Introduction

What is Medical Plastic Injection Molding?

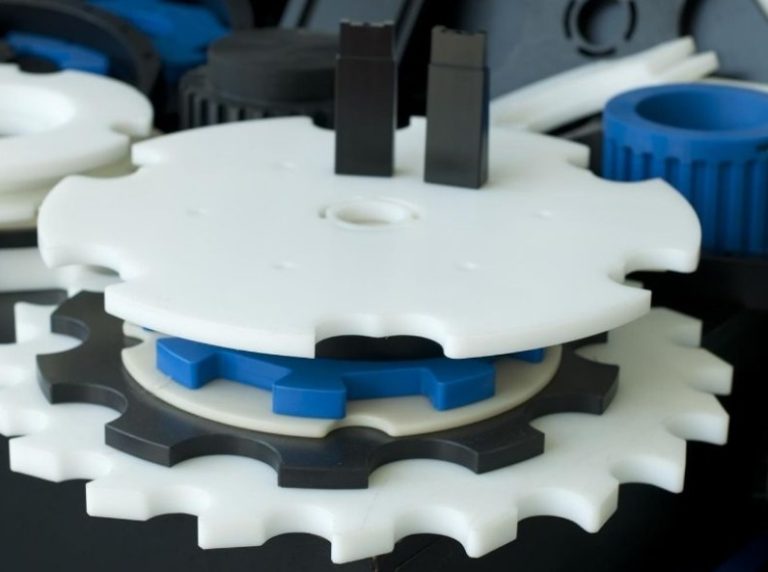

Medical plastic injection molding is a specialized manufacturing process that involves injecting molten plastic materials into a precisely designed mold cavity to create various medical components and devices. It is a highly efficient and versatile method for producing complex - shaped plastic parts with tight tolerances.

The process begins with the selection of appropriate medical - grade plastic resins. These resins are carefully chosen based on their biocompatibility, chemical resistance, durability, and other properties required for medical applications. For example, materials like polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate (PET) are commonly used in medical devices. Polycarbonate, for instance, offers excellent impact resistance and optical clarity, making it suitable for components like medical instrument lenses.

Once the plastic resin is selected, it is fed into an injection molding machine. Inside the machine, the plastic is heated to its melting point and then forced, under high pressure, into a cooled metal mold. The mold is designed to have a cavity in the exact shape of the desired medical part. After the plastic fills the mold cavity, it cools and solidifies, taking on the shape of the mold. Finally, the mold is opened, and the newly formed plastic part is ejected. This process can be repeated thousands of times, making it ideal for high - volume production.

Importance for Medical Device Manufacturers

For medical device manufacturers, medical plastic injection molding offers numerous crucial benefits.

Cost - effectiveness: Injection molding is highly efficient for high - volume production. The cost per unit decreases significantly as the production volume increases. For example, if a manufacturer needs to produce 10,000 syringe barrels, the initial investment in the injection mold tooling can be offset by the low cost of each individual barrel produced. According to industry reports, high - volume injection molding can reduce production costs by up to 30% compared to other manufacturing methods for the same quantity of parts.

Design flexibility: It allows for the creation of highly complex and precise medical components. Manufacturers can design parts with intricate internal structures, thin walls, and small features. A study by a leading medical device research firm found that over 80% of modern medical devices with complex geometries are produced using injection molding. For example, the internal channels in a catheter or the fine - tuned mechanisms in a surgical instrument can be accurately replicated through injection molding.

Material versatility: A wide range of medical - grade plastics can be used in the injection molding process. Each plastic has its own unique set of properties, enabling manufacturers to choose the material that best suits the specific requirements of the medical device. For instance, silicone is often used for its softness and biocompatibility in products like medical implants, while polypropylene is favored for its chemical resistance and low cost in items such as disposable medical containers. This material versatility allows medical device manufacturers to develop innovative products that meet the diverse needs of the healthcare industry.

Key Considerations for Medical Device Manufacturers

Material Selection

When it comes to medical plastic injection molding, material selection is of utmost importance. The chosen plastic material must meet strict biocompatibility standards. Biocompatibility ensures that the material does not cause any adverse reactions when it comes into contact with the human body, whether it's for a short - term use like a syringe or a long - term implant. For example, materials such as silicone, polyurethane, and some grades of polyethylene are highly biocompatible and are frequently used in implantable devices.

