Selecting the right 2K Injection Molding Supplier is a critical decision that goes far beyond standard procurement. Two-shot (or multi-component) molding is a complex process where two different thermoplastics are injected into a single mold to create a bonded, monolithic part. It demands an exceptional blend of specialized machine technology, advanced mold engineering, deep material science, and precise process control. Choosing a supplier who lacks this integrated expertise can result in poor part quality, delamination, extended development times, and financial losses. This guide provides engineers, product developers, and procurement specialists with a rigorous framework to identify and qualify a truly capable 2K Injection Molding Supplier, ensuring your project for soft-touch grips, sealed assemblies, or multi-colored parts is executed flawlessly from the first shot.

What Is 2K Injection Molding and Why Does Supplier Choice Matter?

2K Injection Molding is a manufacturing process where two separate materials are sequentially or simultaneously injected into a mold to form a single, integrated component. Common applications include soft-touch overmolding on rigid substrates (toothbrush handles, tool grips), creating sealed assemblies (gaskets molded onto housings), and producing two-color parts without assembly.

The supplier choice is paramount because:

- Irreversible Bonding: The materials must bond chemically or mechanically in the mold. A supplier without proper material compatibility knowledge will produce parts that delaminate.

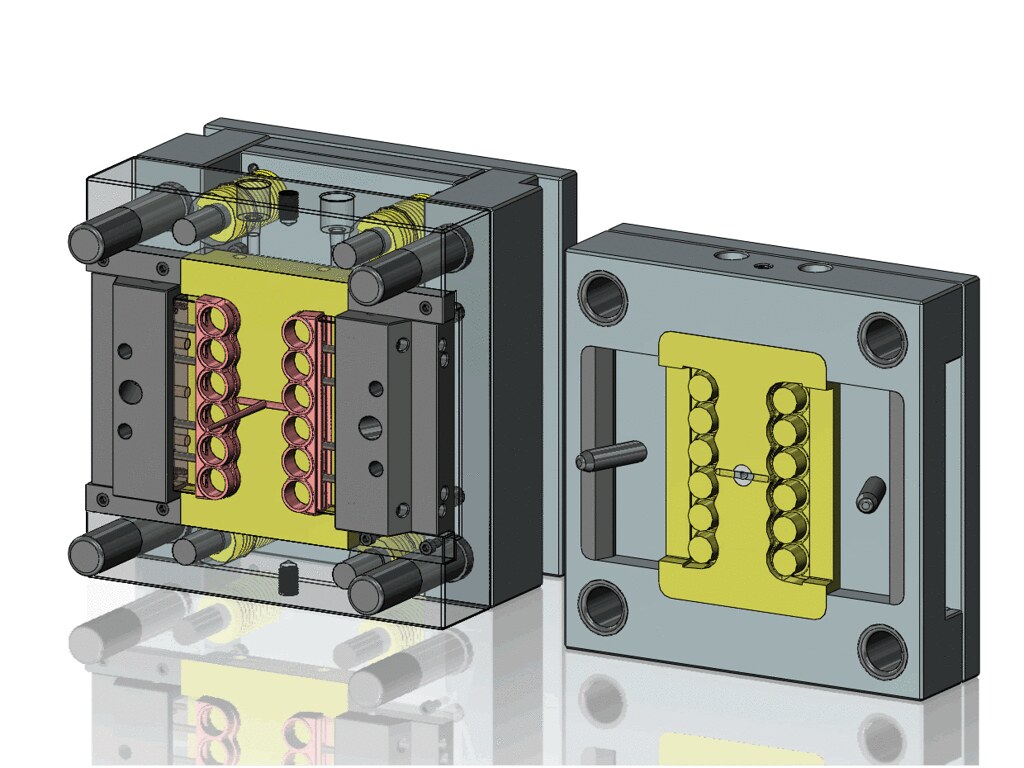

- Complex Tooling: 2K molds are significantly more complex, often requiring rotating platens, indexable cores, or core-back sequences. Mold design and build expertise is non-negotiable.

- Precision Process Control: Timing, temperature, and pressure control for two different materials must be synchronized perfectly. Inadequate control leads to short shots, flashes, or weak bonds.

Which Certifications (ISO 9001, IATF 16949, ISO 13485) Should a 2K Supplier Hold?

Certifications are your first filter for systemic quality. The required certification depends on your industry.

- ISO 9001: The baseline Quality Management System. It shows the supplier has structured processes.

- IATF 16949: Essential for automotive components. It mandates rigorous process control, risk management, and defect prevention—critical for high-reliability 2K parts like seals or switches.

