Introduction

In modern manufacturing, the plastic moulding process plays a pivotal role, serving as the cornerstone for the production of a vast array of products that permeate every aspect of our daily lives. From the tiny components within our electronic devices to the large, durable structures in the automotive and aerospace industries, plastic moulding techniques are employed to transform raw plastic materials into precisely engineered and functional parts. This article delves deep into the world of plastic moulding, exploring its various types, the materials involved, the essential equipment required, and the critical aspects of quality control. Whether you are an industry professional seeking to expand your knowledge or a novice interested in understanding the inner workings of plastic manufacturing, this comprehensive guide will provide valuable insights and practical information to help you navigate the complexities of the plastic moulding process.

Types of Plastic Moulding Process

Injection Moulding

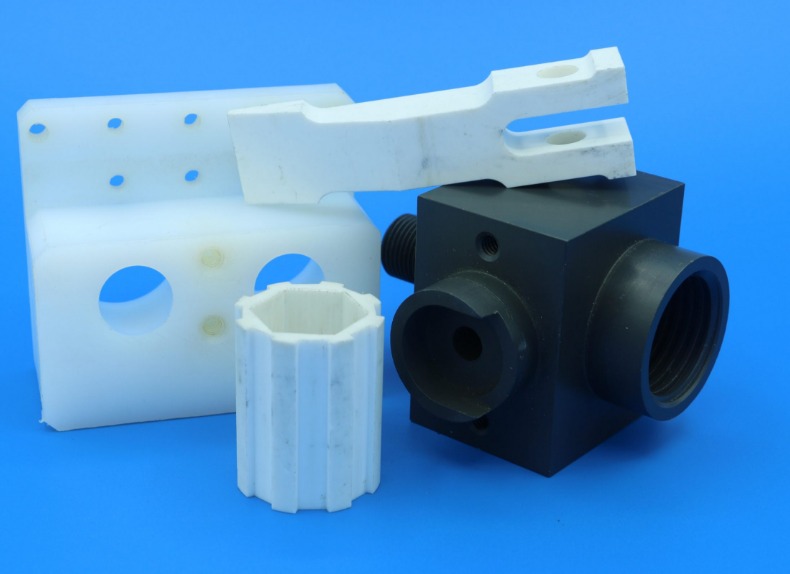

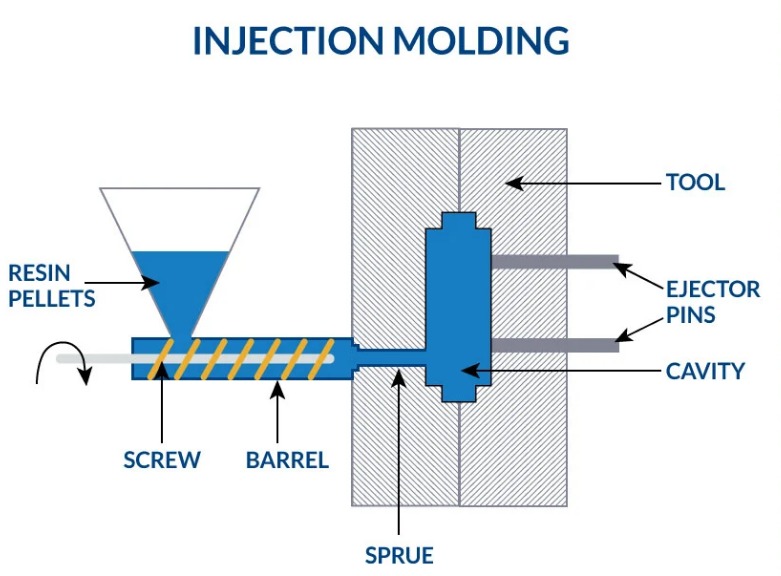

Injection moulding is one of the most widely used plastic moulding processes. The working principle is relatively straightforward yet highly efficient. First, plastic pellets are fed into a heated barrel. Here, they are melted into a viscous liquid state through the application of heat. A reciprocating screw then forces this molten plastic under high pressure into a precisely designed metal mould cavity. Once the cavity is filled, the plastic is allowed to cool and solidify, taking on the exact shape of the mould. This process is incredibly fast, with cycle times often ranging from a few seconds to a couple of minutes, depending on the complexity and size of the part.

