Introduction

In the fast - paced world of product development, time is of the essence. Rapid prototyping parts have emerged as a game - changer, playing a crucial role in every stage of bringing an idea to a market - ready product.

Think about the initial concept stage. You have a brilliant idea for a new product, but how do you transform that abstract thought into something tangible? This is where rapid prototyping parts come in. They allow you to quickly create a physical model of your design, giving you and your team the ability to visualize and evaluate the concept in 3D. It's like having a crystal ball that can show you the potential flaws and strengths of your idea early on.

When it comes to design validation, rapid prototyping parts are invaluable. Instead of spending months on a full - scale production only to find out that the design has fundamental issues, you can use these parts to test the form, fit, and function of your product. For example, in the automotive industry, before investing millions in new car models, engineers create rapid prototyping parts of engine components, dashboards, and body panels. This way, they can identify problems such as poor ergonomics or inefficient air flow in the engine, and make necessary adjustments before mass production.

Moreover, rapid prototyping parts enable cost - effective experimentation. In traditional manufacturing, making changes during the production process can be extremely costly. However, with rapid prototyping, you can make multiple iterations of your design at a relatively low cost. You can try out different materials, shapes, and sizes to find the optimal combination that meets your product requirements while keeping costs in check. This not only saves you money but also shortens the overall product development cycle, allowing you to bring your product to market faster and gain a competitive edge. As we move forward, let's explore the different methods of creating rapid prototyping parts and how they can further benefit your product development journey.

What are Rapid Prototyping Parts?

Definition

Rapid prototyping parts are three - dimensional physical entities directly fabricated based on digital designs. In the past, turning a design idea into a physical model was a complex and time - consuming process. However, with the advent of rapid prototyping technology, this has become much more straightforward. These parts are created layer by layer, allowing for the production of highly complex geometries that were once extremely difficult or even impossible to achieve using traditional manufacturing methods. For example, in the aerospace industry, parts with intricate internal channels for fluid flow can be quickly prototyped, which helps in optimizing the performance of engines and other components.

Principle

The principle of rapid prototyping parts is based on the concept of discrete and accumulation forming. It combines multiple advanced technologies, including CAD (Computer - Aided Design), numerical control, laser technology, and new material technology. First, a 3D model is created using CAD software. This digital model serves as the blueprint for the physical part. Then, the model is sliced into thin layers in the computer. In the manufacturing process, the corresponding technology (such as laser sintering of powder materials or extrusion of molten plastics) is used according to the type of rapid prototyping technology. These technologies deposit materials layer by layer, precisely following the shape information of each layer of the sliced model, gradually building up the three - dimensional part. For instance, in Selective Laser Sintering (SLS), a high - power laser is used to sinter powdered materials, such as plastics or metals, layer by layer to form the final part.

Types of Rapid Prototyping Technologies

Stereolithography (SLA)

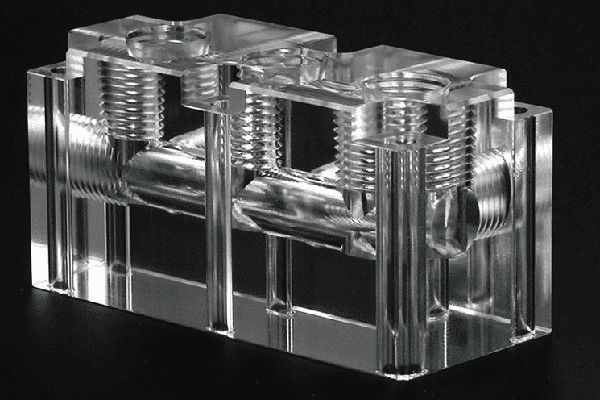

SLA is one of the earliest rapid prototyping technologies. It works by using a laser to cure a photosensitive resin layer by layer. In an SLA machine, a vat is filled with liquid photosensitive resin. A high - precision laser beam is directed by a computer - controlled system to trace the cross - sectional shape of the part on the surface of the resin. As the laser hits the resin, it cures, solidifying the resin into the desired shape for that layer. After one layer is completed, the build platform is lowered slightly, and a new layer of resin is spread over the previously cured layer. This process is repeated until the entire part is formed.

SLA is well - suited for applications that require high precision and smooth surface finishes. For example, in the jewelry industry, SLA can be used to create intricate and detailed wax - like prototypes of jewelry pieces. These prototypes can then be used for investment casting to produce the final jewelry items. In terms of precision, SLA can achieve layer thicknesses as low as 0.05 - 0.1 mm, which is much finer than some other rapid prototyping methods. The surface finish of SLA - printed parts is also relatively smooth, often requiring minimal post - processing, which is a significant advantage compared to technologies like Fused Deposition Modeling (FDM).

Fused Deposition Modeling (FDM)

FDM is another widely used rapid prototyping technology. In an FDM printer, a spool of thermoplastic filament, such as PLA (Polylactic Acid) or ABS (Acrylonitrile Butadiene Styrene), is fed into a heated extruder. The extruder melts the filament and then deposits it layer by layer onto a build platform. The extruder moves in the X and Y directions, following the path defined by the 3D model, while the build platform moves in the Z - direction to create the successive layers. As the melted plastic is extruded, it cools and solidifies quickly, bonding to the previous layer.

