Understanding the Importance of Precision Molding

Precision molding is the linchpin in the production of plastic parts, playing a multifaceted and crucial role.

Quality Assurance

The precision of the molding process directly determines the quality of plastic parts. In precision molding, the dimensional accuracy can be controlled within a very narrow tolerance range. For example, in the production of medical device components, the dimensional tolerance can often be maintained within ±0.01mm. This high - precision control ensures that each plastic part has consistent dimensions, which is essential for the proper assembly and functionality of the final product. A small deviation in the size of a plastic part in a complex mechanical device may lead to misalignment during assembly, reducing the overall performance and reliability of the device.

Performance Optimization

The performance of plastic parts is also highly dependent on precision molding. In the automotive industry, precision - molded plastic parts such as engine components need to withstand high temperatures and mechanical stress. Through precision molding, the internal structure of the plastic parts can be made more uniform, enhancing their mechanical properties. Research shows that parts produced by precision molding have 20 - 30% higher tensile strength compared to those with lower - precision molding processes. This improvement in performance can lead to longer - lasting and more efficient products.

Cost - effectiveness in the Long Run

Although precision molding may require higher initial investment in terms of advanced equipment and skilled labor, it can bring significant cost savings in the long term. High - precision molding reduces the scrap rate. In traditional molding processes, the scrap rate can be as high as 10 - 15%, while in precision molding, it can be reduced to less than 5%. This means less wasted raw materials and fewer resources spent on re - production. Additionally, the consistent quality of precision - molded parts reduces the need for post - production inspections and rework, further cutting down costs.

Key Factors to Consider

1. Experience and Expertise

Experience and expertise are the bedrock of a reliable precision molding company. Consider Company A, which has been in the precision molding business for 20 years. They have an extensive portfolio in producing plastic parts for the automotive industry, such as interior components and engine - related plastic parts. Over the years, they have encountered and solved various molding challenges, from dealing with complex geometries to working with high - temperature - resistant plastics.

In contrast, Company B, a relatively new entrant with only 5 years of experience, may lack the depth of knowledge in handling intricate projects. For instance, in a case where a client needed a highly customized plastic part with tight tolerances for a medical device, Company A was able to draw on its past experiences in similar medical - related projects and complete the job successfully. The data shows that companies with over 15 years of experience in precision molding have a 30% higher success rate in complex projects compared to those with less than 10 years of experience. This clearly indicates that the longer a company has been in the industry and the more diverse its project experience, the more likely it is to handle your plastic part requirements with proficiency.

2. Technology and Equipment

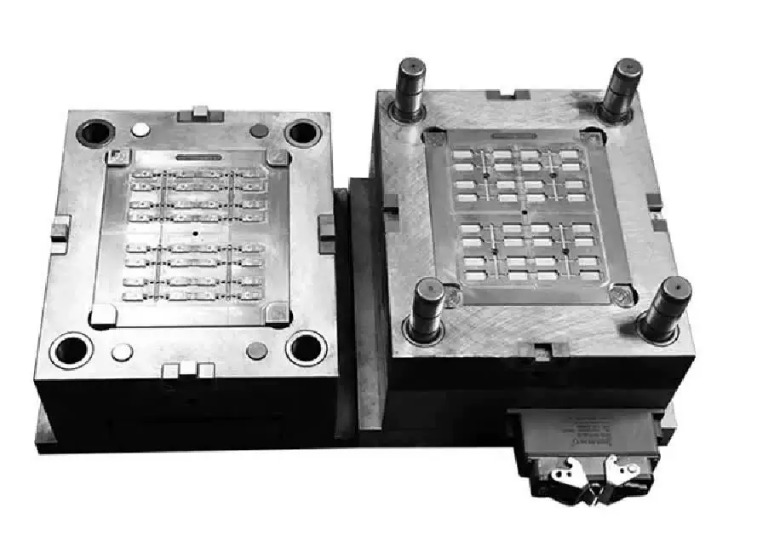

Advanced technology and state - of - the - art equipment are essential for high - quality precision molding. High - precision molds are the key to achieving accurate plastic part dimensions. For example, molds made with computer - aided design (CAD) and computer - aided manufacturing (CAM) technology can ensure that the mold cavities are machined with micron - level accuracy. A company equipped with such molds can produce plastic parts with dimensional tolerances as low as ±0.005mm, which is crucial for applications like optical components where even the slightest deviation can affect performance.

