What is Dual Shot Injection Molding?

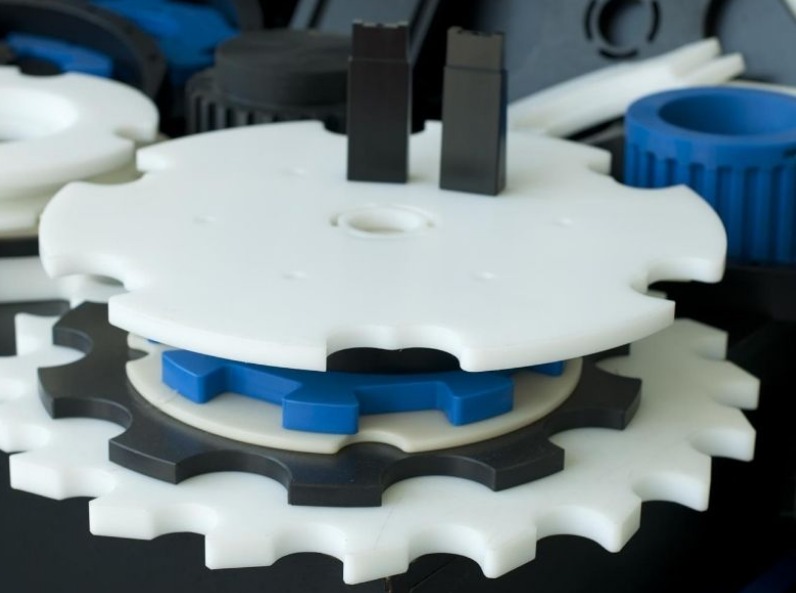

Dual Shot Injection Molding, also known as two - shot or multi - shot injection molding, is an advanced manufacturing process. It involves injecting two different materials, one after the other, into the same mold to create a single, integrated part. This process allows for the combination of materials with distinct properties, such as different colors, hardness levels, or chemical resistances, all within a single component.

For example, in the production of a toothbrush, the handle might be made of a rigid plastic like polypropylene (PP) for strength and easy gripping, while the bristles are made of a flexible nylon material. Dual Shot Injection Molding enables these two different materials to be molded together in one seamless operation, eliminating the need for additional assembly steps.

Another common application is in the automotive industry. Car interior components like dashboard knobs often require a soft - touch surface for a comfortable grip and a hard plastic core for structural integrity. Dual shot molding can achieve this by first injecting the hard plastic and then over - molding it with the soft material. This not only improves the functionality of the part but also enhances its aesthetic appeal.

How Does Dual Shot Injection Molding Work?

?

Machine Setup

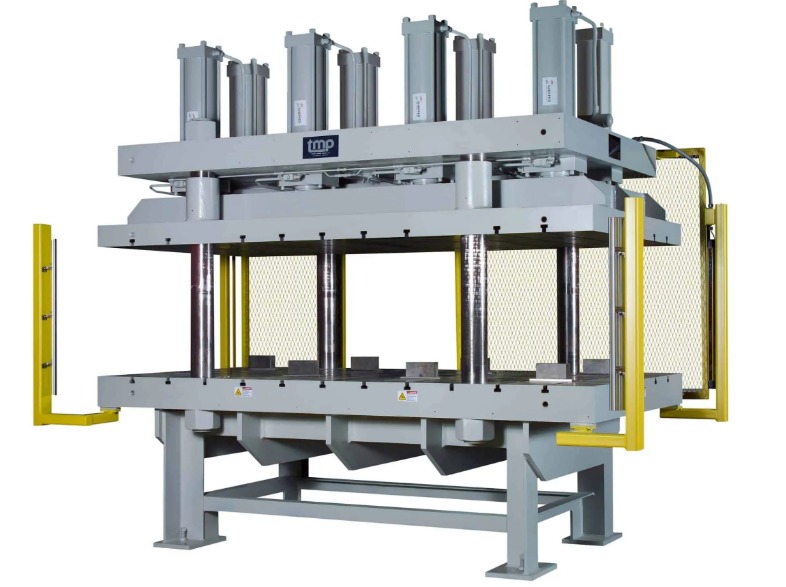

Dual shot injection molding requires a specialized injection molding machine. This machine is equipped with two injection units, each capable of handling a different type of plastic material. These injection units are carefully calibrated to ensure precise control over the injection process of each material.

The mold used in dual shot injection molding also has a unique design. It often features a rotating or moving mechanism. For example, in a rotary - type mold, after the first injection, the mold can rotate 180 degrees, presenting a different cavity or the same cavity in a new position for the second injection. This precise mold movement is crucial for the success of the dual shot process.

First Injection

The first step in the dual shot injection molding process is the first injection. First, the chosen plastic material for the base layer is fed into the first injection unit. Inside the injection unit, the plastic pellets are heated to a specific temperature. For instance, if the material is polypropylene (PP), it is typically heated to around 180 - 230°C. As the temperature rises, the plastic pellets melt and transform into a viscous, flowing state.