One of the main advantages of FDM is its cost - effectiveness. The equipment and materials used in FDM are generally more affordable compared to other rapid prototyping technologies. This makes it a popular choice for hobbyists, small businesses, and educational institutions. For example, a desktop FDM 3D printer can be purchased for as low as a few hundred dollars, and the cost of PLA filament is relatively inexpensive. FDM is commonly used for creating functional prototypes, such as mechanical parts for small - scale product testing. It can also be used for creating simple consumer products like custom - designed phone cases or small household items.

Selective Laser Sintering (SLS)

SLS is a powder - based rapid prototyping technology. In an SLS system, a bed of powdered material, such as nylon, metal powder, or ceramic powder, is pre - heated to a temperature just below the melting point of the powder. A high - power laser is then used to selectively sinter (fuse) the powder particles together, layer by layer, according to the cross - sectional shape of the 3D model. After one layer is sintered, a new layer of powder is spread over the previous layer, and the process repeats until the entire part is completed.

SLS is ideal for creating complex and high - performance parts. Since the powder supports the part during the building process, there is no need for additional support structures as in some other technologies like FDM. This allows for the creation of parts with intricate internal geometries and overhangs. For example, in the aerospace industry, SLS can be used to produce lightweight yet strong components with complex internal cooling channels. These channels are crucial for maintaining the temperature of engine parts during operation. SLS - printed parts also tend to have good mechanical properties, making them suitable for applications where strength and durability are important.

Applications of Rapid Prototyping Parts

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology has in - depth insights into rapid prototyping parts. With years of experience and advanced technical capabilities, we understand the unique needs of different industries for rapid prototyping.

Our technical team is proficient in multiple rapid prototyping technologies, such as SLA, FDM, and SLS. We can accurately select the most suitable technology according to the specific requirements of customers, whether it is high - precision jewelry prototypes or high - performance aerospace components. We also focus on material research and development, providing a wide range of material options to ensure that the rapid prototyping parts we produce not only meet the design requirements but also have excellent mechanical properties and durability. In addition, Yigu Technology adheres to a customer - centered service concept, providing one - stop solutions from design consultation to prototype production and after - sales service, aiming to help customers accelerate the product development process and achieve business success.

FAQs

What materials can be used for rapid prototyping parts?

Common materials for rapid prototyping parts include:

- Photocurable Resin: It is mainly used in Stereolithography (SLA) technology. It has high precision and smooth surface finish. The cured resin parts have good mechanical properties in some aspects, suitable for making detailed and high - precision prototypes, such as jewelry prototypes. However, it is usually sensitive to light and may change properties over time.

- Thermoplastic Plastics: For example, PLA and ABS are widely used in Fused Deposition Modeling (FDM). PLA is an environmentally friendly material, easy to use, and suitable for desktop 3D printers. ABS has better strength and heat resistance, often used for making functional prototypes that need certain strength. They are cost - effective and have a wide range of colors available.

- Metal Powders: Applied in Selective Laser Sintering (SLS) and some metal 3D printing technologies. Metals like stainless steel, aluminum alloy powder can be used to create high - strength and durable parts. Metal - based rapid prototyping parts are suitable for aerospace, automotive, and other industries where high - performance parts are required, such as engine components in the aerospace industry.

How accurate are rapid prototyping parts?

The accuracy of rapid prototyping parts is affected by various factors, especially the technology and equipment used. Different rapid prototyping technologies have different accuracy ranges. For instance, SLA technology generally has a relatively high accuracy, with layer thicknesses as low as 0.05 - 0.1 mm, which means the dimensional accuracy can reach a relatively high level, usually within ±0.1mm - ±0.01mm in ideal conditions. FDM technology, on the other hand, has a relatively lower accuracy compared to SLA. The layer thickness is usually around 0.1 - 0.4 mm, and the dimensional accuracy is generally within ±0.2mm - ±0.1mm. SLS - printed parts also have good accuracy, which can meet the requirements of many high - precision applications, with an accuracy range similar to SLA in some cases.

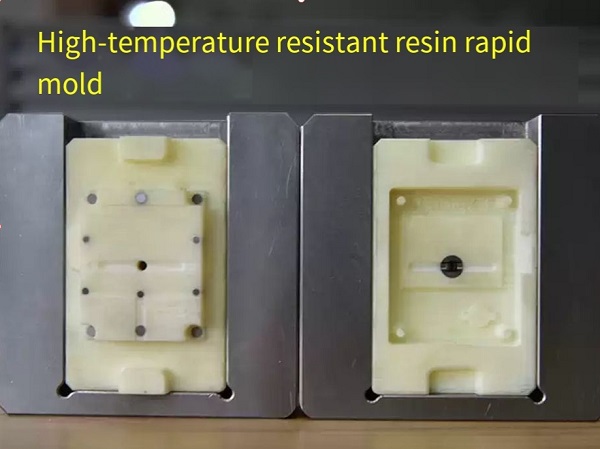

Can rapid prototyping parts be used for mass production?

Rapid prototyping parts are not typically ideal for large - scale mass production. The production speed of most rapid prototyping technologies is relatively slow compared to traditional mass - production methods like injection molding or stamping. For example, a single part may take hours or even days to print using 3D printing (a common rapid prototyping method). However, in small - batch trial production, rapid prototyping parts have significant cost and time advantages. They allow manufacturers to quickly produce a small number of parts for product testing, market validation, or customization, which can help reduce development costs and time - to - market. So, while not suitable for full - scale mass production, they play an important role in the early stages of product development and small - scale production needs.