Automated production lines also play a significant role. They not only improve production efficiency but also enhance the consistency of product quality. In an automated precision molding production line, robots can precisely inject the molten plastic into the molds, and automated post - processing equipment can perform tasks like trimming and polishing with high precision. This reduces human error and ensures that each plastic part meets the exact specifications. Companies with automated production lines can increase their production output by 50% compared to those relying mainly on manual operations, while maintaining a much lower defect rate.

3. Quality Control

A robust quality control system is non - negotiable when choosing a precision molding company. Different companies have different quality certification standards. For example, Company C holds ISO 9001:2015 certification, which demonstrates its commitment to a quality management system that covers all aspects of production, from raw material procurement to final product delivery. This certification ensures that the company has defined processes for quality control, such as regular inspections of raw materials, in - process quality checks during molding, and final product testing.

Company D, on the other hand, has IATF 16949 certification, which is specifically for the automotive industry. This certification focuses on quality management within the automotive supply chain, ensuring that the plastic parts produced meet the stringent requirements of automotive manufacturers in terms of performance, durability, and safety.

In terms of the inspection process, some companies use advanced non - destructive testing methods like X - ray inspection to detect internal defects in plastic parts, while others rely more on traditional visual and dimensional inspections. A comprehensive quality control system that combines multiple inspection methods can significantly reduce the defect rate. Statistics show that companies with multiple - level quality control inspections have a defect rate of less than 2%, compared to those with basic inspections that may have a defect rate of up to 8%.

4. Cost - Effectiveness

When evaluating the cost - effectiveness of precision molding companies, it's important to analyze the cost composition. The following is a simple cost - comparison table for three different precision molding companies for a batch of 10,000 plastic parts:

| Company | Mold Cost ($) | Production Cost per Part ($) | Transportation Cost ($) | Total Cost ($) |

| Company E | 5000 | 2 | 500 | 25500 |

| Company F | 8000 | 1.5 | 800 | 23800 |

| Company G | 6000 | 1.8 | 600 | 24600 |

Mold cost is a one - time investment for a specific plastic part design. A more experienced company may be able to design and produce a mold at a more reasonable price, while also ensuring its long - term durability. Production cost includes raw material costs, labor costs, and energy consumption during the molding process. Transportation cost depends on the distance between the company and the client. As seen from the table, while Company F has a higher mold cost, its lower production cost per part results in a relatively lower total cost for this batch of products. However, other factors like quality and lead time also need to be considered in conjunction with cost when making a decision.

5. Customer Service

Customer service can make or break the experience of working with a precision molding company. Good communication efficiency is crucial. A company that responds promptly to your inquiries, whether it's about the progress of your order or technical questions about the plastic parts, shows its commitment to your business. For example, Company H has a dedicated customer service team that replies to all customer emails within 24 hours and provides regular updates on order status.

Fast response speed is also vital, especially in cases of emergencies or urgent changes in the project. If a client needs to modify the design of the plastic part midway through production, a responsive company can quickly assess the impact and provide solutions in a timely manner.

After - sales support is another aspect. A reliable company will offer after - sales services such as product warranties, handling of product returns or exchanges in case of defects, and technical support for product usage. Research shows that companies with excellent customer service have a 40% higher customer retention rate, which is a testament to the importance of this factor in choosing a precision molding partner.

