Introduction

Definition and Basics of Co - Injection Molding

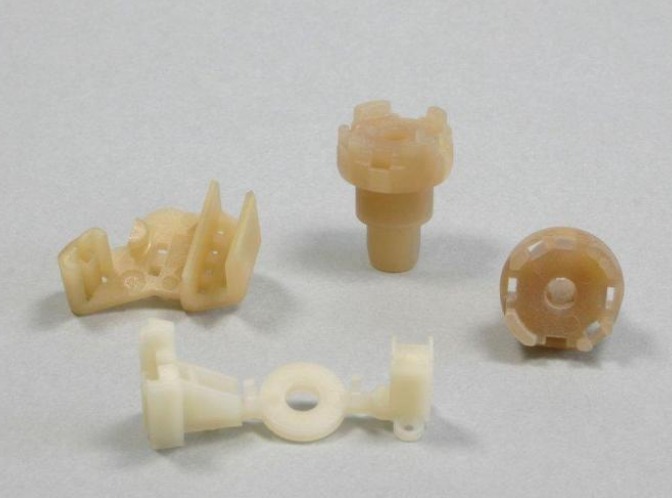

Co - Injection Molding, also known as sandwich injection molding or co - injection, is a specialized form of multi - material injection molding. In this process, two or more different materials are injected into a mold cavity in a sequential or simultaneous manner to create a single, integrated part. This results in a component with a distinct layered structure, typically consisting of a core layer surrounded by one or more outer layers, or skins.

Importance and Popularity in the Manufacturing Industry

Co - Injection Molding has gained significant importance and popularity in the manufacturing industry due to its ability to offer numerous advantages over traditional single - material injection molding processes. Here are some reasons highlighting its significance:

- Enhanced Product Performance: By combining different materials, co - injection molding allows manufacturers to create products with improved mechanical properties, such as increased strength, stiffness, and impact resistance. For example, in the automotive industry, co - injection molded parts like bumpers can have a soft outer layer for better shock absorption and a rigid inner core for structural integrity.

- Cost - Efficiency: Using a combination of materials, especially when incorporating less expensive or recycled materials in the core, can reduce material costs without sacrificing overall product quality. This is particularly beneficial for high - volume production runs.

- Design Flexibility: The process enables the creation of complex shapes and geometries that may not be achievable with single - material injection molding. It also allows for the integration of multiple functions into a single part, reducing the need for additional assembly operations.

- Aesthetic Appeal: Co - injection molding can produce parts with a smooth, high - quality surface finish, as well as the ability to combine different colors or textures in a single component. This is highly desirable in consumer products, such as electronics and household appliances.

The applications of co - injection molding span across various industries:

| Industry | Examples of Applications |

| Automotive | Interior components (dashboard, door panels), exterior parts (bumpers, fenders), engine components |

| 3C Electronics | Mobile phone cases, laptop housings, camera bodies |

| Medical | Syringe barrels, medical device housings, prosthetics components |

| Consumer Goods | Toys, kitchenware, bathroom fixtures |

| Packaging | Cosmetic containers, food packaging, beverage bottles |

These applications demonstrate the versatility and wide - ranging utility of co - injection molding in modern manufacturing processes.

The Process of Co - Injection Molding

Step - by - Step Explanation

- Initial Skin Material Injection:

- First, the injection molding machine injects the outer skin material into the mold cavity. This material will form the outer layer of the final product, which is crucial for aspects like surface appearance and initial protection. For example, in the production of a mobile phone case, the skin material might be a high - gloss plastic that gives the case an attractive finish. The injection pressure and speed are carefully controlled at this stage. Typically, the injection pressure for the skin material can range from 50 - 100 MPa, depending on the type of plastic and the complexity of the mold.

- Core Material Injection:

- Once the skin material has partially filled the mold cavity, the core material is injected. The core material provides the structural strength and bulk of the part. In the case of a plastic chair, the core material could be a cheaper, more rigid plastic that gives the chair its stability. The injection of the core material needs to be timed precisely so that it does not disrupt the already - injected skin material. The injection speed of the core material is often set to be slightly slower than that of the skin material, usually around 30 - 60 mm/s.

- Final Skin Material Encapsulation:

- After the core material is injected, a second shot of the skin material is used to completely encapsulate the core. This ensures that the core is fully covered and the final product has a smooth, consistent outer surface. This final injection also helps in improving the overall integrity of the part. For instance, in the manufacturing of a car bumper, the final skin material injection strengthens the bond between the core and the outer layer, enhancing the bumper's durability.

Equipment and Tools Involved

- Injection Molding Machine:

- A specialized injection molding machine with at least two injection units is required for co - injection molding. Each injection unit is responsible for injecting a different material. These machines can range in size and capacity. Small - scale machines might have a clamping force of around 50 - 100 tons and are suitable for producing small - sized parts like electronic components. Larger industrial - scale machines can have a clamping force of 1000 tons or more, used for manufacturing large automotive parts. The injection units are equipped with precise metering systems to control the amount of material injected accurately.

