Introduction

Fluoropolymers are highly regarded for their exceptional performance in extreme environments, but injection molding these materials comes with unique challenges. Manufacturers often struggle with their high processing temperatures, which demand specialized equipment. The low friction and non-stick properties that make fluoropolymers valuable also cause issues with mold filling and part ejection. Additionally, ensuring consistent chemical resistance and avoiding defects in high-performance applications can be tricky. This guide explores every aspect of fluoropolymer injection molding to help overcome these hurdles.

1. Material Properties of Fluoropolymers

Fluoropolymers include well-known types like Polytetrafluoroethylene (PTFE), Perfluoroalkoxy (PFA), and Fluorinated ethylene propylene (FEP). Their standout feature is chemical resistance—they resist nearly all acids, bases, and solvents, even at high temperatures. For example, PFA can withstand exposure to concentrated sulfuric acid at 200°C without degradation.

Thermal stability is another key property. PTFE remains stable up to 260°C, while PFA and FEP can handle 260°C and 200°C respectively, making them ideal for high-temperature applications. They also offer excellent electrical insulation, with volume resistivity exceeding 10¹⁸ Ω·cm, crucial for electrical components.

The low friction coefficient of fluoropolymers (as low as 0.04 for PTFE) gives them superior non-stick capabilities. However, this also means lower mechanical strength compared to some plastics, with tensile strength ranging from 15-30 MPa. They exhibit good UV resistance and weatherability, maintaining properties even after years of outdoor exposure.

2. Injection Molding Process for Fluoropolymers

2.1 Critical Process Parameters

- Melt Temperature: Fluoropolymers require high melt temperatures. PFA processes at 350-400°C, FEP at 300-350°C, and modified PTFE grades at 380-420°C. Precise temperature control (±2°C) is vital to avoid degradation.

- Injection Speed and Pressure: Due to their high viscosity, injection speeds are moderate (10-30 mm/s). Injection pressure ranges from 800-1500 bar, with PFA often needing the higher end to fill complex molds.

- Cooling Time and Cycle Time: Cooling time is relatively long (20-40 seconds) due to low thermal conductivity. Total cycle times typically range from 60-120 seconds, significantly longer than for traditional plastics.

2.2 Material Handling and Preparation

Drying requirements vary by type. PFA and FEP should be dried at 120-150°C for 4-6 hours to remove moisture, while PTFE-based grades are often pre-dried by suppliers. Material handling requires care—avoid contact with oils or contaminants that can compromise chemical resistance.

High-temperature processing demands specialized equipment with nickel-plated barrels and screws to resist corrosion from fluoropolymer degradation byproducts.

3. Mold Design for Fluoropolymers

3.1 Key Design Features

- Venting Requirements: Fluoropolymers release volatile byproducts during melting, so vents must be larger (0.03-0.05 mm deep and 10-15 mm wide) than for other plastics. Position vents at flow path ends and around thick sections.

- Cooling Channel Layout: To handle high temperatures, cooling channels should be 6-10 mm from the cavity surface with a diameter of 8-12 mm. Use turbulent water flow (3-5 m/s) for efficient heat removal.

- Draft Angles and Surface Finish: Due to non-stick properties, draft angles must be larger (3-5° per side) than for other materials. A smooth surface finish (Ra 0.4-0.8 μm) helps, but some molds use special coatings to improve release.

3.2 Mold Materials and Systems

Molds for fluoropolymers require heat-resistant materials. H13 tool steel is standard, while nickel-based superalloys are used for extremely high-temperature grades. Hot runner systems must be made of corrosion-resistant alloys (like Hastelloy) and operated at 320-400°C for PFA.