This method finds extensive applications across various industries. In the automotive sector, it is used to manufacture a plethora of components, such as dashboard parts, interior trims, and even some engine components. For example, the intricate and detailed interior door panels of many cars are produced through injection moulding. In the electronics industry, the outer casings of smartphones, tablets, and laptops are commonly made using this process. The high precision achievable in injection moulding ensures that these products have a sleek and seamless appearance, while also meeting strict dimensional requirements.

One of the key advantages of injection moulding is its high production rate. It can produce large volumes of parts in a short period, making it ideal for mass production. Additionally, it offers excellent dimensional accuracy, with tolerances often as low as ±0.05 mm. This precision allows for the creation of complex geometries and fine details. However, it also has some limitations. The initial investment in moulds can be substantial, often costing tens of thousands to hundreds of thousands of dollars, depending on the complexity. This makes it less suitable for small - batch production.

Blow Moulding

Blow moulding is a process specifically designed for the production of hollow plastic products. The basic principle involves heating a plastic parison (a tube - like piece of plastic) until it becomes soft and pliable. This softened parison is then placed inside a mould cavity. Compressed air is blown into the parison, causing it to expand and conform to the shape of the mould cavity. Once the plastic has cooled and solidified, the mould is opened, and the finished hollow product is removed.

This process is commonly used in the production of plastic bottles, which are ubiquitous in the beverage, food, and personal care industries. For instance, the PET bottles that hold our favorite soft drinks or bottled water are typically made through blow moulding. It is also used to create toys, such as inflatable toys and some hollow plastic figurines. In the industrial sector, large - scale blow moulding is used to produce fuel tanks for vehicles and industrial containers.

One of the main advantages of blow moulding is its ability to produce hollow products with a uniform wall thickness. This results in products that are lightweight yet durable. The process also allows for a high degree of design flexibility, as the shape of the mould can be customized to create a wide variety of products. However, compared to injection moulding, the dimensional accuracy of blow - moulded products is generally lower, with tolerances typically in the range of ±0.5 mm.

Compression Moulding

Compression moulding is a process mainly used for the production of thermosetting plastic products. In this process, a pre - measured amount of raw plastic material, often in the form of a pre - shaped pellet or sheet, is placed into a heated mould cavity. The mould is then closed, and pressure is applied. As the plastic is heated and compressed, it begins to flow and fill the mould cavity. During this process, a chemical reaction occurs in thermosetting plastics, causing them to cure and harden permanently. Once the curing process is complete, the mould is opened, and the finished product is removed.

This process is commonly used in the manufacturing of electrical appliances, where components such as switch housings, plug sockets, and some parts of electronic device enclosures are made. It is also used in the production of tableware, like melamine - based plates and bowls. In the aerospace industry, compression moulding is used to create some structural components due to the high strength - to - weight ratio of the thermosetting plastics used.

The advantages of compression moulding include the ability to produce parts with high strength and heat resistance, which is characteristic of thermosetting plastics. It also allows for the incorporation of fillers and reinforcements easily, which can further enhance the mechanical properties of the final product. However, the process has a relatively long cycle time compared to injection moulding, often taking several minutes to complete. This can limit its productivity for high - volume production.

Rotational Moulding

Rotational moulding, also known as rotomoulding, is a unique plastic moulding process. In this method, a measured amount of powdered or liquid plastic is placed inside a hollow mould. The mould is then simultaneously rotated (usually in two perpendicular axes) and heated in an oven. As the mould rotates, the plastic material gradually melts and coats the inner surface of the mould due to the effects of gravity and centrifugal force. Once the plastic has uniformly coated the mould surface, the mould is cooled, either by air or water, causing the plastic to solidify into the desired shape.

Rotational moulding is well - suited for the production of large - scale and complex - shaped plastic products. Examples include large storage tanks, which can hold thousands of liters of liquid and are used in industries such as water treatment, agriculture, and chemical storage. Outdoor furniture, like plastic chairs, tables, and planters, are also commonly made through rotational moulding. The process allows for the creation of seamless, one - piece products with a uniform wall thickness.

One of the significant advantages of rotational moulding is its ability to produce large, complex - shaped products without the need for multiple parts or joints. This results in products that are more durable and have a better aesthetic appearance. It also has relatively low tooling costs compared to injection moulding, making it more accessible for small - to - medium - scale production runs. However, the production cycle in rotational moulding can be longer compared to some other processes, and the surface finish may not be as smooth as that of injection - moulded products.