- Molds:

- The molds used in co - injection molding are designed with complex flow channels and cavities. They need to accommodate the sequential injection of different materials. For example, the mold might have a primary cavity for the initial skin material injection, a secondary path for the core material injection, and then a way to allow the final skin material to flow and encapsulate the core. The mold surfaces are often highly polished to ensure a smooth finish on the product's outer layer. Additionally, molds may be made of high - quality steel, such as P20 or 718 steel, which can withstand the high pressures and temperatures during the injection process. These steels have good machinability and wear - resistance properties, ensuring a long lifespan for the molds.

Real - World Applications

Case Studies in Different Industries

Automotive Industry

In the automotive industry, co - injection molding has been widely adopted to improve the performance of various components while reducing costs. For example, in the production of car bumpers, co - injection molding allows for the combination of a soft, impact - absorbing outer layer and a rigid, high - strength inner core. The outer layer, often made of a thermoplastic elastomer (TPE), can effectively absorb the impact energy during a collision, reducing damage to the vehicle body. The inner core, typically composed of a more rigid plastic like polypropylene (PP), provides the necessary structural support.

This not only enhances the safety performance of the bumper but also reduces material costs. A study by a leading automotive parts manufacturer found that by using co - injection molding for bumpers, the material cost per bumper was reduced by about 15% compared to traditional single - material injection molding, while the impact resistance was increased by 20%.

Another application is in interior components such as dashboard panels. Co - injection molding enables the creation of a soft - touch outer surface for a more comfortable and luxurious feel, combined with a strong inner structure for stability. The soft outer layer can be made of a material with good tactile properties, and the inner layer of a high - strength plastic to withstand the mechanical stresses during vehicle operation.

Consumer Electronics

In the 3C (computer, communication, consumer electronics) products sector, co - injection molding plays a crucial role in product design and functionality enhancement. Take mobile phone cases as an example. Co - injection molding allows for the integration of multiple functions into a single case. A hard, impact - resistant inner layer can protect the phone's internal components from drops and impacts, while a soft, anti - slip outer layer provides a better grip for users.

Moreover, co - injection molding can create a more aesthetically pleasing appearance. Different colors or textures can be combined in the same case, giving consumers more choices. In the production of high - end smartphones, some manufacturers use co - injection molding to create a metal - like finish on the outer layer of the case, enhancing the product's overall appeal.

For earphones, co - injection molding can be used to produce a more comfortable and durable earbud housing. The inner part can be made of a rigid material for structural integrity, and the outer part that comes in contact with the ear can be made of a soft, skin - friendly material, improving user experience.

Medical Devices

In the medical device manufacturing industry, co - injection molding is essential for meeting strict hygiene and performance requirements. For instance, in the production of syringe barrels, co - injection molding can be used to create a smooth, non - toxic outer surface and a strong, lightweight inner structure. The outer layer, usually made of a medical - grade plastic with excellent biocompatibility, ensures that there is no risk of chemical leaching into the medical fluid. The inner layer can be designed to have high mechanical strength to withstand the pressure during the injection process.

Medical device housings also benefit from co - injection molding. A study showed that for medical device housings produced by co - injection molding, the resistance to sterilization processes (such as autoclaving) was improved by 30% compared to traditional single - material housings. This is because the combination of materials can better withstand the high - temperature and high - pressure conditions during sterilization. Additionally, co - injection molding can be used to create antimicrobial surfaces in some medical devices, by incorporating antimicrobial agents into the outer layer material, which is crucial for preventing the growth of harmful bacteria and ensuring patient safety.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the potential of Co - Injection Molding. We recognize that this technology offers vast opportunities for product innovation. By combining different materials, we can create unique products that meet the diverse and evolving needs of our clients.

In terms of cost control, co - injection molding allows us to use a combination of materials, with more cost - effective options for the core and higher - performance materials for the outer layers. This approach not only reduces material costs but also ensures high - quality end - products.

With our rich experience and advanced technical capabilities in the field of plastic and metal product customization, we are well - equipped to handle complex co - injection molding projects. Our team of experts can work closely with clients to develop customized solutions, from the initial design concept to the final production. We are committed to leveraging co - injection molding technology to deliver products that are not only functional but also cost - efficient and aesthetically pleasing, helping our clients gain a competitive edge in the market.

FAQ

What is the difference between co - injection molding and traditional injection molding?

The main difference lies in the materials used and the resulting product structure. In traditional injection molding, a single material is injected into the mold cavity to form the product. This is suitable for products that do not require complex material combinations. For example, many simple plastic toys are made by traditional injection molding with a single type of plastic.

On the other hand, co - injection molding uses two or more different materials. It can create products with a layered structure, such as a soft outer layer and a rigid inner core. This allows for the combination of different material properties, making co - injection molding suitable for products that need enhanced performance, like automotive bumpers or high - end consumer electronics cases.

What types of products are most suitable for co - injection molding?

Products that require multiple material properties are highly suitable for co - injection molding. For instance, products that need both high strength and good aesthetic appearance, such as laptop housings which require a rigid inner structure for protecting components and an attractive outer surface.

Products with complex functions are also good candidates. In the automotive industry, components like door panels need to have sound - insulation properties, impact resistance, and a good - looking interior surface, all of which can be achieved through co - injection molding. Products that require a combination of different materials, such as a product with a conductive inner layer for electrical functions and a non - conductive outer layer for safety, are also well - suited for this process.