In the modern manufacturing industry, the injection molding process plays a crucial role. However, with the increasing emphasis on environmental protection, green injection molding has become an essential trend. Here are 10 strategies to effectively green the injection molding process.

10 Strategies for Green Injection Molding

1. Material Selection

Choosing environmentally friendly materials is the foundation of green injection molding. Biodegradable plastics, such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and polybutylene adipate terephthalate (PBAT), are excellent alternatives to traditional plastics. For example, PLA is made from renewable resources like corn starch or sugarcane. It has a relatively short degradation time of several months to a few years in the right environment, while traditional plastics like polyethylene (PE) and polypropylene (PP) can take hundreds of years to degrade.

In terms of energy consumption, the production of biodegradable plastics generally requires less energy. Studies have shown that the energy consumption for producing PLA is about 25 - 55% lower than that of traditional plastics. This not only reduces the carbon footprint but also saves energy resources.

2. Optimize Mold Design

An optimized mold design can significantly reduce material waste and shorten the 成型周期. For instance, using conformal cooling channels in the mold can ensure more uniform cooling of the plastic parts. This reduces the cooling time, which in turn shortens the overall molding cycle. A study found that molds with conformal cooling can reduce the cooling time by up to 30 - 50%.

Moreover, an efficient mold design can minimize the amount of excess material. For example, a well - designed gating system can precisely control the flow of plastic into the mold cavity, reducing the formation of runners and sprues that are usually discarded as waste. Some advanced mold designs can reduce material waste by 10 - 20% compared to traditional designs.

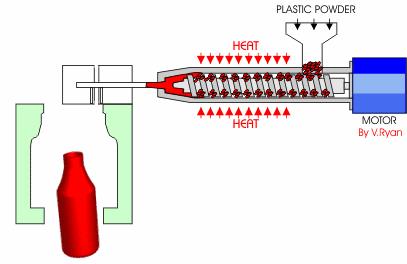

3. Energy - Efficient Equipment

New - generation injection molding machines are designed with energy - saving features. For example, some modern injection molding machines use servo - hydraulic systems. These systems can adjust the pump's output according to the actual power requirements during different stages of the injection process, such as injection, holding pressure, and cooling.

Compared with traditional hydraulic injection molding machines, servo - hydraulic injection molding machines can save 30 - 70% of energy consumption. Another example is the use of electric injection molding machines, which are even more energy - efficient. They eliminate the energy losses associated with hydraulic oil circulation and heat generation, and can achieve an energy - saving rate of up to 80% in some cases.

4. Process Parameter Optimization

Optimizing process parameters like injection pressure, temperature, and injection speed can greatly improve energy efficiency. For example, by precisely adjusting the injection pressure, we can ensure that the plastic material fills the mold cavity completely without using excessive pressure. High - pressure injection not only consumes more energy but also may cause material degradation and product quality problems.

Studies have shown that after optimizing the injection pressure, the energy consumption can be reduced by 10 - 20%. Similarly, controlling the injection temperature accurately can prevent over - heating or under - heating of the plastic material. An optimized temperature setting can improve the fluidity of the plastic, reduce the energy required for injection, and also enhance product quality. After temperature optimization, the energy consumption can be decreased by about 5 - 15%, and the product defect rate can be reduced by 20 - 30%.

5. Recycling and Reusing

Recycling and reusing the waste materials generated during the injection molding process, such as scrap plastic and runner materials, can bring multiple benefits. First, it reduces the amount of waste sent to landfills or incinerators, thus minimizing environmental pollution. Second, it can significantly cut down production costs.

For example, a company that recycles its own scrap plastic can save up to 30 - 50% on raw material costs. The recycling process usually involves shredding, cleaning, and re - granulating the waste plastic, which can then be mixed with virgin plastic materials in a certain proportion for reuse in the injection molding process.

6. Water Management

In the injection molding process, water is mainly used for cooling. Implementing effective water - saving measures in the cooling system can reduce water consumption. For example, using closed - loop cooling systems can recycle and reuse the cooling water. In a closed - loop system, the warm cooling water is cooled down through a heat exchanger and then returned to the cooling process, reducing the need for fresh water intake.

Compared with open - loop cooling systems, closed - loop cooling systems can save 50 - 80% of water consumption. Additionally, installing water - flow control valves and sensors can precisely monitor and adjust the water flow rate according to the actual cooling requirements, further optimizing water usage.

7. Waste Reduction

Reducing the generation of defective products is an important aspect of green injection molding. One way to achieve this is by improving product design accuracy. Using computer - aided design (CAD) and computer - aided engineering (CAE) software, designers can simulate the injection molding process in advance, predict potential problems such as warping, shrinkage, and air traps, and then optimize the product design accordingly.

For example, a company that used CAE software to optimize its product design reduced its defect rate from 10% to 3 - 5%. Regular equipment maintenance and calibration can also ensure the stability of the injection molding process, reducing the occurrence of defects caused by equipment malfunctions.

