Introduction

In the vast landscape of modern manufacturing, large part injection molding companies play a pivotal role. They are the unsung heroes behind the creation of numerous essential components that we encounter in our daily lives, from the automotive parts that power our vehicles to the industrial equipment that drives various sectors forward.

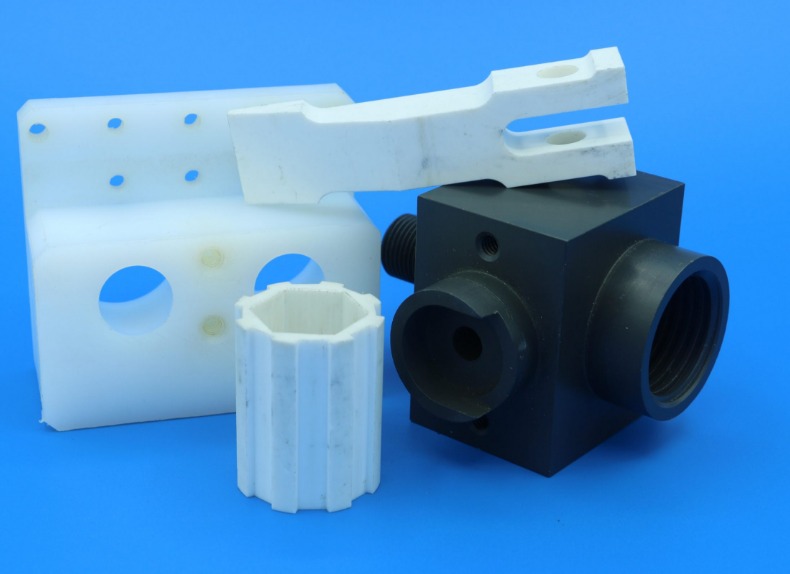

The process of large part injection molding involves injecting molten plastic into a mold cavity under high pressure to create large - scale plastic parts. This technique has revolutionized the manufacturing industry due to its ability to produce parts with high precision, complex geometries, and in large quantities.

The importance of large part injection molding companies cannot be overstated. For one, they contribute significantly to cost - effective production. By mass - producing large parts, they can spread out the initial investment in molds and equipment over a large number of units, reducing the per - unit cost. This makes it possible for industries to offer more affordable products to consumers.

Secondly, these companies are at the forefront of innovation. They are constantly researching and developing new materials and techniques to improve the quality, strength, and durability of the parts they produce. For example, the use of advanced engineering plastics in large part injection molding has led to lighter yet stronger components in the aerospace and automotive industries, enhancing fuel efficiency and performance.

As we embark on this exploration of the world of large part injection molding companies, we will delve into their key players, the technologies they employ, the challenges they face, and the future trends that will shape their growth. Whether you are an engineer looking for a reliable manufacturing partner, a business owner exploring cost - effective production solutions, or simply someone curious about the manufacturing processes that shape our world, this article will provide valuable insights.

The Basics of Large Part Injection Molding

1. The Injection Molding Process

Large part injection molding is a complex and precise manufacturing process. It begins with the careful preparation of raw materials. High - quality plastic pellets are selected based on the specific requirements of the final product. These pellets are then fed into the hopper of the injection molding machine.

The next step is heating and plasticizing. Inside the barrel of the injection molding machine, the plastic pellets are heated by electric heaters. As the temperature rises, the plastic transitions from a solid to a molten, viscous state. The screw inside the barrel rotates, which not only helps in the uniform mixing of the plastic but also generates frictional heat, further aiding the plasticizing process. For example, in the production of large automotive bumpers, polypropylene (PP) pellets are heated to around 180 - 250°C to achieve the desired molten state.

Once the plastic is fully plasticized, it's time for high - pressure injection. A powerful hydraulic system in the injection molding machine exerts high pressure on the screw, forcing the molten plastic through the nozzle and into the mold cavity at a high speed. The injection pressure can range from 50 - 200 MPa, depending on the complexity of the part and the properties of the plastic. This high - pressure injection ensures that the molten plastic fills every intricate detail of the mold cavity accurately.

After the mold cavity is filled, the cooling and solidification stage commences. Cooling channels are integrated into the mold. A coolant, usually water or a specialized heat - transfer fluid, circulates through these channels. As the coolant absorbs the heat from the molten plastic, the plastic gradually cools and solidifies, taking on the shape of the mold cavity. The cooling time is a critical factor, as it affects the production cycle and the quality of the final product. For large parts, the cooling time can range from several minutes to even hours.