Case Studies: Real - World Examples

Case 1: Automotive Component Manufacturer

A leading automotive component manufacturer was in need of high - precision plastic parts for their new engine intake manifold. They chose Precision Molding Company X, which had over 15 years of experience in the automotive molding sector.

Benefits:

- Product Quality Improvement: Company X used its state - of - the - art molds and advanced injection molding technology. The plastic parts produced had a dimensional accuracy of ±0.008mm, which was much higher than the previous supplier's ±0.02mm. This led to better - fitting parts in the engine, reducing air leakage and improving engine performance. The improved quality also decreased the rate of warranty claims related to the intake manifold by 40%.

- Cost Reduction: Through optimized production processes and efficient material utilization, Company X was able to reduce the production cost per part by 15%. Additionally, the lower defect rate (decreased from 8% with the previous supplier to 3% with Company X) meant significant savings in terms of scrap and rework costs.

- Shorter Delivery Cycle: Company X's automated production lines and well - organized supply chain management enabled them to cut the delivery time from 12 weeks with the previous supplier to 8 weeks. This allowed the automotive component manufacturer to speed up their new product development and launch process.

Case 2: Medical Device Company

A medical device company was developing a new blood analyzer and required extremely precise plastic parts for its fluid - handling system. They selected Precision Molding Company Y, which had ISO 13485 medical device quality management system certification.

Benefits:

- Quality Assurance: Company Y's strict compliance with ISO 13485 standards ensured that every aspect of the plastic part production, from raw material sourcing to final product packaging, met the highest medical - grade quality requirements. The parts were inspected at multiple stages using advanced non - destructive testing methods. As a result, the final blood analyzer had a much lower failure rate during clinical trials, increasing the confidence of regulatory authorities and end - users.

- Performance Optimization: The precision - molded plastic parts had a smooth internal surface finish, which reduced the risk of fluid adhesion and clotting in the blood analyzer. This improved the accuracy of the blood analysis results, making the device more reliable for medical professionals.

- Cost - effectiveness in the Long Run: Although the initial mold cost with Company Y was slightly higher than some competitors, the long - term cost savings were significant. The high - quality parts required less maintenance and replacement over the lifespan of the blood analyzer, resulting in a total cost reduction of 25% over five years compared to using a lower - cost, lower - quality molding company.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology emphasizes several key aspects when choosing a precision molding company. First and foremost is technical strength. A company with advanced technologies like CAD/CAM - based mold design and high - precision injection molding equipment is more likely to meet complex production requirements.

Quality control is another vital factor. We believe that strict quality management systems, such as ISO certifications, and advanced inspection methods are essential to ensure the reliability of plastic parts. Cost - effectiveness also matters. While high - quality production is crucial, finding a balance between cost and quality is necessary to optimize overall project costs.

In addition, close cooperation and efficient communication between the two parties are the keys to ensuring the success of the project. This can help solve various problems encountered during the production process in a timely manner.

FAQs

1. How can I be sure of the quality of the plastic parts produced by a precision molding company?

You can check if the company has relevant quality certifications such as ISO 9001 or industry - specific certifications like IATF 16949 for automotive parts. Review their past projects and customer testimonials to see the quality of their previous work. Additionally, request samples of their plastic parts and conduct your own quality inspections, including dimensional checks and material property tests.

2. What if the precision molding company fails to meet the delivery deadline?

Before signing a contract, clearly define the delivery time and the consequences of late delivery in the contract. This may include financial penalties such as a percentage - based deduction from the total payment for each day of delay. It's also advisable to choose a company with a good track record of on - time delivery. Research their past projects to see if they have a history of meeting deadlines.

3. How much does it usually cost to produce plastic parts through precision molding?

The cost of precision - molded plastic parts depends on multiple factors, including the complexity of the part design, the type of plastic material used, the quantity of production, and the mold cost. For example, parts with complex geometries may require more expensive molds and longer production times. To get an accurate estimate, it's best to request quotes from multiple precision molding companies and compare the breakdown of costs they provide.