Materials Used in Plastic Moulding

Common Plastic Materials

- Polyethylene (PE): PE is one of the most widely used plastics globally, known for its versatility. It has a relatively low density, which contributes to its lightweight nature. This plastic offers excellent chemical resistance, making it suitable for applications where it may come into contact with various chemicals. For example, in the packaging industry, it is used to make containers for storing chemicals, as well as food - packaging materials like plastic bags and food containers. Its low - cost production also makes it an attractive option for mass - produced items. However, PE has a relatively low melting point, which limits its use in high - temperature applications. HDPE (High - Density Polyethylene) is stiffer and more durable, often used in products like milk jugs and plastic pipes, while LDPE (Low - Density Polyethylene) is more flexible and is commonly used in plastic films and some types of plastic bags.

- Polypropylene (PP): PP is a thermoplastic polymer with good heat resistance, which allows it to maintain its shape and properties at higher temperatures compared to some other plastics. It has a high strength - to - weight ratio, making it ideal for applications where lightweight yet strong materials are required. In the automotive industry, PP is used to manufacture interior components such as dashboard parts, door panels, and seat covers. It is also widely used in the production of household items like plastic storage containers, which can be safely used in microwaves due to its heat - resistant properties. PP has excellent chemical resistance, especially to organic solvents. But it is more prone to oxidation and UV degradation, so it may require additives to enhance its durability in outdoor applications.

- Polyvinyl Chloride (PVC): PVC is a versatile plastic with a wide range of applications. It has good mechanical properties, including high strength and rigidity in its rigid form. Rigid PVC is commonly used in the construction industry for pipes, window frames, and siding. It offers excellent corrosion resistance, making it suitable for use in plumbing systems where it may be exposed to water and various chemicals. In its flexible form, PVC, often with the addition of plasticizers, is used to make products such as cables, flooring, and some types of clothing. However, PVC has some environmental concerns. During its production and disposal, it can release harmful substances. Also, it has relatively poor heat stability, and special stabilizers are needed to prevent degradation during processing and use.

- Polystyrene (PS): PS is a transparent plastic that is often used for applications where optical clarity is required, such as in the production of disposable cups, food containers, and some types of packaging. It has good insulation properties, both thermal and electrical, making it useful in the electronics industry for components like insulating parts. Expanded polystyrene (EPS), which is a foamed form of PS, is widely used in packaging for fragile items and in construction as insulation material due to its low density and good shock - absorbing properties. But PS is brittle and not suitable for applications that require high impact resistance.

Material Selection Considerations

- Product Performance Requirements:

- Mechanical Properties: If the product needs to withstand high mechanical stress, materials like nylon (PA) or polycarbonate (PC) might be more suitable. Nylon has excellent abrasion resistance and high tensile strength, making it ideal for parts such as gears and bearings. PC, on the other hand, offers high impact resistance, which is crucial for products like safety helmets and some types of electronic device housings.

- Thermal Properties: For high - temperature applications, materials with high heat resistance should be chosen. For example, in the aerospace industry, where components are exposed to extreme temperatures, materials like polyimide (PI) are used. PI can withstand temperatures up to several hundred degrees Celsius without significant degradation.

- Chemical Resistance: When the product will be in contact with chemicals, a plastic with appropriate chemical resistance must be selected. For instance, if it will be exposed to strong acids or alkalis, materials like PTFE (Polytetrafluoroethylene) are highly resistant and would be a good choice.

- Cost: The cost of the plastic material is a significant factor, especially for mass - produced items. Commodity plastics like PE and PP are generally less expensive, making them suitable for applications where cost - effectiveness is a priority, such as in the production of disposable products. However, for high - performance products where cost is not the primary concern, more expensive engineering plastics can be used.

- Processing Performance: Some plastics are easier to process than others. For example, PE and PP have good flow properties when melted, which makes them suitable for injection moulding processes as they can easily fill complex mould cavities. In contrast, some high - performance plastics may have high melt viscosities, which can make processing more challenging and may require specialized equipment and techniques.

