Understanding the Importance of Medical Device Prototyping

Medical device prototyping is the cornerstone of innovation in the medical industry. It serves as the crucial link between a theoretical concept and a tangible, life - saving product.

Facilitating Innovation

In the constantly evolving medical field, new ideas for treating diseases, improving diagnosis, and enhancing patient care are constantly emerging. Medical device prototyping allows these concepts to be transformed into physical models. For example, in the development of minimally invasive surgical tools, prototyping enables engineers and medical professionals to experiment with different designs. They can test the functionality, ergonomics, and safety of the tools before mass production. This not only speeds up the innovation process but also ensures that the final product is of high quality. According to a report by Grand View Research, the global medical device market size was valued at USD 532.03 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. A significant part of this growth can be attributed to continuous innovation driven by prototyping.

Improving Treatment Outcomes

Well - designed medical device prototypes directly contribute to better treatment outcomes. Take the case of implantable medical devices like pacemakers. Through prototyping, manufacturers can optimize the size, power consumption, and functionality of the device. A more compact and efficient pacemaker prototype can lead to less invasive implantation procedures, reduced patient recovery times, and improved long - term cardiac function. In the area of diagnostic devices, prototyping helps in developing more accurate and sensitive tools. For instance, new prototypes of MRI machines are being developed to provide higher - resolution images, allowing doctors to detect diseases at earlier stages and formulate more effective treatment plans.

Reducing Risks and Costs in Production

Prototyping serves as a risk - mitigation strategy in medical device manufacturing. By creating prototypes early in the development cycle, companies can identify and address design flaws, material compatibility issues, and manufacturing challenges. This reduces the likelihood of costly recalls or product failures after mass production. For example, if a prototype of a new infusion pump shows problems with the accuracy of the dosage delivery, the design can be modified before investing in large - scale production. A study by the U.S. Food and Drug Administration (FDA) found that products with thorough prototyping and testing phases are less likely to face regulatory issues, saving companies both time and money in the long run.

Key Factors to Consider When Selecting a Company

Experience and Expertise

When evaluating medical device prototyping companies, experience is a key factor. A company with a long - standing presence in the industry is more likely to have encountered and overcome various challenges. For example, a company that has been in business for over 10 years has likely worked on a diverse range of projects. You should look into their past projects. Have they worked on prototyping for surgical instruments, diagnostic devices, or implantable devices? A company that has experience in multiple areas can bring a broader perspective to your project. According to a survey by the Medical Design & Outsourcing magazine, companies with more than 5 years of experience in medical device prototyping are 30% more likely to complete projects on time and within budget.

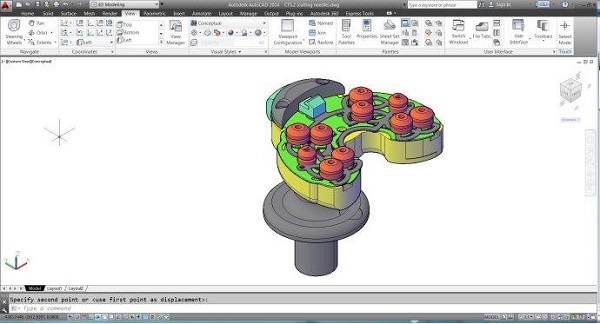

Technological Capabilities

Advanced technological capabilities are essential for high - quality medical device prototyping. Here are some key technologies and their advantages presented in a table:

| Technology | Advantage |

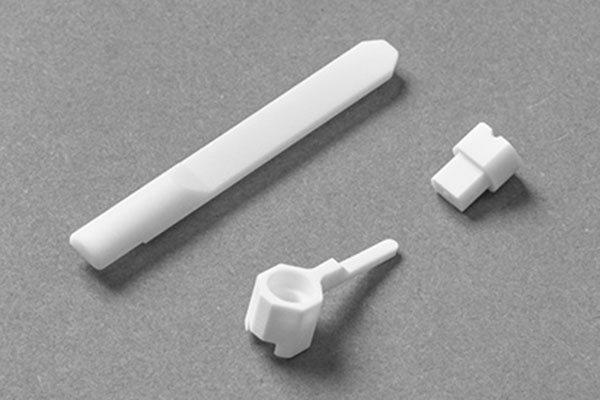

| 3D Printing | Allows for rapid creation of complex geometries. It can produce customized parts quickly, reducing the lead time for prototypes. For example, in dental implant prototyping, 3D printing can create a model that precisely fits the patient's jaw structure. |

| Simulation Software | Helps in predicting the performance of the device before physical production. This reduces the need for costly physical prototypes and allows for design optimization. For instance, fluid dynamics simulation can be used to analyze the flow of blood in a new cardiovascular device prototype. |

| CNC Machining | Offers high precision in manufacturing parts. It is suitable for creating components with tight tolerances, which is crucial for medical devices. In the production of surgical tools, CNC machining can ensure the exact shape and size requirements are met. |

