Introduction

What is Medical Device Rapid Prototyping?

Medical device rapid prototyping is a technology that enables the quick production of physical models of medical devices based on digital designs. It's a crucial step in the development of new medical devices, allowing manufacturers to test and refine their designs before full - scale production.

In the medical industry, where innovation is key to improving patient care, rapid prototyping plays a vital role. For example, before a new surgical instrument is launched on the market, a prototype can be created to test its functionality, ergonomics, and safety. This helps in reducing the time - to - market for new medical devices. According to a study by the Medical Design & Outsourcing magazine, companies that utilize rapid prototyping can cut their product development time by up to 50%.

The process of medical device rapid prototyping typically involves several steps. First, a 3D digital model of the device is created using computer - aided design (CAD) software. This model serves as the blueprint for the prototype. Then, various rapid prototyping technologies such as 3D printing, CNC machining, or stereolithography are used to build the physical prototype layer by layer or through subtractive manufacturing processes.

For instance, 3D printing, also known as additive manufacturing, has become increasingly popular in medical device rapid prototyping. It can create complex geometries with high precision, which is especially useful for devices like custom - fit orthopedic implants. In contrast, CNC machining is more suitable for creating prototypes with high - tolerance mechanical components, such as those found in surgical power tools.

The Process of Medical Device Rapid Prototyping

Step - by - Step Breakdown

- Design Phase:

- Concept Generation: The journey begins with brainstorming ideas for the new medical device. For example, if developing a new type of insulin pump, the design team will consider factors like ease of use for the patient, accuracy of insulin delivery, and size. They will research existing products in the market and identify areas for improvement.

- CAD Modeling: Once the concept is clear, designers use Computer - Aided Design (CAD) software to create a 3D digital model of the device. CAD allows for precise control over dimensions, shapes, and internal structures. A study by Design News found that 95% of product development teams use CAD software in the design phase of medical device development. This digital model serves as the foundation for all subsequent steps in the rapid prototyping process.

- Material Selection:

- Biocompatibility: Since medical devices come into contact with the human body, biocompatibility is a top - priority. Materials like medical - grade silicone, titanium, and certain types of plastics are commonly used. For instance, in the case of a prosthetic limb, titanium is often chosen for its high strength - to - weight ratio and excellent biocompatibility.

- Mechanical Properties: Depending on the function of the device, materials need to have appropriate mechanical properties. A surgical instrument, for example, requires materials with high strength and durability, such as stainless steel alloys.

- 3D Printing or Other Prototyping Methods:

- 3D Printing (Additive Manufacturing):

- Fused Deposition Modeling (FDM): One of the most common 3D - printing techniques in medical device prototyping. FDM works by heating a thermoplastic filament, such as ABS or PLA, and extruding it layer by layer to build the physical model. It is relatively cost - effective and suitable for creating prototypes with simple geometries.

- Stereolithography (SLA): SLA uses a laser to cure layers of liquid photopolymer resin. This results in high - precision prototypes with smooth surfaces, making it ideal for devices with complex shapes, like custom - designed dental implants.

- CNC Machining (Subtractive Manufacturing): In CNC machining, a block of raw material is gradually carved away using computer - controlled cutting tools. This method is suitable for creating prototypes with high - tolerance mechanical components, such as the internal mechanisms of a surgical drill.

Technologies Involved

- 3D Printing Technologies:

- Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered materials, such as nylon or metal powders, into a solid object. It is beneficial for creating functional prototypes with high strength and durability. For example, in the development of a new orthopedic implant, SLS - printed metal prototypes can be tested for their mechanical properties.

- Digital Light Processing (DLP): DLP is similar to SLA but uses a digital micromirror device to project light patterns onto a resin, curing it layer by layer. It offers high - resolution printing and is often used for creating detailed prototypes, such as anatomical models for surgical planning.

- Other Technologies:

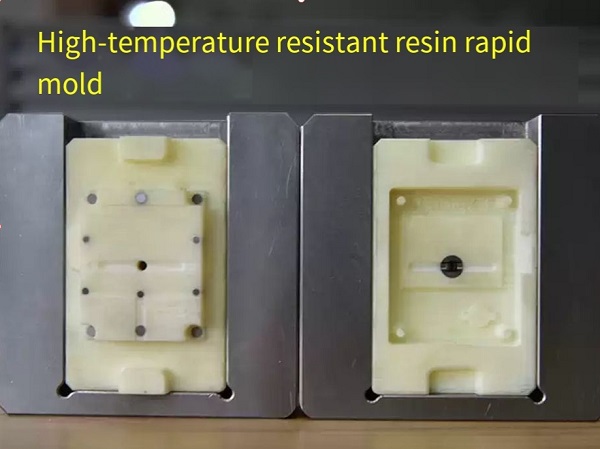

- Vacuum Casting: Vacuum casting is a technique used to create small - batch prototypes. A master pattern is created, and then a silicone mold is made around it. Liquid resin is poured into the mold under vacuum conditions to create the prototype. This method is useful for creating prototypes with smooth surfaces and accurate replication of the master pattern, like the outer casing of a medical monitoring device.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom supplier, Yigu Technology understands the critical importance of medical device rapid prototyping. We believe that high - quality material supply forms the basis of successful rapid prototyping in the medical device field. Our diverse range of biocompatible plastics and high - performance metals ensures that medical device prototypes can meet strict safety and functionality requirements.

Customization is at the core of our services. We work closely with medical device developers to understand their unique design needs. Whether it's a complex - shaped surgical instrument or a custom - fit implant, our precision manufacturing capabilities enable us to turn ideas into tangible prototypes. By leveraging advanced manufacturing techniques and a team of experienced engineers, we contribute to accelerating the development cycle of medical devices, helping our clients bring innovative products to the market faster.

FAQ

Q1: What are the most common materials used in medical device rapid prototyping?

Some of the most common materials include medical - grade silicone, which is highly biocompatible, flexible, and resistant to degradation. It's often used for devices like catheters. Titanium is another popular choice due to its excellent strength - to - weight ratio, biocompatibility, and corrosion resistance, making it suitable for orthopedic implants. Medical - grade plastics such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) are also frequently used. PC offers high impact resistance and transparency, while ABS is known for its good mechanical properties and ease of processing, and they are suitable for various parts of medical devices like housings and some internal components.

Q2: How long does the medical device rapid prototyping process usually take?

The time can vary depending on several factors. The design phase, including concept generation and CAD modeling, might take 1 - 2 weeks for a relatively simple device, but it could be 4 - 6 weeks or more for a complex one. Material selection usually doesn't add a significant amount of time, perhaps a few days. The actual prototyping process, if using 3D printing, can take anywhere from a few hours for a small, simple prototype to 2 - 3 days for a larger, more intricate one. CNC machining might take 3 - 5 days depending on the complexity of the part. So in total, the medical device rapid prototyping process can range from about 2 weeks for a very simple device to 8 weeks or more for a complex and high - precision one.

Q3: How do regulatory requirements affect medical device rapid prototyping?

Regulatory requirements have a significant impact. First, they influence material selection. Only biocompatible materials that meet strict standards, such as those set by ISO 10993 for biocompatibility, can be used. This limits the pool of available materials. The prototyping process also needs to be well - documented. Every step, from design changes to material testing, must be recorded for regulatory review. For example, in the EU, medical devices need to comply with the Medical Device Regulation (MDR), which requires comprehensive documentation of the development process. This documentation is crucial for getting regulatory approval in the later stages of product development, adding time and effort to the rapid prototyping process.