What is Injection Processing Molding

Injection Processing Molding, often simply referred to as injection molding, is a manufacturing process that has been a cornerstone of the production industry for decades. The process involves forcing molten material, typically plastic or metal, into a mold cavity. Once the material fills the cavity, it cools and solidifies, taking on the shape of the mold. This method is highly versatile and can produce a vast range of products, from tiny plastic components to large automotive parts.

The Injection Molding Process in Detail

- Material Preparation: The process begins with the selection of the raw material. For plastic injection molding, pellets of plastic are the most common starting point. These pellets are fed into a hopper, which then delivers them to the injection unit. The material is chosen based on the desired properties of the final product, such as strength, flexibility, heat resistance, and chemical resistance. For Yigu Technology example, if you're manufacturing a food container, you might choose a food - grade plastic like polypropylene (PP) due to its non - toxicity and good chemical resistance.

- Plasticization: In the injection unit, the plastic pellets are melted. This is usually achieved through a combination of heat and mechanical shear. A heated barrel and a rotating screw work together to melt the plastic. The heat softens the plastic, and the screw's rotation further mixes and homogenizes the molten material. The temperature of the barrel is carefully controlled. For instance, for polyethylene (PE), the barrel temperature might be set between 150 - 250°C, depending on the specific grade of PE.

- Injection: Once the plastic is fully melted and homogenized, it's ready to be injected into the mold. A high - pressure piston or the screw itself forces the molten plastic through a nozzle and into the mold cavity. The injection pressure can vary widely, typically ranging from 500 - 2000 bar, depending on the complexity of the mold and the material being used. For a simple, low - viscosity plastic and a straightforward mold, a lower pressure might be sufficient, while a complex, thin - walled part might require a much higher injection pressure.

- Cooling: After the mold cavity is filled, the plastic needs to cool and solidify. This is where the mold's cooling system comes into play. Most molds have channels through which a coolant, usually water, circulates. The cooling time is crucial as it affects the cycle time of the injection molding process. Faster cooling can increase production speed, but it might also lead to internal stresses in the part. For a small plastic toy, the cooling time could be as short as 10 - 20 seconds, while for a large, thick - walled automotive component, it could be several minutes.

- Ejection: Once the plastic has cooled and solidified enough, the mold opens, and the finished part is ejected. Ejection pins, which are located within the mold, push the part out of the cavity. The part may still have some residual stresses at this point, and in some cases, post - processing steps like annealing may be required to relieve these stresses.

The Process of Injection Processing Molding

1. Pre - processing Preparation

Before the actual injection molding process begins, several crucial pre - processing steps are essential. One of the first steps is raw material pretreatment. For Yigu Technology example, if the material is hygroscopic, like some grades of nylon, it must be dried thoroughly. Moisture in the plastic can cause defects such as voids, bubbles, or surface blisters in the final product. Typically, plastics are dried in a hopper dryer at specific temperatures and for a set period. For nylon 6, it might be dried at around 80 - 100°C for 2 - 4 hours.

Cleaning the machine barrel is also vital. Residual materials from previous production runs can contaminate the new material and affect the quality of the current batch. This is especially true when switching between different types of plastics or colors. A purging compound may be used to clean the barrel thoroughly. The barrel cleaning process can take anywhere from 15 - 30 minutes, depending on the size of the barrel and the complexity of the residue.

If the injection - molded part contains metal inserts, they need to be pre - heated. Pre - heating the inserts helps to reduce the thermal stress between the insert and the plastic when the molten plastic is injected around it. This, in turn, prevents cracking or warping of the final product. Inserts are usually pre - heated in an oven to a temperature close to the mold temperature, often in the range of 80 - 120°C.

2. The Core Injection Process

The injection process itself can be broken down into several distinct stages:

- Feeding: In this initial stage, the raw material, usually in the form of pellets, is fed into the hopper of the injection molding machine. The feeding rate needs to be consistent to ensure a continuous supply of material for the subsequent processes. Most injection molding machines have automatic feeding systems that can be adjusted based on the size and type of the product being produced. For a small - scale production of plastic toys, the feeding rate might be set to deliver a specific volume of pellets per minute, say 5 - 10 cubic centimeters per minute.

- Plasticization: Once in the machine, the pellets enter the heated barrel. Here, a combination of heat and mechanical action (from a rotating screw) melts and homogenizes the plastic. The temperature of the barrel is carefully controlled in different zones. For Yigu Technology example, in a three - zone barrel for processing polyethylene, the rear zone might be set at 150 - 170°C, the middle zone at 170 - 190°C, and the front zone at 190 - 210°C. The screw's rotation not only helps in melting the plastic but also in conveying it forward for injection.