Chemical resistance is another crucial factor. Medical devices may be exposed to a variety of chemicals, including disinfectants, cleaning agents, and body fluids. A plastic material with poor chemical resistance could degrade over time, compromising the functionality and safety of the device. A study on medical device failures found that about 15% of failures were related to material degradation due to chemical exposure. For instance, if a medical storage container is not made of a chemical - resistant plastic, the substances stored inside could leach into the plastic or cause it to crack, leading to potential contamination.

Durability is also essential. Medical devices need to withstand mechanical stress, sterilization processes (such as autoclaving, which involves high - temperature and high - pressure conditions), and long - term use. High - density polyethylene (HDPE) is often used for its durability in applications like surgical instrument trays. It can endure repeated autoclaving cycles without significant loss of mechanical properties.

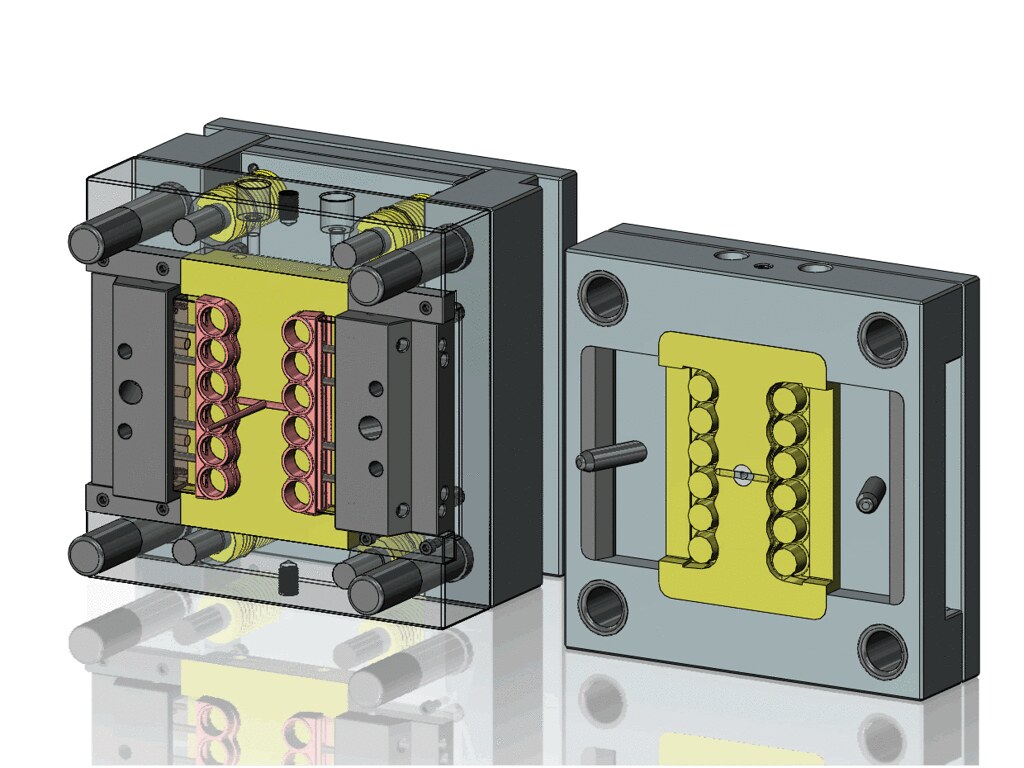

Mold Design

A well - designed mold is the key to producing high - quality medical plastic components. The mold's structure should be robust enough to withstand the high - pressure injection process. A weak mold structure could lead to deformation during injection, resulting in parts with inconsistent dimensions and poor quality. For example, if the mold walls are too thin, they may bulge under the pressure of the molten plastic, causing the final product to have an incorrect shape.

Precision in mold design is crucial, especially when it comes to the dimensions of the medical components. Medical devices often have tight tolerance requirements. A study in the medical device manufacturing industry showed that over 90% of precision - critical medical parts require a dimensional tolerance of ±0.05mm or less. Molds need to be designed and manufactured with extremely high precision to meet these requirements. For instance, in the production of micro - fluidic chips for medical diagnostics, the channels in the mold must be fabricated with nanometer - level precision to ensure accurate fluid flow within the chip.

