The Step - by - Step Injection Moulding Process

Plastic Material Preparation

The first crucial step in the injection moulding process is plastic material preparation. There are two main types of plastics: thermoplastics and thermosets. Thermoplastics, such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), can be melted and re - solidified multiple times. They have a linear or branched molecular structure. In contrast, thermosets like phenolic resins and epoxy resins, once cured through heat and chemical reactions, cannot be remelted. Their molecular structure forms a cross - linked network during curing.

Before injection, the plastic material often requires some pretreatment. For example, many plastics are hygroscopic and need to be dried to remove moisture. Excess moisture can cause defects in the final product, such as bubbles or surface imperfections. The drying temperature and time vary depending on the type of plastic. Nylon, for instance, may need to be dried at around 80 - 110°C for several hours.

Colorants may also be added during this stage. These can be in the form of masterbatches (concentrated color - pigmented plastic pellets) or liquid colorants. The amount of colorant added is carefully calculated based on the desired final color, as too much or too little can lead to inconsistent coloring.

Injection

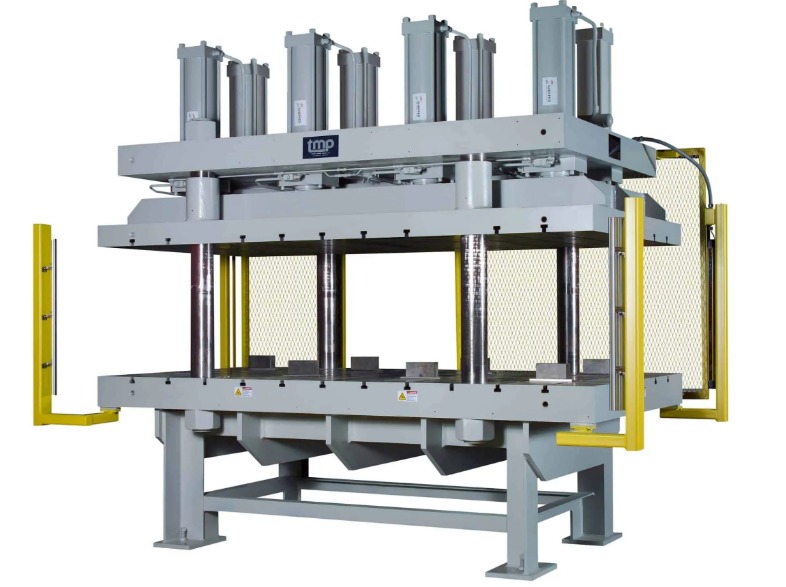

Once the plastic material is properly prepared, it enters the injection phase. The plastic pellets are fed into the hopper of the injection molding machine and then into the heated barrel. Inside the barrel, a rotating screw plays a vital role. As the screw rotates, it not only conveys the plastic pellets forward but also compresses and shears them. This mechanical action, combined with the heat from the barrel heaters, causes the plastic to melt and become a viscous, flowing mass.

The molten plastic is then forced through the nozzle of the injection unit and into the mold cavity. The injection pressure and speed are two critical parameters. High injection pressure is necessary to ensure that the molten plastic fills every intricate detail of the mold cavity, especially for complex - shaped products. However, if the pressure is too high, it can cause problems such as flash (excess plastic squeezing out between the mold halves), over - packing (resulting in high internal stresses in the product), or even damage to the mold.

The injection speed affects the flow pattern of the molten plastic. A slow injection speed may lead to incomplete filling of the mold, especially for products with thin - walled sections. On the other hand, an overly fast injection speed can cause the plastic to jet into the mold cavity, trapping air and creating voids or causing weld lines where different streams of plastic meet. For a typical medium - sized plastic part, the injection speed might be set in the range of 30 - 80 mm/s, while the injection pressure could be anywhere from 50 - 150 MPa, depending on the plastic material and the mold design.

Cooling

After the mold cavity is filled with the molten plastic, the cooling stage begins. This is a crucial step as it determines the quality, dimensional stability, and production cycle time of the final product. The mold is equipped with a cooling system, usually consisting of channels through which a cooling medium (such as water or a heat - transfer oil) circulates.

The cooling medium absorbs the heat from the molten plastic, causing it to solidify and take the shape of the mold cavity. The rate of cooling is not uniform throughout the product. Thicker sections of the product take longer to cool than thinner ones. Uneven cooling can lead to warping, where the product twists or bends out of shape. To minimize warping, the cooling channels in the mold are designed to ensure a more even distribution of cooling. For example, in a plastic bottle mold, the cooling channels are arranged in a spiral pattern around the cavity to promote uniform cooling of the cylindrical shape.

The cooling time is a significant factor in the overall production cycle. A longer cooling time ensures that the product is fully solidified and has better dimensional stability. However, it also increases the production cycle time, reducing productivity. On average, the cooling time can account for 60 - 80% of the total injection molding cycle time. For a small plastic toy, the cooling time might be around 10 - 20 seconds, while for a large automotive component, it could be several minutes.

Ejection

Once the plastic part has cooled and solidified sufficiently, it needs to be removed from the mold. This is accomplished by the ejection system. The ejection system typically consists of ejector pins, which are small rods that are located in strategic positions within the mold. When the mold opens, hydraulic or mechanical force is applied to the ejector pins, causing them to push the plastic part out of the mold cavity.