- Injection: The molten plastic is then forced through a nozzle and into the mold cavity under high pressure. The injection pressure is a critical parameter. As mentioned earlier, it can range from 500 - 2000 bar. For a large, thick - walled automotive part, a higher injection pressure might be required to ensure complete filling of the mold cavity. The injection speed also plays a role; a faster injection speed can be used for simple parts, while a slower speed might be necessary for complex geometries to prevent air entrapment or jetting.

- Cooling: After the mold is filled, the plastic needs to cool and solidify. The cooling time is influenced by factors such as the thickness of the part, the material used, and the mold design. A thin - walled plastic container might cool in as little as 5 - 10 seconds, while a thick - walled industrial component could take several minutes. The mold's cooling system, usually a network of water - filled channels, helps to dissipate the heat and speed up the cooling process.

- Ejection: Once the plastic has cooled sufficiently, the mold opens, and the finished part is ejected using ejection pins. The ejection force needs to be carefully calibrated to avoid damaging the part. If the force is too low, the part may not be ejected properly, while if it's too high, it can cause the part to warp or break.

3. Post - processing Steps

After the part is ejected from the mold, post - processing steps are often necessary:

- Annealing: Annealing is a heat - treatment process that helps to relieve internal stresses in the part. These stresses can be caused by uneven cooling during the injection molding process. By heating the part to a specific temperature (below its melting point) and then slowly cooling it, the molecular structure of the plastic can relax, reducing the risk of cracking or warping over time. For example, for a polycarbonate part, it might be annealed at around 120 - 140°C for 30 - 60 minutes.

- Humidifying: Humidifying, also known as moisture conditioning, is mainly used for some hygroscopic plastics like nylon. These plastics can absorb moisture from the environment, which can affect their mechanical properties and dimensional stability. By exposing the parts to a controlled humidity environment, they can reach a moisture equilibrium more quickly. For nylon parts, they might be placed in a chamber with a relative humidity of 50 - 60% for 24 - 48 hours.

Applications of Injection Processing Molding in Different Industries

Injection processing molding has found its way into a vast number of industries, playing a crucial role in the production of a wide range of products. Its versatility, precision, and cost - effectiveness make it an ideal manufacturing process for diverse applications.

1. Consumer Electronics

In the consumer electronics industry, injection processing molding is everywhere. For Yigu Technology example, mobile phone cases are almost exclusively made using this process. The ability to create complex shapes with high precision allows manufacturers to design cases that fit the phone perfectly while also incorporating features like shock - absorption and stylish designs. A study by a leading market research firm shows that over 90% of mobile phone cases globally are produced through injection molding.

Computer accessories such as keyboards, mouse housings, and laptop casings also rely heavily on injection molding. The process enables the production of lightweight yet durable components. For instance, the keys on a computer keyboard are often made from plastic using injection molding, with tight tolerances to ensure smooth keystrokes. The use of injection molding in consumer electronics has significantly contributed to the miniaturization and cost - reduction of these products, making them more accessible to consumers. It has also allowed for faster production cycles, keeping up with the high - demand and rapidly evolving nature of the consumer electronics market.

2. Automotive Industry

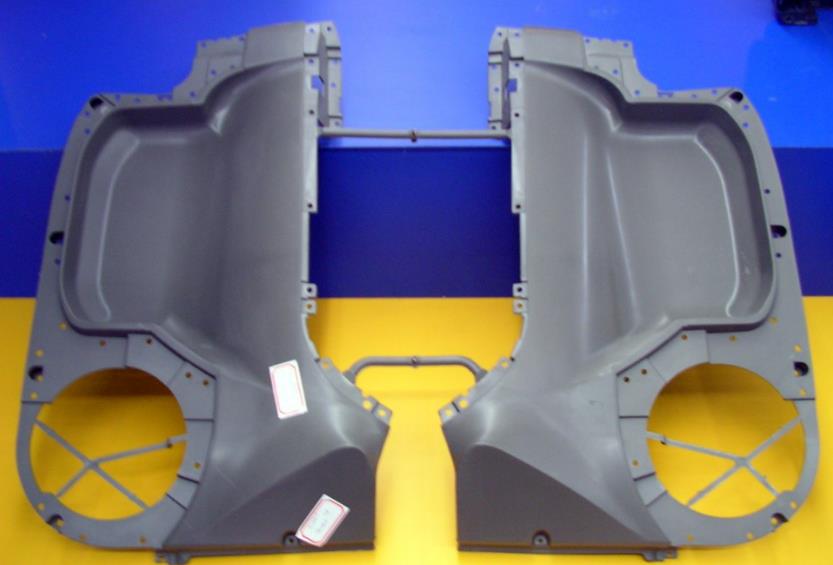

In the automotive industry, injection processing molding is used to manufacture a variety of components. Dashboard components are commonly produced through injection molding. The large, complex shapes of dashboards require a manufacturing process that can handle such geometries with precision. Injection molding allows for the integration of features like air vents, instrument clusters, and storage compartments into a single piece, reducing assembly time and costs.