- ISO 13485: Mandatory for medical devices. It focuses on risk management, traceability, and validation, which is vital for 2K medical parts where failure (delamination) is unacceptable.

- Verify the Scope: Ensure the certificate explicitly covers injection molding and mold manufacturing.

How to Verify Proven Experience in Two-Shot or Multi-Component Molds?

Ask for tangible proof, not just claims.

- Request Case Studies: Ask for detailed examples of past 2K projects. Look for complexity similar to yours (e.g., a rotating mold for a two-color part, an overmold on a complex substrate).

- Ask for Physical Samples: A capable supplier should be able to provide physical samples from previous jobs. Examine the bond line quality, flash, and cosmetic appearance.

- Inquire About Failure Modes: Ask, "What is the most common bonding failure you've encountered, and how did you solve it?" An experienced supplier will have specific answers about adhesion promoters, process windows, or gate design.

What Machine Capabilities (Rotary Platen, Indexing, Core-Back) Must the Supplier Own?

The machine configuration dictates the molding sequence. Ensure they have the right technology for your design.

- Rotary Platen Machines: The most common setup. The mold core rotates 180° on a horizontal axis between shots. Ideal for two-shot parts where the substrate is fully overmolded.

- Indexing/Shuttle Table Machines: The core or mold half moves linearly or rotates on a vertical axis to different injection stations. Offers flexibility for multi-shot or insert molding.

- Core-Back Technology: Uses movable mold sections to create space for the second shot. Used for complex geometries where a rotating mold isn't feasible.

- Key Feature: The machines must have two (or more) independent injection units, each with precise temperature and pressure control for different materials.

How to Evaluate In-House Mold Design and Build Expertise for 2K Tools?

This is arguably the most critical factor. Outsourcing 2K mold design is a major risk.

- Insist on In-House Expertise: The mold designer must work hand-in-hand with the process engineers. Ask to meet the design team and review a Design for Manufacturability (DFM) report for a past 2K project. It should detail gate locations for each material, rotation/action sequences, cooling for both materials, and venting strategies.

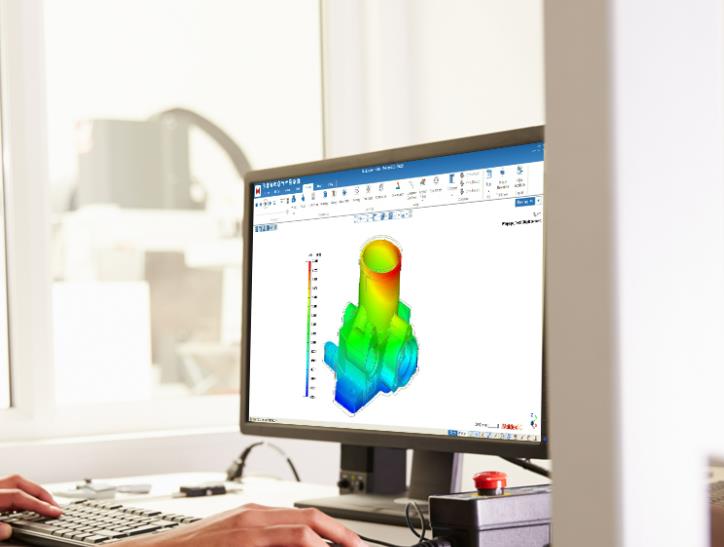

- Mold Flow Analysis: They should perform dual-material mold flow analysis to predict weld lines, filling patterns, and potential bonding issues before steel is cut.

- Probe Their Problem-Solving: Ask, "How do you ensure perfect alignment between the first and second shot cavities after rotation?" A strong answer involves details about interlocks, guiding systems, and machining tolerances.

What Material Selection Support (Bonding Charts, Rheology Data) Should You Expect?

A true partner guides you to a successful material marriage.

- Adhesion/Bonding Charts: They should provide data or have access to material supplier databases showing proven bonding pairs (e.g., PC/ABS to TPU, PP to TPE). For non-bonding pairs, they must recommend and have experience with compatibilizers or mechanical interlocks.

- Processing Window Alignment: They should advise on selecting materials with compatible melting temperatures and shrinkage rates to prevent warpage or stress at the bond line.

- Regulatory Knowledge: For regulated industries, they must ensure both materials meet the necessary standards (e.g., USP Class VI, UL94, FDA).

How to Assess Process Control Systems for Shot-to-Shot Repeatability?

Precision is everything. Inquire about their approach to scientific molding.