Equipment for Plastic Moulding

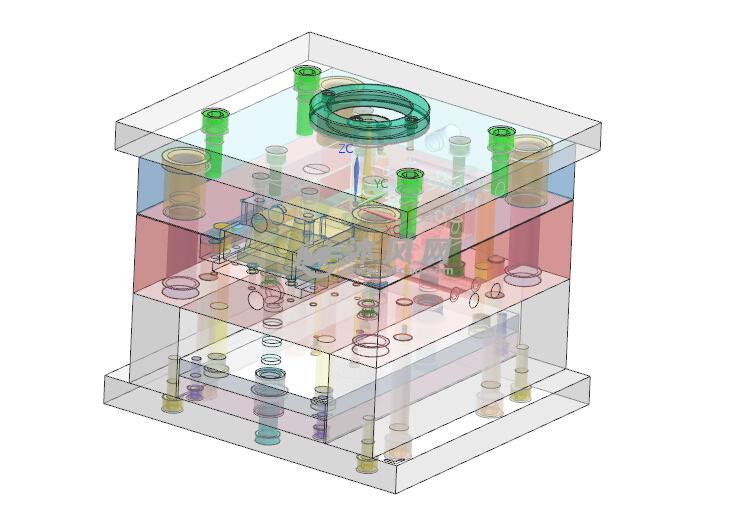

Injection Moulding Machines

Injection moulding machines are the workhorses of the injection moulding process. They typically consist of several key components. The injection system is responsible for melting the plastic and injecting it into the mould. It includes a hopper for feeding plastic pellets, a heated barrel where the plastic is melted, and a reciprocating screw. The screw not only rotates to convey and mix the plastic but also moves forward to inject the molten plastic into the mould cavity with high pressure. For example, in a medium - sized injection moulding machine, the injection pressure can reach up to 150 - 200 MPa, depending on the requirements of the plastic material and the product design.

The Mold closing system (clamping system) is equally important. It holds the mould closed during the injection and cooling phases to prevent the molten plastic from escaping. This system usually comprises a stationary platen, a moving platen, and a mechanism to generate the clamping force, such as hydraulic cylinders or toggle mechanisms. The clamping force can range from a few tons to thousands of tons, depending on the size of the mould and the projected area of the part being moulded. For instance, for a large - scale automotive component, a clamping force of over 1000 tons might be required.

When operating an injection moulding machine, precise control of parameters is crucial. The temperature of the barrel needs to be carefully set according to the plastic material being used. For example, for polyethylene, the barrel temperature is usually set in the range of 160 - 220°C, while for polycarbonate, it is around 270 - 320°C. The injection speed and pressure also need to be adjusted based on the complexity of the part. For parts with thin walls, a higher injection speed may be required to ensure complete filling of the mould cavity.

Blow Moulding Equipment

The key components of blow moulding equipment include an extruder, which is similar to the one in the injection system of an injection moulding machine. The extruder melts the plastic and forms it into a parison. It typically consists of a screw, a barrel, and a heating system. The screw rotates to convey the plastic pellets, which are melted by the heat from the barrel. The quality of the extruder greatly affects the performance of the blow - moulding process. A high - quality extruder can ensure a stable and uniform melt flow, which is essential for producing high - quality hollow products.

The mould in blow moulding is designed to form the shape of the final product. It is usually a two - part or multi - part structure that can be opened and closed. The mould has a cavity that matches the outer shape of the product, and it also has provisions for the introduction of compressed air. The material of the mould can vary, with aluminum and steel being common choices. Aluminum moulds are lightweight and have good thermal conductivity, which can speed up the cooling process, while steel moulds are more durable and suitable for high - volume production.

During the blow - moulding process, the extruder first creates a parison. This parison is then quickly transferred to the mould cavity. Once in the cavity, compressed air is introduced through a nozzle or a passage in the mould. The pressure of the compressed air is typically in the range of 0.2 - 1 MPa, depending on the size and shape of the product. The air pressure causes the parison to expand and conform to the shape of the mould, creating the hollow product.

Compression Moulding Presses

Compression moulding presses are designed to apply pressure and heat to the plastic material in the mould. They usually have a frame that provides the structural support for the entire machine. The frame is made of strong materials such as steel to withstand the high pressures involved in the compression process. Inside the press, there are platens that hold the mould. One platen is stationary, while the other is movable. The movable platen is driven by a hydraulic or mechanical system to apply the required pressure to the mould.

