Introduction

In the fast - paced and highly competitive automotive industry, automotive rapid prototyping has emerged as a game - changing technology. It serves as a crucial bridge between the initial concept and the final production - ready vehicle.

The automotive market is evolving at an astonishing speed. Consumers are constantly demanding more advanced features, better fuel efficiency, and enhanced safety in their vehicles. At the same time, automakers face intense competition to bring new models to market faster than their rivals. This is where automotive rapid prototyping comes into play.

For example, in the past, developing a new car model could take years. Engineers had to rely on traditional manufacturing methods that were time - consuming and costly for creating prototypes. However, with the advent of rapid prototyping, the situation has changed dramatically. Now, a concept can be transformed into a physical prototype in a much shorter time frame, allowing for quicker design iterations and more efficient problem - solving. This not only accelerates the overall development process but also significantly reduces costs associated with trial - and - error during the design phase. As we move forward, we will explore the various aspects of automotive rapid prototyping, including its methods, materials, applications, and the advantages it offers over traditional manufacturing techniques.

The Basics of Automotive Rapid Prototyping

What is Automotive Rapid Prototyping?

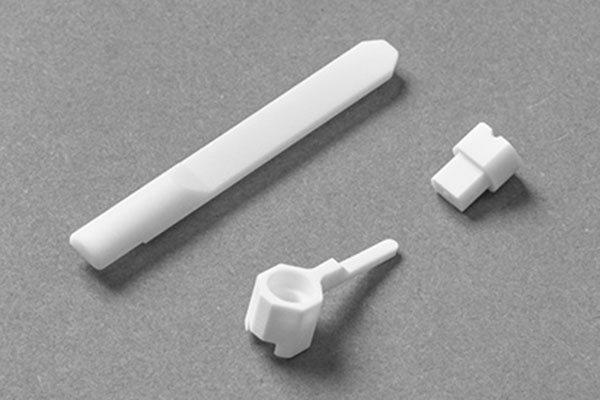

Automotive rapid prototyping is a revolutionary manufacturing process that enables the creation of three - dimensional physical models of automotive components or entire vehicle designs directly from digital designs. It serves as a crucial step in the automotive product development cycle, allowing automotive engineers and designers to quickly transform their ideas into tangible prototypes for testing, evaluation, and refinement.

The process begins with a digital 3D model created using computer - aided design (CAD) software. This model contains all the detailed specifications of the automotive part or vehicle, including its shape, size, and internal structure. Then, through the use of specialized rapid prototyping technologies, materials are added layer by layer to build the physical prototype based on the digital model. This approach is in sharp contrast to traditional manufacturing methods, which often involve time - consuming and complex processes such as machining, casting, or forging.

Key Technologies Involved

- Stereolithography (SLA): SLA is one of the earliest and most widely used 3D printing technologies in automotive rapid prototyping. It works by using an ultraviolet (UV) laser to cure layers of liquid photopolymer resin. As the laser traces the cross - sectional shape of the part on the surface of the resin, the exposed resin solidifies, layer by layer, to form the 3D object. SLA offers high precision and smooth surface finishes, making it ideal for creating detailed automotive prototypes, such as interior components with complex geometries or small, intricate parts. For example, it can be used to produce a highly detailed prototype of a car's dashboard control panel.

- Selective Laser Sintering (SLS): SLS uses a high - power laser to sinter powdered materials, such as plastics, metals, or ceramics, into a solid structure. The laser selectively fuses the powder particles together according to the cross - sectional pattern of the part, and the un - sintered powder acts as a natural support during the printing process. This technology is well - suited for creating functional prototypes in the automotive industry, as the sintered parts often have good mechanical properties. For instance, SLS can be used to manufacture strong and durable prototypes of automotive brackets or engine components that need to withstand certain mechanical stresses during testing.

- Fused Deposition Modeling (FDM): FDM is a popular and relatively affordable 3D printing technology. It extrudes a thin filament of melted thermoplastic material, such as ABS or PLA, through a heated nozzle. The nozzle moves in a precise pattern, depositing the material layer by layer to build the 3D object. FDM is often used for creating larger automotive prototypes or for rapid prototyping of parts where high precision is not the primary concern but cost - effectiveness and quick turnaround are important. An example would be the production of large, non - critical exterior body panels for initial design concept evaluation.

