among plastics, PLA (Polylactic Acid) is popular for its biodegradability and ease of printing, often used in consumer product prototypes and educational models. ABS (Acrylonitrile Butadiene Styrene) is favored for its high strength and heat - resistance, suitable for automotive parts prototypes and electronic enclosures. In terms of metals, aluminum alloys are widely used due to their low density and good mechanical properties, applied in aerospace and automotive component prototypes. Titanium alloys, with their high strength - to - weight ratio and corrosion - resistance, are used for high - end applications such as aircraft components and medical implants. Composites like carbon fiber - reinforced plastics are used when high strength and lightweight properties are required, for example, in the production of sports equipment prototypes.