The working principle of a compression moulding press is relatively straightforward. After the plastic material is placed in the mould, the press closes, and the platens exert pressure on the mould. At the same time, the mould is heated, either by electric heaters embedded in the platens or by other heating methods. The combination of heat and pressure causes the plastic to flow, fill the mould cavity, and undergo a chemical reaction (in the case of thermosetting plastics) to cure and harden.

When choosing a compression moulding press, several factors need to be considered. The tonnage of the press, which indicates the maximum pressure it can exert, should match the requirements of the product. For small - scale production of simple parts, a press with a lower tonnage, say 50 - 100 tons, may be sufficient. However, for large - scale production of complex or thick - walled parts, a press with a higher tonnage, such as 500 - 1000 tons, may be necessary. The size of the platens should also be appropriate to accommodate the size of the mould.

Rotational Moulding Machinery

Rotational moulding machinery is specifically designed to carry out the rotational moulding process. It has a mould - holding mechanism that can rotate the mould in multiple axes, typically two perpendicular axes. This rotation is crucial for ensuring that the plastic material inside the mould evenly coats the inner surface. The mould - holding mechanism is usually driven by motors, and the speed of rotation can be adjusted according to the requirements of the product and the plastic material.

The machinery also includes an oven for heating the mould and the plastic material. The oven can use various heating methods, such as gas - fired heating or electric heating. The temperature inside the oven needs to be carefully controlled to ensure that the plastic melts and flows properly. For most common plastic materials used in rotational moulding, such as polyethylene, the oven temperature is typically set in the range of 250 - 350°C.

Once the plastic has coated the mould surface and the product has taken shape, the mould needs to be cooled. The cooling system in rotational moulding machinery can be either air - cooled or water - cooled. Air - cooling is a simpler method, but it may take longer to cool the mould and the product. Water - cooling, on the other hand, can speed up the cooling process, but it requires more complex equipment and careful management to prevent water leakage and ensure uniform cooling. The operation of rotational moulding machinery requires skilled operators who can accurately control the rotation speed, heating temperature, and cooling time to produce high - quality products.

Quality Control in Plastic Moulding

Importance of Quality Control

Quality control is the linchpin of the plastic moulding process, exerting a profound influence on every aspect of production. First and foremost, it ensures that the final plastic products meet the highest standards of quality. In industries such as medical devices and aerospace, where product failure can have catastrophic consequences, strict quality control measures are non - negotiable. For example, in the production of medical syringes, even the slightest deviation in the moulding process could lead to issues like inaccurate dosing or difficulty in injection, which may directly endanger patients' lives.

Secondly, effective quality control significantly reduces the rate of defective products. By closely monitoring the production process and promptly identifying and rectifying issues, manufacturers can avoid producing large quantities of faulty products. This not only saves on the cost of raw materials but also reduces the time and effort wasted on rework or disposal. For instance, in a plastic toy manufacturing plant, through rigorous quality control, the defect rate can be reduced from 5% to 1%, resulting in substantial cost savings over time.

Moreover, quality control contributes to enhanced production efficiency. When quality issues are detected early, production lines can be adjusted immediately, minimizing downtime caused by equipment failures or the need to scrap large batches of products. This allows for a more continuous and efficient production process, increasing overall output.

Quality Control Methods

- (First - Article Inspection): This is a crucial step at the beginning of production. After setting up the moulding equipment and preparing the materials, the first product or a small batch of the initial products is thoroughly inspected. The inspection includes a detailed check of the product's dimensions, which are measured using precision measuring tools such as calipers or micrometers to ensure they match the design specifications. The appearance is also closely examined for any defects like cracks, bubbles, or uneven surfaces. Functionality tests are carried out if applicable. For example, in the production of plastic connectors, the first - article inspection would involve checking the fit and electrical conductivity of the connectors. This method helps to identify any potential issues with the mould, equipment settings, or materials at the start, preventing the production of a large number of non - conforming products.

- (In - Process Inspection): During the production run, regular inspections are conducted at specific intervals. A sample of products is randomly selected from the production line. The inspection focuses on maintaining consistency in product quality. Process parameters such as temperature, pressure, and injection speed are also verified to ensure they are within the set ranges. In an injection moulding factory producing plastic cups, the inspector may check the wall thickness, diameter, and overall shape of the cups during in - process inspection. This helps to detect any gradual changes in the production process that could lead to quality problems, such as a slow decline in the quality of the mould due to wear and tear.