Applications in the Automotive Industry

Concept Validation

Automotive rapid prototyping plays a pivotal role in concept validation. In the early stages of vehicle design, creating a full - scale physical model is essential for evaluating the overall design concept. With rapid prototyping, car manufacturers can quickly produce concept car models. For example, Tesla often uses rapid prototyping to transform their innovative electric vehicle concepts into tangible prototypes. These prototypes allow designers and engineers to assess aspects such as the vehicle's aerodynamics, ergonomics, and overall aesthetic appeal. By having a physical model in hand early on, they can identify design flaws and make necessary adjustments more efficiently. In the past, without rapid prototyping, concept validation was a much more time - consuming process. It could take months or even years to build a concept model using traditional manufacturing methods, delaying the development cycle significantly.

Component Testing

It is also invaluable for component testing. Automotive components need to meet strict performance standards in terms of strength, durability, heat resistance, and more. Rapid prototyping enables the production of prototype components for comprehensive testing. For instance, when testing the strength of a new automotive suspension component, a prototype can be 3D - printed using materials with properties similar to the final production material. According to a study by an automotive research institute, prototypes made through rapid prototyping can accurately simulate the performance of production - level components in over 80% of cases during initial testing. These prototypes are then subjected to various stress tests, such as cyclic loading to measure fatigue life. In a durability test of a 3D - printed engine bracket prototype, it was found that it could withstand up to 100,000 cycles of simulated engine vibrations before showing signs of failure, which was a crucial data point for engineers to determine if the design was viable for production.

Customization

In today's market, consumers are increasingly demanding personalized vehicles. Automotive rapid prototyping provides an excellent solution for customization. Car enthusiasts can have their vehicle interiors customized according to their preferences. For example, a customer might want a unique - shaped center console or a custom - designed dashboard. A company that specializes in automotive customization used rapid prototyping to create a one - of - a - kind carbon - fiber dashboard insert for a luxury car owner. The insert was designed with intricate patterns and ergonomic adjustments to fit the owner's specific needs. This not only enhanced the aesthetic appeal of the vehicle but also improved the user experience. Another case is a car modification shop that used 3D - printed parts to create a custom - fit air intake system for a high - performance vehicle, optimizing its engine performance while adding a unique touch to the vehicle.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values automotive rapid prototyping. With years of experience in the field, we understand the significance of precise material selection and optimized manufacturing processes.

In material selection, we offer a wide range of options, from high - strength plastics to heat - resistant metals, ensuring that the prototypes can meet different performance requirements in the automotive industry. For example, when creating prototypes for engine components, we recommend and supply materials with excellent heat - resistance and mechanical strength.

Our team is also dedicated to process optimization. We have continuously improved our manufacturing processes to reduce production time and cost while maintaining high - quality standards. By leveraging advanced technologies and our in - depth knowledge of the industry, we can provide customized solutions for automotive rapid prototyping. Whether it's a small - scale concept model or large - scale component testing prototypes, Yigu Technology is committed to providing our clients with top - notch services and reliable solutions to support their automotive development projects.

FAQ

What are the common materials used in automotive rapid prototyping?

Common materials include:

- Photopolymer Resin: Used in SLA. It offers high precision and smooth surface finishes, ideal for detailed parts like interior components. For example, it can accurately replicate the fine details of a car's dashboard buttons.

- Plastic Powders (e.g., Nylon in SLS): Provide good mechanical properties. Nylon parts can withstand mechanical stresses, making them suitable for brackets or components that need to endure vibrations.

- Metal Powders (such as Aluminum, Titanium): These are used for high - strength and heat - resistant applications. Titanium powder can be sintered to create engine components that can operate in high - temperature environments.

How accurate is automotive rapid prototyping?

The accuracy of automotive rapid prototyping typically ranges from ±0.1mm to ±0.5mm, depending on the technology used. For instance, SLA can achieve high precision, often with an accuracy of around ±0.1mm. However, factors such as the complexity of the design, material shrinkage during the curing or cooling process, and the quality of the 3D printer itself can affect the accuracy. Larger parts may also experience more significant dimensional variations.

Can automotive rapid prototyping be used for mass production?

Currently, automotive rapid prototyping is not typically used for mass production. The main reasons are the relatively high cost per unit, slower production speed compared to traditional mass - production methods like injection molding or stamping, and limitations in material options for large - scale production. However, with the continuous development of 3D printing and related rapid prototyping technologies, in the future, it may become more viable for small - batch or customized mass production, especially for high - value or complex components where the flexibility of rapid prototyping can offer unique advantages.