4. Quality Control and Defects in Fluoropolymers Molding

4.1 Common Defects and Solutions

| Defect | Cause | Solution |

| Warpage | Uneven cooling or mold temperature gradients | Balance cooling channels; use mold temperature controllers with ±1°C accuracy |

| Voids | Trapped air or moisture degradation | Increase venting; improve drying process |

| Short Shots | Insufficient melt temperature or pressure | Raise temperature by 5-10°C; increase injection pressure |

| Surface Defects | Mold contamination or degradation | Clean mold with fluorinated solvents; reduce melt temperature |

4.2 Quality Control Measures

Implement statistical process control to monitor melt temperature, pressure, and cycle time, with variations kept within ±1%. Test chemical resistance of sample parts using aggressive fluids like nitric acid. Check dimensional accuracy with CMMs, maintaining tolerances of ±0.05 mm for critical components.

For non-stick surface defects, perform contact angle measurements—values below 100° indicate surface issues that compromise performance.

5. Applications of Fluoropolymers in Injection Molding

5.1 Key Application Areas

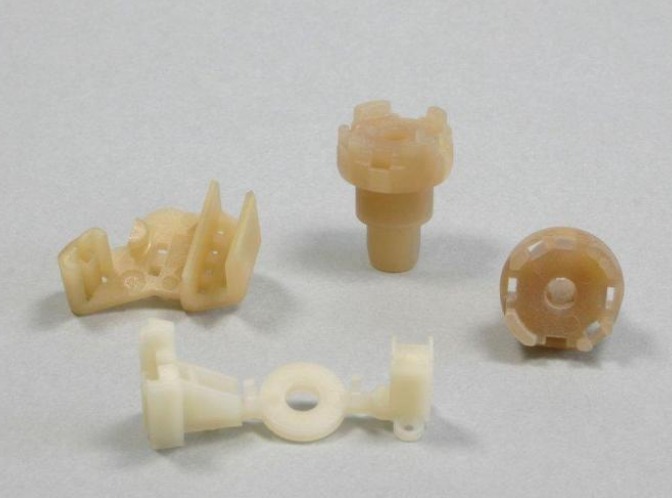

- Chemical Processing Equipment: Valves, seals, and pump components made from PFA and FEP resist corrosive fluids, ensuring long service life in chemical plants.

- Electrical Components: FEP and PFA insulators and connectors maintain electrical properties in high-temperature environments like engine bays.

- Medical Devices: PTFE and PFA parts are used in surgical instruments and fluid handling systems due to chemical inertness and biocompatibility.

- Aerospace Components: Fluoropolymer parts withstand extreme temperatures and fuels in aircraft hydraulic systems and engine components.

6. Post-Processing and Finishing of Fluoropolymers Parts

6.1 Effective Techniques

- Machining and Trimming: Use carbide tools with high cutting speeds (1500-3000 RPM) to avoid heat buildup. Coolant should be alcohol-based to prevent residue.

- Adhesive Bonding: Special surface treatments (like plasma etching) are needed to improve adhesion. Use fluoropolymer-specific adhesives cured at 120-150°C.

- Heat Treatment: Annealing at 150-200°C for 1-2 hours relieves internal stresses, reducing warpage in critical parts.

Yigu Technology, a custom manufacturing supplier in China, has extensive experience in fluoropolymer injection molding. We use specialized high-temperature equipment and precision molds to produce PFA, FEP, and modified PTFE parts. Our focus on strict process control ensures parts meet the demanding performance requirements of chemical, aerospace, and medical industries, making us a reliable partner for high-performance fluoropolymer components.

FAQs

- Can fluoropolymers be recycled?

Yes, but recycling is limited. Scrap fluoropolymers can be ground and reused in lower-performance applications, but the high processing temperatures make recycling energy-intensive.

- What causes fluoropolymer parts to have reduced chemical resistance?

Overheating during processing (above 420°C for PFA) can break chemical bonds, reducing resistance. Contamination with other plastics or oils during handling also compromises this property.

- How to improve mold filling for complex fluoropolymer parts?

Increase melt temperature by 10-15°C, use larger gates (1-2 mm diameter), and ensure adequate venting. Sequential valve gating can help fill intricate sections without trapping air.