- Cavity Pressure Sensing: The use of cavity pressure transducers is a strong indicator. It allows them to monitor and control the packing phase of both materials in real-time, which is critical for bond strength and dimensional consistency.

- Process Validation Data: They should be able to explain how they document and validate the process (e.g., using Process Capability Studies - Cp/Cpk) for critical dimensions.

- Automation Integration: Look for robotic part handling to ensure consistent cycle times and minimize human error, which is crucial for 2K process stability.

How to Compare Lead Times for Tool Build and Process Validation?

2K projects have longer, more complex development phases. Get detailed schedules.

- Phased Timeline: A realistic quote should separate:

- Design & DFM: 2-4 weeks.

- Mold Manufacturing: 16-24+ weeks for a complex 2K production mold.

- Sampling & Process Development: 4-6 weeks. This phase is longer as they must fine-tune temperatures, timings, and rotations to achieve perfect bonding.

- Validation & PPAP: 2-4 weeks.

- Ask: "What is the typical iteration cycle for tuning a 2K mold after the first sample?" Their answer will reveal their efficiency and experience.

What Cost Transparency Is Needed in 2K Quotes (Tool, Machine Time, Scrap)?

A transparent quote prevents hidden costs.

- Detailed Tooling Cost Breakdown: Should include costs for each mold half, the rotation/indexing mechanism, and any special actions.

- Machine Hourly Rate Justification: 2K machines often have a premium rate. Understand the basis for it.

- Scrap Rate Assumptions: The startup and process tuning for 2K molding generates higher initial scrap. The quote should state the assumed scrap rate for production and who bears the cost of development scrap.

- Cost Drivers Table:

Cost Component Why It's Higher in 2K What to Look For in Quote

Mold Cost Complexity (rotary mechanism, multiple cores/cavities, tighter tolerances). Line-item breakdown.

Machine Time Two injection units, longer cycle times, specialized presses. Clear hourly rate and cycle time estimate.

Material Cost Potential for more expensive engineering resins or bonding agents. Material prices quoted separately.

Development Extensive process tuning and validation. Is process development a separate line item or included?

Conclusion

Choosing a reliable 2K Injection Molding Supplier is an exercise in due diligence that must probe deep into technical integration. The ideal partner is not just a molder but an engineered solutions provider with in-house mastery over the triumvirate of specialized machinery, complex mold design, and material science. They operate with certified systems, embrace scientific process control, and communicate with full transparency. By using this guide to evaluate potential suppliers against these stringent criteria, you significantly de-risk your project, ensuring that your innovative 2K product is realized with the quality, reliability, and performance it was designed to achieve.

FAQ on Choosing a 2K Injection Molding Supplier

What's the difference between 2K molding and insert/overmolding?

2K Molding creates a part from two different plastics in one continuous cycle in a single, complex mold. Insert Molding involves placing a pre-made insert (metal, plastic, electronic) into a mold and then overmolding plastic around it. The machinery and tooling requirements differ.

Can any injection molding supplier do 2K work?

No. 2K requires specialized machines with multiple injection units and specific mold motion capabilities (rotation, indexing). More importantly, it requires deep, integrated expertise in designing for and processing two materials simultaneously. A standard molder will likely fail.

How do I verify the bond strength between the two materials?

A qualified supplier should have a testing protocol, which may include cross-sectioning and microscopic analysis, peel tests (e.g., ASTM D6862), or tensile bond tests. This data should be part of the initial material validation and production part approval process (PPAP).

What are the most common reasons for 2K molding failure?

- Poor Material Adhesion: Choosing incompatible materials without proper bonding agents.

- Improper Mold Design: Incorrect gating, insufficient venting, or misalignment between first and second shot cavities.

- Process Control Errors: Incorrect temperature settings for either material or mistimed rotation/injection sequences.

Is prototyping available before committing to a full 2K mold?

Yes, experienced suppliers offer options. These can include using a modular or "cube" mold system for low-volume sampling, building a single-cavity prototype mold, or even sequential molding on a standard press (much slower, but viable for proof-of-concept).

Contact Yigu technology for custom manufacturing.

At Yigu Technology, we are engineered to be your reliable 2K Injection Molding Supplier. Our integrated approach combines IATF 16949 certified processes, a dedicated fleet of rotary platen and indexing 2K machines, and full in-house mold design and build expertise focused on multi-component solutions. From initial material bonding consultancy to scientific process validation, we manage the complete complexity so you can launch innovative, high-quality 2K products with confidence.

If your project demands a partner with proven 2K mastery, let's connect.

Contact Yigu Technology today for a technical consultation and review of our 2K molding portfolio and capabilities.