Finally, when the plastic part has cooled and solidified sufficiently, the mold opens, and the part is ejected through the use of ejector pins. These pins push the part out of the mold, completing the injection molding process. However, in some cases, the part may require post - processing, such as trimming to remove excess material (flash), sanding for a smooth finish, or painting for aesthetic and protective purposes.

2. Materials Used

Several types of plastics are commonly used in large part injection molding, each with its own set of unique characteristics and suitable applications:

- ABS (Acrylonitrile - Butadiene - Styrene): ABS is a popular choice due to its excellent combination of properties. It has high strength, good impact resistance, and is easy to process. This makes it suitable for a wide range of applications, such as automotive interior components like dashboards and door panels. Its heat - resistance allows it to withstand the normal operating temperatures within a vehicle. ABS also has good dimensional stability, ensuring that the parts maintain their shape over time.

- PP (Polypropylene): PP is a semi - crystalline thermoplastic with a relatively low density, making it lightweight. It has good chemical resistance, which makes it suitable for applications in the chemical and food - packaging industries. For example, large - scale chemical storage tanks and food containers are often made from PP. It also has a high melting point, allowing it to be used in products that may be exposed to moderate heat, like some kitchenware. Additionally, PP has good fatigue resistance, which is beneficial for parts that are subject to repeated stress, such as hinges in plastic furniture.

- PE (Polyethylene): There are different grades of PE, including low - density polyethylene (LDPE) and high - density polyethylene (HDPE). LDPE is known for its flexibility and transparency. It is often used in the production of large - scale plastic films for applications like greenhouse covers and plastic bags. HDPE, on the other hand, has high strength and rigidity. It is commonly used in the manufacturing of large pipes for water and gas distribution, as well as large storage containers due to its durability and chemical resistance.

- PC (Polycarbonate): PC is highly valued for its exceptional impact resistance, high heat resistance, and excellent optical properties. It is used in applications where these properties are crucial, such as in the production of large - scale safety shields, electronic device enclosures, and automotive headlamp lenses. Its ability to withstand high temperatures makes it suitable for parts that may be exposed to heat during operation, and its optical clarity is ideal for applications where transparency is required.

Key Factors to Consider When Choosing a Large Part Injection Molding Company

Selecting the right large part injection molding company is crucial for the success of any manufacturing project. Here are some key factors to keep in mind:

1. Experience and Expertise

Experience matters a great deal in large part injection molding. A company with a long - standing presence in the industry has likely encountered and overcome a wide range of challenges. For example, a company that has been in business for over 20 years has had the opportunity to work on diverse projects across multiple industries, such as automotive, aerospace, and consumer goods.

An experienced company also has a team of experts. These professionals understand the nuances of different materials, molds, and injection molding processes. They can provide valuable insights during the design phase to optimize the part for manufacturability. For instance, they can suggest design changes to reduce material waste, improve part strength, or simplify the molding process, which ultimately leads to cost savings and higher - quality products.

2. Equipment and Technology

Advanced injection molding equipment is the backbone of high - quality production. State - of - the - art machines can offer higher injection pressures, more precise temperature control, and faster cycle times. For example, some modern injection molding machines are equipped with servo - hydraulic systems that provide better control over the injection process, resulting in more consistent part quality.

In addition to the machines, technologies like gas - assisted injection molding and multi - shot injection molding can open up new possibilities for product design. Gas - assisted injection molding is useful for creating parts with hollow sections, reducing weight and material usage while maintaining strength. Multi - shot injection molding allows for the combination of different materials in a single part, enabling the creation of complex, high - performance components. A company that invests in such technologies is better equipped to meet the evolving demands of customers.

3. Quality Control Measures

A reliable large part injection molding company has a strict quality control system in place. This starts with the inspection of raw materials. High - quality plastics are essential for producing high - quality parts. The company should conduct regular tests on incoming materials to ensure they meet the required specifications in terms of viscosity, melt flow index, and mechanical properties.

During the production process, in - line quality monitoring is crucial. This can involve using sensors to monitor parameters such as temperature, pressure, and injection speed. Any deviations from the set values can be detected and corrected immediately. After the parts are molded, they undergo thorough final inspections. This may include dimensional checks using coordinate measuring machines (CMMs) to ensure that the parts meet the exact design tolerances, as well as visual inspections to identify any surface defects.

4. Cost - Effectiveness

Cost is an important consideration, but it should not be the sole determining factor. While it's tempting to choose the cheapest option, a company that offers extremely low prices may cut corners on quality or service. Instead, look for a company that offers a good balance between price, quality, and service.