Once fully melted, the molten plastic is then forcefully injected into the mold cavity. The injection pressure can vary depending on the complexity of the mold and the properties of the plastic, but it usually ranges from 50 - 200 MPa. After injection, the plastic - filled mold is allowed to cool. This cooling process can be facilitated by circulating cool water or other cooling media through channels in the mold. As the plastic cools, it solidifies, taking on the shape of the mold cavity. This solidified plastic forms the base structure or the first part of the final product.

Second Injection

After the first injection has cooled and solidified, the mold is re - positioned. If it's a rotary - type mold, it rotates; if it's a slide - type mold, it moves to the appropriate position for the second injection. The second plastic material, which may have different properties such as color, hardness, or flexibility, is then introduced into the second injection unit.

This second material is also heated to its melting point. For example, if the second material is a thermoplastic elastomer (TPE) being used to create a soft - touch surface on a product with a hard plastic core, it is heated to its specific melting range, usually around 100 - 150°C. Once melted, the second material is precisely injected into the mold. The key here is to ensure that the second - injected material bonds well with the first - injected material. This is often achieved by carefully designing the mold and controlling the injection parameters such as temperature, pressure, and injection speed. The second - injected material adheres to the first - injected part, creating a single, integrated component with two distinct materials.

Applications of Dual Shot Injection Molding

Dual shot injection molding has found extensive applications across various industries due to its ability to combine different materials and enhance product functionality.

Automotive Industry

In the automotive industry, dual shot injection molding is widely used for both interior and exterior components. For interior parts, it is commonly employed in the production of dashboards. The dashboard often requires a combination of a rigid structural material for support and a soft, tactile material on the surface for a comfortable feel and to reduce glare. By using dual shot injection molding, manufacturers can first inject a strong plastic like acrylonitrile - butadiene - styrene (ABS) as the core structure, and then over - mold it with a soft thermoplastic elastomer (TPE). This results in a dashboard that is not only durable but also provides a more pleasant user experience.

Door handles are another example. The inner part of the door handle, which needs to withstand mechanical stress during operation, can be made of a high - strength plastic such as polypropylene (PP). The outer part, which comes into contact with the user's hand, can be molded with a soft - touch material using dual shot injection molding. This soft outer layer improves grip, especially in wet or cold conditions, and also adds an aesthetic appeal to the vehicle interior.

For exterior components, dual shot injection molding can be used to create parts like side mirror housings. A hard, weather - resistant plastic can be used for the main body of the housing to protect the internal mechanisms from environmental factors such as rain, UV rays, and temperature changes. A second, more flexible and impact - resistant material can be over - molded around the edges or in specific areas to enhance the housing's durability in case of minor collisions or impacts.

Consumer Electronics

In the consumer electronics industry, dual shot injection molding plays a crucial role in enhancing both the functionality and aesthetics of products. For example, in the production of smartphone cases, dual shot injection molding allows for the combination of a hard outer shell for protection against drops and scratches and a soft inner layer that cushions the phone and provides a better grip. This combination of materials not only improves the overall protection of the device but also makes it more comfortable to hold.

Many electronic devices also use dual shot injection molding for button manufacturing. Buttons often require a hard base for stability and a soft, tactile surface for easy pressing. By using dual shot injection molding, manufacturers can create buttons that are responsive, durable, and provide a pleasant user experience. Additionally, the ability to use different colors for the two materials allows for greater design flexibility, enabling the creation of visually appealing and distinguishable buttons.

Medical Devices

The medical device industry has strict requirements for material safety and hygiene, and dual shot injection molding can meet these needs. In the manufacturing of medical device components, such as syringe plungers, dual shot injection molding can be used to combine a rigid plastic for structural integrity and a soft, biocompatible material at the tip. The soft material at the tip ensures a better seal within the syringe barrel, preventing leakage, while also being gentle on the inner walls of the barrel.

Some medical device housings also benefit from dual shot injection molding. A hard, impact - resistant plastic can form the main body of the housing to protect the internal components. A second, antimicrobial - treated material can be over - molded on the surface that comes into contact with medical staff or patients. This antimicrobial layer helps prevent the growth and spread of harmful bacteria and viruses, ensuring a higher level of hygiene in medical environments.