The location and force of the ejection are critical. If the ejector pins are placed in the wrong position, they can cause the product to crack or deform during ejection. For example, placing an ejector pin too close to a thin - walled section of the product can cause the wall to collapse under the ejection force. The force applied by the ejector pins also needs to be carefully controlled. Too little force may not be enough to eject the product, while too much force can damage the product or the mold. In some cases, additional ejection devices such as air ejection (using compressed air to push the product out) or stripper plates (a flat plate that pushes the product off the mold) may be used, especially for complex - shaped or delicate products.

Advantages of Injection Moulding

Injection moulding is a manufacturing process that offers numerous advantages, making it a popular choice across various industries. Here are some of its key benefits:

- High Production Efficiency:Injection moulding machines can operate at high speeds, with cycle times often ranging from a few seconds to a couple of minutes, depending on the complexity and size of the product. For example, a simple plastic toy part can be produced in as little as 5 - 10 seconds per cycle. This high - speed production enables manufacturers to produce a large number of parts in a relatively short period, increasing productivity significantly. In a typical 8 - hour workday, a well - maintained injection moulding machine can produce thousands of identical parts.

- Complex Shape Fabrication:One of the remarkable features of injection moulding is its ability to create products with intricate shapes and fine details. The molten plastic can flow into every nook and cranny of the mold cavity, allowing for the production of parts with undercuts, thin walls, and complex internal structures. For instance, the production of medical devices often requires components with complex geometries for specific functions. Injection moulding can precisely replicate these designs, ensuring that the final product meets the strict requirements of the medical industry.

- High - Precision Dimensional Accuracy:Injection moulding offers excellent dimensional accuracy. Tolerances can be controlled within very tight limits, usually in the range of ±0.05 - ±0.1 mm for most plastic parts. This high level of accuracy is crucial in industries such as automotive and electronics. In the automotive industry, plastic components need to fit perfectly with other parts of the vehicle to ensure proper functioning and safety. Injection - moulded parts can be produced with such precision that they can be directly assembled without the need for additional machining or adjustment in many cases.

- Suitability for Mass Production:The cost - effectiveness of injection moulding becomes more pronounced with increasing production volume. Although the initial investment in molds and machinery can be high, the cost per unit decreases significantly as the number of parts produced increases. For large - scale production runs of 10,000 units or more, injection moulding often provides the most cost - efficient manufacturing solution compared to other methods like 3D printing or manual assembly. This makes it an ideal choice for consumer goods manufacturers who need to produce millions of units of a product, such as plastic containers or mobile phone cases.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology has in - depth experience in the injection moulding process.

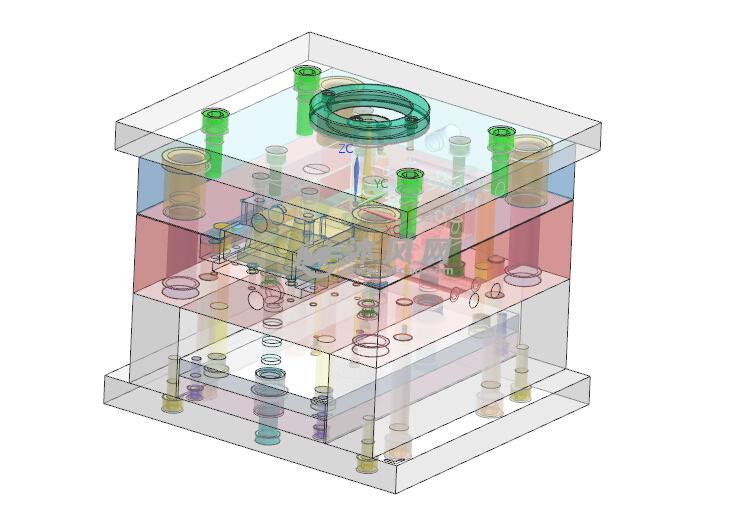

In terms of mold design optimization, our team of experienced engineers uses advanced 3D design software and conducts thorough mold - flow analysis. This allows us to accurately predict the flow of molten plastic in the mold, identify potential issues such as air traps and uneven filling in advance, and make corresponding design adjustments. For example, by optimizing the gate location and size, we can ensure that the plastic fills the mold cavity more evenly, reducing the occurrence of defects.

When it comes to material selection, we consider multiple factors. We take into account the product's application environment, performance requirements (such as strength, heat resistance, and chemical resistance), and cost - effectiveness. Our experts are well - versed in a wide range of plastic materials and can provide professional advice to customers. For instance, if a product needs to withstand high temperatures, we might recommend materials like polyetheretherketone (PEEK); for products requiring high - strength and good wear - resistance, polyamide (PA) could be a suitable choice.

In terms of quality control, Yigu Technology has a strict and comprehensive system. We conduct incoming inspection of raw materials to ensure their quality and compliance. During the injection moulding process, we closely monitor key parameters such as injection pressure, temperature, and cooling time. Regular sampling and inspection of finished products are carried out to check for dimensional accuracy, appearance quality, and mechanical properties. With our professional services and strict quality control, we are committed to providing customers with high - quality non - standard plastic metal products that meet their specific needs.