For startups, engineers, and product developers worldwide, China Rapid Injection Molding has become a pivotal bridge between a 3D-printed prototype and full-scale production. This process expertly balances speed, cost, and part quality, enabling functional testing and small-batch market launches without the high expense of traditional steel molds. However, navigating this landscape as a beginner can be daunting. This guide demystifies China Rapid Injection Molding, explaining the process, its economic advantages, and the critical steps to ensure success. We'll cover everything from understanding rapid tooling materials and lead times to selecting a reliable partner and implementing effective quality control, empowering you to leverage this powerful manufacturing tool with confidence.

What is Rapid Injection Molding?

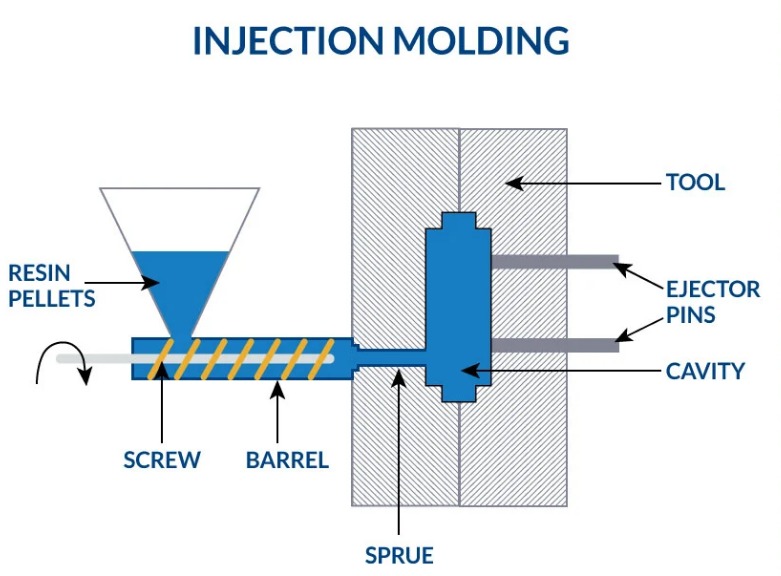

Rapid Injection Molding (RIM) is a manufacturing technique used to produce small to medium quantities (typically 10 to 10,000 parts) of high-quality, injection-molded plastic components in a fraction of the time and cost of conventional molding. The core innovation is rapid tooling—the use of soft metals like aluminum or pre-hardened steel instead of expensive, hardened tool steel. While these molds have a shorter lifespan (often 1,000 to 50,000 shots), they can be manufactured in days or weeks, not months. This makes RIM ideal for prototype validation, bridge tooling for market testing, and low-volume production runs.

Why Choose China for Rapid Injection Molding Services?

China's dominance in this field is built on a powerful ecosystem that offers compelling advantages:

- Cost Efficiency: The primary driver. Lower labor and overhead costs, combined with highly competitive pricing from specialized rapid molding shops, result in significant savings on both tooling and per-part costs. A rapid mold in China can cost 50-70% less than a comparable tool in North America or Europe.

- Consolidated Supply Chain: China hosts dense networks of material suppliers, mold base manufacturers, and post-processing services, all within close proximity. This integration drastically reduces logistics time and cost.

- Speed and Scale: The sheer number of factories creates immense capacity and competition, driving faster lead times. Many shops operate 24/7 to meet aggressive deadlines.

- Technical Experience: Many Chinese manufacturers have over a decade of specialized experience in rapid tooling, refining their processes for speed and reliability.

How Does the Rapid Tooling Process Work?

The process is a streamlined version of traditional molding, focused on speed.

- Design for Manufacturability (DFM) Analysis: The supplier reviews your 3D CAD file, suggesting modifications (draft, wall thickness, etc.) to ensure the part can be molded successfully in the rapid tool.