Some companies may offer cost - effective solutions through economies of scale. If they have high - volume production capabilities, they can spread the fixed costs (such as mold production and equipment maintenance) over a larger number of parts, resulting in lower per - unit costs. Additionally, a company that can provide value - added services like design assistance, in - house mold making, and efficient supply chain management can also contribute to overall cost savings. For example, in - house mold making can reduce lead times and eliminate the need to rely on external mold suppliers, which may sometimes lead to communication issues and additional costs.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of large part injection molding in modern manufacturing. We recognize the continuous pursuit of innovation in materials and techniques within this industry.

In terms of materials, we are committed to exploring new material combinations to meet diverse customer needs. For example, we have been researching the application of new types of composite plastics that combine the advantages of multiple materials, aiming to provide products with better performance, such as enhanced strength - to - weight ratios.

Regarding custom - made services, our team of professionals works closely with customers from the initial design stage. We use advanced design software and simulation tools to ensure that the design is optimized for large part injection molding, reducing potential production issues. Our in - house manufacturing capabilities allow us to have better control over the production process, from mold making to the final product, ensuring high - quality and timely delivery. We believe that our focus on material innovation and customized services can bring more value to the large part injection molding industry.

Comparison Table of Leading Large Part Injection Molding Companies

Here is a comparison of several well - known large part injection molding companies to help you make an informed choice.

| Company Name | Company Scale | Areas of Expertise | Product Quality | Price Range | Customer Reviews |

| Company A | Employs over 1000 workers, with a production area of 50,000 square meters and an annual output of large - scale plastic parts reaching 100,000 units. | Specializes in automotive large - part injection molding, such as bumpers, dashboards, and door panels. Also has expertise in industrial equipment parts. | High - quality, with a defect rate of less than 1% according to internal quality control data. Meets ISO 9001 quality management system standards. | Medium - high. The price is relatively competitive considering the quality and the complexity of parts. For example, the price of an automotive bumper is around \(50 - \)100 per piece, depending on the material and design. | Positive reviews from major automotive manufacturers. Customers praise the company's on - time delivery rate of over 95% and its ability to handle complex design requirements. |

| Company B | Has 500 - 800 employees, a production area of 30,000 square meters, and an annual production capacity of 80,000 large - part products. | Focuses on large - part injection molding for the aerospace and marine industries. Produces components like aircraft interior panels and marine equipment housings. | Exceptionally high - quality, meeting strict aerospace and marine industry standards. The rejection rate is controlled within 0.5%. | High - end pricing. Given the high - end materials and strict quality requirements of these industries, the price of a marine equipment housing can range from \(200 - \)500. | Customers in the aerospace and marine sectors commend the company's advanced material research capabilities and its compliance with international standards. |

| Company C | Approximately 300 employees, a production area of 20,000 square meters, and an annual output of 50,000 large - part items. | Specializes in consumer goods large - part injection molding, such as large - scale plastic furniture components and large - sized storage containers. | Good quality, with a quality inspection pass rate of 98%. Meets general consumer product quality standards. | Low - medium. The price of a large - sized plastic storage container is about \(20 - \)50, making it cost - effective for mass - market consumers. | Consumers appreciate the company's diverse product designs and relatively low prices. However, some customers have raised concerns about the long - term durability of certain products. |

FAQ

1. What are the common materials used in large part injection molding?

Common materials include ABS, known for its high strength and good impact resistance, often used in automotive interior components. PP features low density, chemical resistance, and a high melting point, making it suitable for chemical storage tanks and food containers. PE comes in LDPE (flexible, used in plastic films) and HDPE (durable, for pipes). PC offers excellent impact and heat resistance along with good optical properties, utilized in safety shields and headlamp lenses.

2. How can I ensure the quality of large - part injection - molded products?

To ensure quality, start by choosing a company with a robust quality control system. This includes strict inspection of raw materials to verify their quality and compliance with standards. During production, closely monitor parameters like temperature, pressure, and injection speed to detect and correct any deviations promptly. After molding, conduct thorough final inspections, such as dimensional checks using CMMs to ensure parts meet design tolerances and visual inspections for surface defects.

3. What is the approximate cost of large - part injection - molding services?

The cost of large - part injection - molding services varies widely based on several factors. The cost of the mold is a significant upfront expense, with more complex molds being more costly. Material costs depend on the type and quantity of plastic used. Product complexity, such as parts with intricate geometries or tight tolerances, may increase costs due to higher processing requirements. Additionally, the production quantity plays a role; higher volumes often result in lower per - unit costs due to economies of scale. Generally, for simple, small - scale projects, costs might start from a few hundred dollars for the mold and a few dollars per part. For large - scale, complex automotive or aerospace components, costs can range from thousands of dollars for the mold and tens to hundreds of dollars per part.