The mold should also be designed for easy demolding. Smooth surfaces and proper draft angles (usually between 0.5 - 2 degrees depending on the plastic material) are necessary to prevent the part from getting stuck in the mold during ejection. If a part is difficult to demold, it can be damaged, or the production process may be interrupted, leading to increased costs and reduced productivity.

Quality Control and Regulatory Compliance

Quality control is a continuous process in medical plastic injection molding. It starts from the incoming inspection of raw materials. Every batch of plastic resin should be tested for its physical and chemical properties to ensure it meets the specified standards. In - process inspections are also crucial. Regular checks are made during the injection molding process to monitor parameters such as injection pressure, temperature, and cycle time. Any deviation from the set values could indicate a potential problem with the product quality. For example, if the injection pressure is too low, the plastic may not fully fill the mold cavity, resulting in incomplete parts.

Final product inspections involve thorough visual and dimensional inspections. Each part is examined for surface defects like scratches, cracks, and voids. Dimensional measurements are taken using precision measuring instruments to ensure that the parts meet the design specifications. According to industry best practices, a minimum of 10% of the production batch should be randomly sampled for detailed inspections.

Regulatory compliance is non - negotiable in the medical device industry. Medical plastic injection - molded products must comply with various international and national regulations, such as the European Union's Medical Device Directive (MDD) and the US Food and Drug Administration (FDA) regulations. These regulations cover aspects like product safety, effectiveness, and manufacturing processes. Non - compliance can result in severe consequences, including product recalls, fines, and damage to the manufacturer's reputation. For example, in 2020, a medical device manufacturer faced a major recall and significant financial losses when its injection - molded products were found to be non - compliant with FDA regulations regarding biocompatibility testing.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the critical nature of medical plastic injection molding. We recognize that the challenges in material selection, mold design, and quality control are not to be taken lightly. Our team of experts is well - versed in handling complex material requirements, ensuring that the chosen plastics meet the highest biocompatibility, chemical resistance, and durability standards.

When it comes to mold design, we use advanced CAD/CAM technologies to create molds with utmost precision. Our molds are engineered to withstand the rigors of high - pressure injection while maintaining the tightest tolerances. We also have a comprehensive quality control system in place, from raw material inspection to final product testing, to ensure full compliance with regulatory requirements. Yigu Technology is committed to providing customized solutions that meet the unique needs of medical device manufacturers, helping them bring high - quality and reliable medical products to the market.

FAQ

What are the most common materials used in medical plastic injection molding?

Common materials include silicone, known for its excellent biocompatibility, softness, and flexibility, making it suitable for implants and tubing. Polyurethane offers a good balance of mechanical properties, biocompatibility, and chemical resistance, often used in catheters. Polypropylene is cost - effective, has good chemical resistance, and is widely used in disposable medical products like syringes and containers. Polycarbonate provides high strength, impact resistance, and optical clarity, which is useful for components such as medical instrument lenses.

How can we ensure the quality of medical plastic injection - molded products?

Firstly, conduct strict raw material testing. Test the incoming plastic resins for properties like biocompatibility, melt flow index, and molecular weight to ensure they meet the required standards. During the production process, closely monitor parameters such as injection pressure (usually maintained within a specific range, e.g., 50 - 200 MPa depending on the material and product), temperature (ranging from 150 - 300°C), and cycle time. After production, perform comprehensive inspections. Use visual inspection to check for surface defects, and employ precision measuring tools like coordinate measuring machines (CMMs) to verify dimensional accuracy.

What are the main differences between medical and non - medical plastic injection molding?

In terms of material requirements, medical plastic injection molding demands biocompatible materials that can withstand sterilization, while non - medical applications have more relaxed material criteria. For precision standards, medical components often require extremely tight tolerances, sometimes within ±0.01mm, compared to relatively looser tolerances in non - medical products. Quality control is more rigorous in medical molding, with in - depth testing at every stage, while non - medical molding may have less strict inspection procedures. Finally, medical plastic injection molding must comply with strict regulations like FDA and MDD, while non - medical molding is not subject to such specific medical - related regulations.