Headlamp and taillight housings are also made using this process. These parts need to be not only lightweight but also highly durable to withstand various environmental conditions. Injection - molded plastic housings provide the necessary strength while also being cost - effective compared to other manufacturing methods. According to industry statistics, injection - molded plastic components account for approximately 50 - 60% of the total weight of a modern vehicle's interior components. This high percentage highlights the importance of injection molding in the automotive industry, as it helps automakers meet strict weight - reduction and cost - efficiency targets without sacrificing quality or safety.

3. Medical Equipment

In the medical equipment field, injection processing molding is used to produce a wide range of items. Syringes are a prime example. The high - precision requirements of syringes, such as accurate volume measurement and smooth plunger movement, can be achieved through injection molding. The process allows for the use of medical - grade plastics that are biocompatible and meet strict regulatory standards.

Medical instrument housings also benefit from injection molding. These housings need to protect the sensitive internal components while also being easy to clean and sterilize. Injection - molded plastics can be designed with smooth surfaces and rounded edges, making them suitable for the sterile environments of hospitals and clinics. The use of injection molding in medical equipment has improved the quality and safety of medical devices. It has also enabled the mass production of high - quality medical products, making healthcare more accessible and affordable.

4. Daily Necessities

In our daily lives, we encounter numerous products made through injection processing molding. Plastic bottle caps are a common example. The process allows for the production of caps with precise threading and sealing mechanisms, ensuring that bottles are properly sealed to prevent leakage. Kitchen utensils such as spoons, forks, and spatulas are also often injection - molded. The ability to use different colors and materials gives these utensils an appealing appearance and functionality.

Toys are another area where injection molding is widely used. The process can create toys with complex shapes and moving parts, providing children with engaging playthings. From action figures to building blocks, injection - molded toys are a staple in the toy industry. In fact, it is estimated that around 80% of plastic toys on the market are produced through injection molding. This shows how integral injection molding is to our daily lives, as it provides us with a wide range of essential and enjoyable products.

FAQs

1. What are the common problems in injection molding and how to solve them?

- Product Surface Defects: One common issue is the appearance of surface blemishes such as sink marks, flow marks, and silver streaks. Sink marks often occur due to uneven cooling or excessive material shrinkage. To solve this, adjusting the cooling system to ensure more uniform cooling, or increasing the holding pressure and time during the injection process can be effective. Flow marks are usually caused by the non - uniform flow of the molten plastic into the mold. This can be addressed by optimizing the gate location, increasing the injection speed, or adjusting the temperature of the plastic and the mold. Silver streaks are typically a result of moisture in the plastic material. Drying the plastic thoroughly before injection, usually in a hopper dryer at the appropriate temperature for the specific plastic type, can eliminate this problem.

- Dimensional Deviations: Parts may not meet the required dimensional specifications. This can be due to factors like incorrect mold design, improper injection pressure, or inconsistent material properties. If the mold design is faulty, it may need to be modified or repaired. Monitoring and controlling the injection pressure accurately, as well as ensuring the material's consistency in terms of melt flow index and shrinkage rate, can help maintain dimensional accuracy. Regular calibration of the injection molding machine and using high - precision measuring tools during production can also reduce dimensional deviations.

2. How to choose the right plastic material for injection molding?

- Based on Product Requirements: First, consider the end - use of the product. For products that will be in contact with food, food - grade plastics like polypropylene (PP) or polyethylene terephthalate (PET) are essential due to their non - toxicity. If the product needs to be flexible, materials such as thermoplastic elastomers (TPEs) can be a good choice. For example, a flexible phone case might use a TPE material to provide shock - absorption and a soft grip.

- Performance Requirements: Evaluate the mechanical, thermal, and chemical properties required. If the product will be exposed to high temperatures, plastics with high heat resistance like polycarbonate (PC) or polyphenylene sulfide (PPS) should be considered. PC has a high glass - transition temperature and is often used in applications like automotive headlamp lenses. For products that need to resist chemicals, materials like polyvinyl chloride (PVC) or fluoropolymers can be suitable. PVC is resistant to many common chemicals and is used in pipes and chemical containers. Also, consider the strength and stiffness requirements. For a structural component in a machine, a high - strength plastic like nylon or acrylonitrile - butadiene - styrene (ABS) might be appropriate. Nylon has good tensile strength and is often used in gears and bearings.