Introduction to Short Run Plastic Parts

Definition and Applications

Short run plastic parts refer to the production of a limited quantity of plastic components, typically ranging from a few dozen to a few hundred units. This approach is commonly used in industries where high-volume production is not cost-effective or necessary. Applications include creating custom electronics housings, automotive prototypes, medical device components, and consumer product iterations. The ability to efficiently produce these small batches allows businesses to test new designs, adapt to changing market demands, and minimize inventory costs.

Material Selection

Types of Plastics

Choosing the right plastic material is essential to ensure the final product performs as required. Different plastics offer various benefits depending on the specific needs of the part. Common plastics used for short run parts include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its durability, strength, and impact resistance, ABS is commonly used in automotive parts, electronic enclosures, and toys.

- Polycarbonate (PC): This plastic has high transparency, impact resistance, and heat resistance. It is often used in safety glasses, medical devices, and compact discs.

- Nylon (PA): Valued for its high strength, durability, and wear resistance, Nylon is used in gears, bearings, and other mechanical components.

- PEEK (Polyether Ether Ketone): A high-performance thermoplastic that excels in extreme conditions. PEEK is used in aerospace, medical implants, and industrial applications due to its chemical resistance and thermal stability.

- PLA (Polylactic Acid): A biodegradable and eco-friendly material often used in 3D printing due to its ease of use and availability in various colors.

Material Properties

When selecting a plastic material for short run manufacturing, it’s crucial to consider the following properties:

- Mechanical Strength: The material's ability to withstand stress without breaking or deforming.

- Thermal Stability: The material's ability to maintain its properties at high or low temperatures.

- Chemical Resistance: The material’s resistance to damage from exposure to chemicals.

- Moldability: How easily the material can be molded or shaped into the desired form.

- Cost: Including both the raw material and processing expenses.

Rapid Prototyping Technologies

3D Printing

3D printing, or additive manufacturing, is a key method for producing short run plastic parts. It enables the creation of complex geometries that may be challenging to achieve with traditional manufacturing methods. Different 3D printing technologies include:

- Fused Deposition Modeling (FDM): A widely used and cost-effective method that extrudes melted plastic, layer by layer. FDM is ideal for prototypes and low-cost production.

- Stereolithography (SLA): Uses a laser to cure liquid resin into solid layers. SLA offers high-resolution and smooth surface finishes, making it suitable for intricate designs and small batches.

- Selective Laser Sintering (SLS): Uses a laser to sinter powdered material into solid structures, ideal for producing functional prototypes or small batches of end-use parts.

Injection Molding

Injection molding is a common and reliable process for manufacturing plastic parts, even in small quantities. In this method, molten plastic is injected into a mold under high pressure. Rapid injection molding techniques are commonly used for short runs to reduce costs and lead times:

- Hot Runner Systems: These systems recycle the heating element used in the molding process, which minimizes material waste and lowers production costs.

- Prototype Molds: Simple molds specifically designed for short runs help reduce costs compared to the full-scale molds used in mass production.

- Small-Scale Injection Molding Machines: These machines are designed to produce small batches of plastic parts without requiring large, expensive equipment.

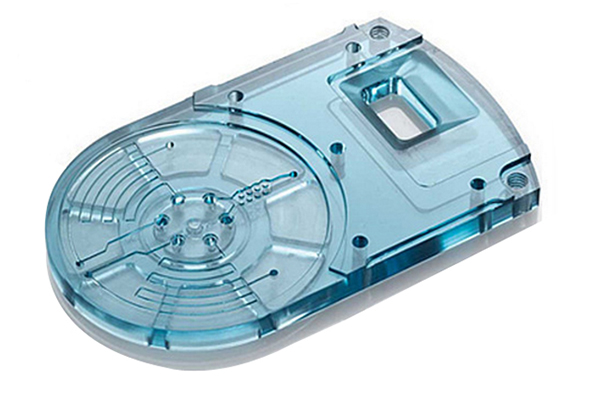

CNC Machining

CNC (Computer Numerical Control) machining is another effective method for producing short run plastic parts. It involves the use of computer-controlled machines to cut and shape plastic materials with high precision. Common CNC processes include:

- Milling: A rotating cutter removes material to shape the part.

- Turning: The plastic material is rotated while a fixed cutting tool shapes it into cylindrical parts.

- Drilling: Specialized drill bits create holes in the material for assembly or other purposes.

Conclusion

Summary of Best Practices

To efficiently manufacture short run plastic parts, follow these best practices:

- Material Selection: Choose the right plastic material based on the specific application, considering factors such as mechanical properties, thermal stability, and moldability.

- Leverage Rapid Prototyping: Utilize 3D printing, injection molding, and CNC machining to quickly produce parts, ensuring quality and reducing lead times.

- Ensure Quality Control: Implement robust quality control measures throughout production to maintain consistency and avoid defects.

- Optimize Processes: Streamline the production process by adopting cost-effective methods like hot runner systems, prototype molds, or small-scale injection molding machines.

Future Trends in Short Run Plastic Part Manufacturing

As technology advances, several trends will shape the future of short run plastic part manufacturing:

- Advancements in Additive Manufacturing: Emerging 3D printing technologies will offer faster production speeds, improved resolution, and a broader range of materials.

- Hybrid Manufacturing: Combining additive (3D printing) and subtractive (CNC machining) processes to take advantage of both methods’ strengths, offering more versatility and efficiency.

- Automation and AI Integration: Automation and artificial intelligence will help optimize manufacturing workflows, improve precision, reduce errors, and enhance productivity.

- Sustainable Manufacturing: Increased focus on using eco-friendly materials, reducing waste, and adopting energy-efficient production processes will lead to greener manufacturing practices.

FAQs

What Are the Advantages of Using Rapid Prototyping for Short Run Plastic Parts?

Rapid prototyping offers significant advantages, including reduced lead times, cost savings, and the ability to produce complex geometries. It enables businesses to test and refine designs quickly, which is crucial for fast-paced industries, allowing products to reach the market faster and meet evolving customer demands.

How Can I Ensure the Quality of My Short Run Plastic Parts?

Ensuring the quality of short run plastic parts involves rigorous testing and inspection at various stages of production. Use precise measurement tools, conduct visual inspections, and adhere to industry standards and specifications. Collaborating with experienced manufacturers and maintaining strong quality control processes will help ensure consistency and product excellence.

What Are Some Cost-Effective Methods for Producing Short Run Plastic Parts?

To reduce costs, consider using techniques like rapid injection molding, hot runner systems, small-scale injection molding machines, and 3D printing technologies like FDM and SLA. Additionally, optimizing designs to minimize material waste and manufacturing time can also contribute to cost savings.