Comparison with Other Molding Methods

When considering manufacturing processes, it's important to understand how dual shot injection molding compares to other common methods, such as traditional single - shot injection molding and secondary injection molding. Here is a detailed comparison:

| Comparison Items | Traditional Single - shot Injection Molding | Dual Shot Injection Molding | Secondary Injection Molding |

| Process Complexity | Relatively simple. Involves injecting a single material into a mold in one operation. | Highly complex. Requires two injection units and a specialized mold with moving or rotating mechanisms. Precise control over two different materials' injection sequences and parameters is essential. | Moderately complex. Requires two separate molds and operations. After the first injection, the part needs to be transferred to a second mold for the second injection, which adds handling steps. |

| Cost | Lower initial investment as it requires only a single - injection unit machine and a simpler mold. Lower production costs per unit for high - volume production of single - material parts. | High initial investment due to the need for a specialized dual - injection unit machine and a more complex, custom - designed mold. However, long - term production can be cost - effective for parts that require two materials, as it eliminates assembly steps. | Medium initial investment as two standard injection molding machines and two molds are needed. Higher production costs per unit due to additional handling and potential for higher defect rates during the transfer between molds. |

| Product Performance | Suitable for parts that require a single material property. Offers basic functionality and mechanical properties depending on the chosen plastic. | Can create parts with enhanced functionality by combining materials with different properties, such as strength, flexibility, and chemical resistance. Improves product durability and user experience, for example, in products with soft - touch surfaces and rigid cores. | Can add functionality to an existing part by over - molding a second material. However, the bond between the two materials may not be as strong as in dual shot injection molding, potentially affecting long - term performance. |

| Aesthetic Appeal | Limited to a single color or material appearance. | Can achieve multi - colored or multi - material appearances in a single, seamless operation, enhancing the visual appeal of the product. | Can add a second color or material, but the transition between the two may be less smooth, and there may be visible seams or lines. |

| Production Efficiency | High production speed for single - material parts. Short cycle times as there is only one injection step. | Moderate production speed due to the additional steps of re - positioning the mold and injecting a second material. However, it can be efficient for complex parts that would otherwise require multiple assembly operations. | Low production efficiency as it involves two separate injection operations and part transfer, which increases the overall cycle time. |

Yigu Technology's Perspective

As a leading non - standard plastic metal products custom supplier, Yigu Technology has a deep - seated understanding of Dual Shot Injection Molding. With years of experience in the field, we have witnessed the transformative power of this technology in creating high - quality, customized products.

Our expertise lies in tailoring dual shot injection molding processes to meet the unique needs of our clients. We have a state - of - the - art facility equipped with advanced dual - injection unit machines and a team of skilled engineers who are proficient in designing complex molds. This allows us to handle projects of varying complexities, from small - scale prototypes to large - volume production runs.

One of our key strengths is our ability to innovate. We are constantly exploring new material combinations and process improvements in dual shot injection molding. For example, we have successfully developed techniques to enhance the bond strength between different materials, resulting in more durable and reliable products. Our commitment to quality and innovation has enabled us to provide our clients with products that not only meet but exceed industry standards. Whether it's creating multi - functional components for the automotive industry or intricate parts for consumer electronics, Yigu Technology is well - positioned to leverage dual shot injection molding for the success of your projects.

FAQ

What types of materials can be used in dual shot injection molding?

Commonly used materials in dual shot injection molding include plastics like acrylonitrile - butadiene - styrene (ABS), polypropylene (PP), and silicone rubber. ABS is popular due to its good mechanical properties, heat resistance, and surface finish, making it suitable for the structural parts in products. PP is often chosen for its low cost, high chemical resistance, and good flowability, which is beneficial for the base layer in some products. Silicone rubber, on the other hand, is used for its excellent flexibility, heat resistance, and biocompatibility, for example, in products that require a soft - touch surface or in medical applications. The selection of materials depends on factors such as the desired properties of the final product, the compatibility between the two materials (both in terms of adhesion and processing conditions), and the cost - effectiveness for the specific production.

How accurate is the alignment between the two shots?

With advanced mold design and precise equipment control, the alignment between the two shots in dual shot injection molding can be highly accurate. The molds are designed with high - precision positioning mechanisms, such as guide pins and alignment slots, to ensure that the part from the first shot is in the exact position for the second injection. Modern injection molding machines are equipped with advanced control systems that can precisely control the movement of the mold and the injection process. The error in alignment can be controlled within a very small range, typically within ±0.05 - 0.1mm. This high - level accuracy ensures that the two materials are combined seamlessly, resulting in a high - quality, integrated product.

Are there any limitations to the complexity of the parts produced by dual shot injection molding?

There are limitations to the complexity of parts produced by dual shot injection molding. One of the main limiting factors is the mold design. As the part complexity increases, the mold design becomes more challenging. Complex molds may require intricate moving parts, such as multiple slides and cores, to create the necessary cavities for the two - shot process. This not only increases the cost of mold manufacturing but also the risk of mold failure during the injection process. Another factor is the material flowability. Some complex part geometries may pose difficulties for the proper flow of molten plastic during injection, especially when dealing with two different materials. This can lead to issues like incomplete filling of the mold, uneven material distribution, or poor bonding between the two materials. Additionally, the cooling process can be more complex for highly complex parts, which may result in warping or other dimensional inaccuracies.