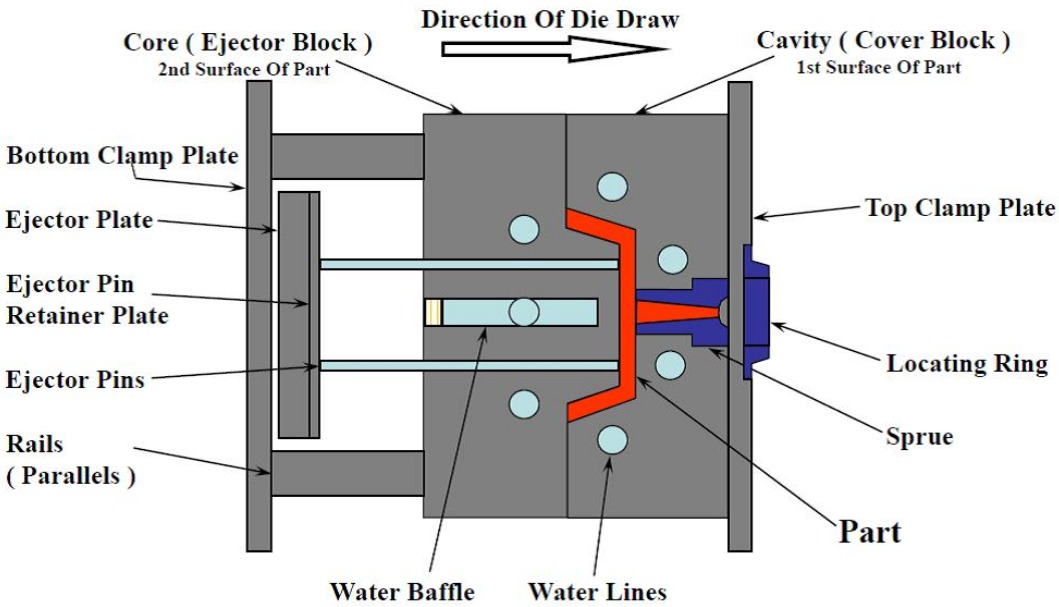

- Mold Design & CNC Machining: A simplified, often single-cavity, mold is designed. The mold cavities and cores are then directly machined from a block of aluminum (e.g., 7075-T6) or a pre-hardened steel using high-speed CNC machines. This is faster than the EDM (Electrical Discharge Machining) processes used for hard steel molds.

- Mold Assembly & Tryout: The machined components are assembled into a standard mold base. The mold is mounted on an injection press for a first-shot trial.

- Sampling & Minor Adjustments: Initial samples are shipped for approval. Minor adjustments to the mold (e.g., polishing, gate size) are often included.

- Production Run: Upon approval, the production of your parts begins.

What are the Typical Lead Times and Costs?

Transparency here is key to setting realistic expectations.

- Lead Time: A complete project from order to shipped parts typically takes 2-5 weeks. This breaks down as:

- Quotation & DFM: 1-3 business days.

- Tooling Fabrication: 10-15 working days.

- Sampling & Production: 5-10 working days.

- Cost Structure:

- Tooling (NRE - Non-Recurring Engineering): $1,500 to $8,000+, depending on part size and complexity. Aluminum molds are at the lower end.

- Per-Part Cost: $1 to $20+, driven by part size, material, and quantity. Economies of scale apply even within "low-volume" runs.

Material Selection for Prototypes vs. Production

Material choice in rapid molding serves different goals than in mass production.

- For Functional Prototypes: Choose materials that mimic the mechanical, thermal, or chemical properties of your final production plastic. Common choices include ABS, PC, Nylon (PA6), and PP. This allows for real-world testing.

- For Low-Volume Production/Bridge Tooling: Select a material that balances performance with processability in an aluminum mold. Some filled or high-temperature materials (e.g., PEEK, glass-filled nylon) can be abrasive or require high temperatures that may reduce aluminum mold life. Your supplier should advise on compatibility.