8. Green Packaging

Selecting green packaging materials and designing simple and practical packaging can reduce the environmental impact of the final product. For example, using biodegradable or recycled packaging materials instead of traditional non - biodegradable plastics. Biodegradable packaging materials can decompose naturally in the environment, reducing plastic waste.

Moreover, designing minimalist packaging can reduce the amount of packaging material used. A study showed that reducing the packaging volume by 20 - 30% can significantly cut down the environmental footprint associated with packaging production and disposal.

9. Employee Training

Training employees on green injection molding concepts and proper operation methods is crucial. Well - trained employees are more likely to follow green practices in daily work. For example, they can better control the injection molding process to avoid waste and energy waste.

After employee training, a company found that the number of environmental - friendly behavior initiatives increased by 30 - 50%, such as proper material handling to reduce waste and energy - saving operation habits. At the same time, the production efficiency also improved by 10 - 20% due to more skilled operation.

10. Continuous Monitoring and Improvement

Establishing a mechanism for continuous monitoring of the production process and continuous improvement is essential for long - term green injection molding. By installing sensors and monitoring systems, manufacturers can collect real - time data on energy consumption, material usage, and product quality.

For example, a company that monitored its energy consumption found that the energy consumption of a certain injection molding machine was higher than normal. After investigation, it was found that the hydraulic oil had deteriorated, affecting the energy efficiency of the machine. After replacing the hydraulic oil, the energy consumption decreased by 15 - 20%. Regularly analyzing this data can help identify areas for improvement and implement corresponding measures to continuously optimize the green injection molding process.

Yigu Technology, as a non - standard plastic metal products custom supplier, believes that green injection molding is not only an environmental responsibility but also a key to enhancing competitiveness. By adopting the above - mentioned strategies, we can achieve a win - win situation of environmental protection and cost - effectiveness. We are committed to continuously exploring and applying new green technologies in our production process to provide more sustainable products and services to our customers.

FAQ

1. What are the most common biodegradable plastics used in injection molding?

The most common biodegradable plastics used in injection molding are polylactic acid (PLA), polyhydroxyalkanoates (PHA), and polybutylene adipate terephthalate (PBAT). PLA is made from renewable resources like corn starch or sugarcane, PHA is produced by microorganisms, and PBAT is a copolymer with good flexibility and processability.

2. How can I determine if my mold design needs improvement for green injection molding?

If you notice long cooling times, high material waste in the form of runners and sprues, or inconsistent product quality, your mold design may need improvement. You can also use simulation software like CAD and CAE to analyze the mold design and identify areas for optimization.

3. Is it expensive to upgrade to energy - efficient injection molding equipment?

Although the initial investment in energy - efficient injection molding equipment may be higher than traditional equipment, the long - term savings in energy costs can quickly offset this cost. In addition, some regions offer subsidies or incentives for the purchase of energy - efficient equipment, making the upgrade more affordable.

Yigu Technology's View

Yigu Technology, as a non - standard plastic metal products custom supplier, firmly believes that green injection molding is not only an environmental imperative but also a strategic move to enhance our competitiveness. By implementing the strategies mentioned above, we aim to achieve a win - win situation for environmental protection and cost - effectiveness.

We are committed to exploring and applying new green technologies continuously. For example, we actively research and use advanced biodegradable materials to replace traditional plastics in our production. In mold design, we employ the latest CAD and CAE technologies to optimize the design, reducing material waste and production time.

Moreover, we have upgraded our injection molding equipment to the most energy - efficient models available in the market. This not only helps us save energy but also enables us to produce high - quality products more efficiently. We also focus on employee training, ensuring that every team member understands the importance of green injection molding and can implement relevant practices in their daily work. Through these efforts, we hope to provide more sustainable products and services to our customers while minimizing our environmental footprint.

Conclusion

In summary, these 10 strategies for green injection molding - material selection, mold design optimization, using energy - efficient equipment, process parameter optimization, recycling and reusing, water management, waste reduction, green packaging, employee training, and continuous monitoring and improvement - offer a comprehensive approach to making the injection molding process more sustainable.

The use of biodegradable materials can reduce the environmental impact of plastic waste, while optimized mold design and process parameters can lead to significant energy savings and waste reduction. Recycling and reusing waste materials not only cut down on production costs but also minimize waste sent to landfills. Water - saving measures in the cooling system, reducing product defects, and using green packaging are all crucial steps towards a more sustainable production process. Employee training helps to ensure that these strategies are effectively implemented on the ground, and continuous monitoring and improvement allow for long - term optimization of the green injection molding process.

By adopting these green injection molding strategies, manufacturers can contribute to environmental protection while also enhancing their competitiveness in the market. It is a win - win situation that not only benefits the planet but also the bottom line of the business. We encourage all those involved in the injection molding industry to take these strategies seriously and start implementing them in their production processes as soon as possible. Let's work together to create a more sustainable future for the injection molding industry and the environment.