Regulatory Compliance

Medical devices are strictly regulated to ensure patient safety. Compliance with relevant regulations and standards is non - negotiable. The US Food and Drug Administration (FDA) has a comprehensive set of regulations for medical devices. In the European Union, the CE marking indicates that a product complies with European health, safety, and environmental protection legislation. A company that is well - versed in these regulations can guide you through the complex process of getting your device approved. Failure to comply with regulations can result in costly delays or even product recalls. For example, in 2020, a medical device company faced a recall of its product because it did not meet the FDA's labeling requirements, causing significant financial losses.

Quality Assurance

Quality assurance is a fundamental aspect of medical device prototyping. A reliable company will have a robust testing process. This may include material testing to ensure that the chosen materials are biocompatible and suitable for the intended use. For example, if a prototype is for a contact - lens - related device, the material must be thoroughly tested for its impact on the eye. According to a study by the Journal of Medical Devices, products with comprehensive quality assurance measures have a 40% lower failure rate in the market. The company should also have a clear standard for material selection. High - quality materials not only contribute to the performance of the device but also enhance its durability.

Cost and Turnaround Time

While cost is an important consideration, it should not be the sole determining factor. A company that offers extremely low prices may cut corners on quality. On the other hand, a very high - priced option may not always guarantee better results. It's about finding the right balance. You can negotiate with the company to see if there are ways to reduce costs without sacrificing quality. For example, choosing standard materials when possible instead of exotic ones can lower costs. Regarding turnaround time, a delay in getting the prototype can slow down the entire product development cycle. A company that can provide a reasonable and reliable timeline is preferred. Some companies may offer expedited services for an additional fee, which can be a viable option if time is of the essence.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of medical device prototyping. In terms of material selection, we focus on biocompatible plastics and high - quality metals. Biocompatible plastics like polyethylene terephthalate glycol (PETG) are popular for their excellent chemical resistance and biocompatibility, which are crucial for devices in contact with the human body. For metal components, stainless steel grades such as 316L are often chosen for their corrosion resistance and strength.

Our manufacturing processes are carefully tailored to meet the high - precision requirements of medical device prototypes. Our CNC machining services can achieve tight tolerances, ensuring that every part fits perfectly. This precision is vital, especially for components in surgical instruments or implantable devices. We also work closely with medical device prototyping companies, providing them with customized solutions that combine material expertise and advanced manufacturing techniques.

FAQs

What are the common mistakes to avoid when choosing a medical device prototyping company?

One common mistake is overlooking regulatory compliance. Some companies might not be fully aware of the complex regulations set by the FDA or other regulatory bodies, which can lead to costly delays or product rejections. Another pitfall is choosing a company solely based on price. A significantly lower - priced option may use sub - standard materials or have less - experienced staff. To avoid these, thoroughly research the company's regulatory knowledge and don't base your decision solely on cost. Consider the overall value they can provide in terms of quality, expertise, and compliance.

How can I ensure the confidentiality of my medical device prototype idea?

Before starting any project, sign a non - disclosure agreement (NDA) with the prototyping company. This legally binds them to keep your idea and any related information confidential. During the communication process, limit the information shared initially to only what is necessary for the company to understand the basic requirements. Also, ensure that the company has proper internal security measures in place, such as restricted access to project - related files and data encryption.

What kind of after - sales support should I expect from a medical device prototyping company?

A reliable medical device prototyping company should offer post - project support. This includes providing maintenance and repair services for the prototype if it malfunctions. They should also be able to offer advice on improving the prototype based on their experience. For example, if there are issues with the durability of a component, they can suggest alternative materials or manufacturing techniques. Additionally, they may provide training on how to use the prototype effectively, especially if it involves complex functionality.