- Key Point: Almost all standard thermoplastics are available. Always request material certifications for critical applications.

Quality Control Measures in Chinese Factories

Proactive quality management is essential. A reliable partner will have clear QC processes:

- First Article Inspection (FAI): A comprehensive dimensional report on the first shots off the mold, comparing parts to your CAD drawing.

- In-Process Checks: Periodic checks for visual defects (sink, flash), weight, and critical dimensions during the production run.

- Documentation: Providing dimensional reports, material certificates (C of C), and photos of packaged parts before shipping.

- Third-Party Inspection: For critical orders, hiring a local third-party quality inspection firm to perform an on-site check before shipment is a highly recommended and common practice.

How to Select the Right Manufacturing Partner?

Due diligence separates a successful project from a costly mistake.

- Specialization: Look for a supplier whose core business is Rapid Injection Molding, not just a general molder dabbling in it.

- Communication & Transparency: They should respond promptly, provide detailed DFM feedback, and offer a clear, itemized quote. Language barrier should not be an issue with a competent partner.

- Request Evidence: Ask for case studies, photos/videos of their facility, and samples of previous rapid molding work similar to your project.

- Ask Specific Questions: “What is your standard mold material for a part of X size?” “How do you handle design changes after the mold is made?” “Can you provide a sample FAI report?”

- Start Small: Consider a small, non-critical first project to evaluate their performance, communication, and quality before committing to a major order.

Conclusion

China Rapid Injection Molding is an extraordinarily powerful tool for accelerating product development and mitigating financial risk. By understanding its principles—the use of cost-effective rapid tooling, condensed timelines, and a focus on functional low-volume parts—you can leverage it effectively. Success hinges on clear communication, informed material selection, realistic expectations of cost and lead time, and, most importantly, partnering with a specialized and transparent supplier. For beginners, taking a methodical, informed approach to China Rapid Injection Molding opens the door to bringing higher-fidelity products to market faster and more affordably than ever before.

FAQ on China Rapid Injection Molding

What is the main disadvantage of rapid injection molding?

The primary trade-off is mold life and part cost at high volumes. Aluminum tools wear out faster than hardened steel. While per-part cost is low for batches of 1,000, it becomes uneconomical compared to a steel mold for runs of 100,000+ parts. It's a solution for the "bridge" phase, not mass production.

Can rapid injection molds be used for production materials like glass-filled nylon?

Yes, but with caution. Abrasive filled materials (glass, minerals) will significantly reduce the lifespan of an aluminum mold. For such materials, discuss using a pre-hardened steel insert for the cavity/core, which is a common compromise in rapid tooling to balance cost and durability.

How accurate are the parts from a rapid mold compared to a production mold?

With a well-machined mold and proper process control, parts from a rapid mold can achieve near-production quality and tolerances (±0.1mm or better is common). The difference often lies in cosmetic surface finish or the potential for more wear-related variation over the life of the tool.

Who owns the mold (tooling) after the project?

This must be explicitly negotiated. Typically, the client pays for and owns the mold. The supplier stores it for a period (e.g., 1-2 years), often for a small fee. Ensure the quote specifies tooling ownership and storage terms.

What file format should I provide for a quote?

A 3D CAD file in STEP or IGES format is industry standard. Always include a 2D PDF drawing with critical dimensions, tolerances, and material specifications. The more information you provide upfront, the more accurate the quote and DFM will be.

Contact Yigu technology for custom manufacturing.

At Yigu Technology, we specialize in guiding beginners and experts alike through the China Rapid Injection Molding process. We combine transparent communication, expert DFM analysis, and a streamlined workflow to deliver high-quality prototypes and low-volume production parts on time and on budget. Our focus on rapid tooling with aluminum and pre-hardened steel ensures you get the speed and cost benefits without compromising on part functionality.

Let us be your trusted partner to bridge the gap from design to market-ready product.

Contact Yigu Technology today for a fast, detailed quote and expert DFM review of your project.