- (Sampling Inspection): A statistical sampling method is used to assess the quality of a batch of products. A representative sample is randomly selected from a large production batch. The sample size is determined based on statistical principles and the acceptable quality level (AQL). For example, if producing 10,000 plastic parts, a sample of 100 parts may be selected for inspection according to the AQL standard. The sample is then inspected for various quality characteristics, including dimensions, appearance, and physical properties. This method is cost - effective and time - efficient, allowing manufacturers to make inferences about the quality of the entire batch based on the sample inspection results.

Measuring and Monitoring Tools

- (Calipers): Calipers are one of the most commonly used measuring tools in plastic moulding quality control. They are available in different types, such as vernier calipers and digital calipers. These tools are used to measure linear dimensions of plastic products, such as length, width, and thickness. For example, when measuring the thickness of a plastic sheet, a digital caliper can provide accurate readings up to 0.01 mm. They are easy to use and can quickly provide measurements on the production line, enabling operators to check if the product dimensions are within the specified tolerances.

- (Projectors): Projectors are used to measure the shape and profile of plastic products. They work by projecting an image of the product onto a screen or a measuring grid. The projected image is then compared with the design blueprint. This is particularly useful for products with complex shapes or intricate details. For instance, in the production of plastic gears, the projector can accurately measure the tooth profile and pitch diameter, ensuring that the gears are manufactured to the correct specifications.

- (Coordinate Measuring Machines, CMMs): CMMs are highly accurate measuring devices that can measure the three - dimensional coordinates of a part. They use probes to touch the surface of the plastic product at multiple points and calculate the precise position of these points in three - dimensional space. CMMs can measure complex geometries with high precision, typically with an accuracy of ±0.001 mm. They are often used for high - precision plastic parts, such as those in the aerospace or automotive industries. For example, in the production of plastic engine components, CMMs can verify the dimensional accuracy of the part, ensuring proper fit and functionality within the engine system.

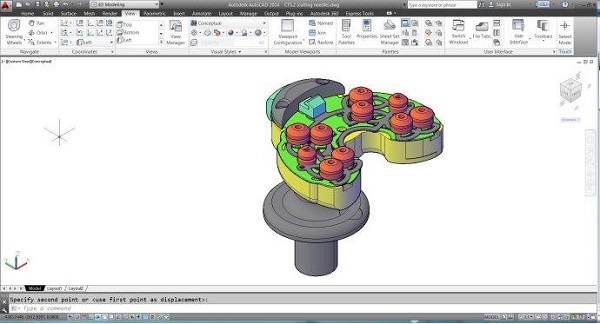

Choosing the Right Plastic Moulding Company

When it comes to plastic molding, choosing the right company is crucial. It can determine successful product releases and costly failures. When choosing a molding company, several factors need to be considered, such as their expertise in a specific industry, production capacity, equipment capability, quality control standards, and sustainability practices.

An important step in choosing a suitable company is due diligence. This involves thoroughly researching potential companies to ensure they meet your requirements and have a good reputation in the industry. It is also important to ask for references or case studies of similar projects they have successfully completed.

Negotiations with potential companies should focus on key areas such as pricing, delivery schedules, and payment terms. However, price should not be the sole criterion for selecting suppliers, as lower prices may bring hidden costs that ultimately affect quality or delivery time.

Once you have identified a suitable candidate based on these factors, it is important to translate any agreement into contract form so that both parties understand their expectations for each other within the agreed time frame. Before partnering with a new supplier, carefully considering all these factors is likely to establish a successful partnership that benefits everyone through shared growth opportunities!

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of the plastic moulding process. With years of experience in the industry, we have been at the forefront of innovating in plastic moulding techniques. We continuously explore new ways to optimize the process, whether it's through improving the efficiency of injection moulding or enhancing the precision of rotational moulding.

Quality control is the core of our production philosophy. We have a rigorous quality control system in place, which includes multiple inspection procedures from raw material procurement to the final product. Our state - of - the - art measuring and monitoring tools, such as high - precision CMMs, ensure that every product we deliver meets or exceeds the industry standards. We believe that by focusing on innovation and quality in the plastic moulding process, we can provide our customers with high - quality, customized products that perfectly meet their specific needs.

FAQ

What are the common quality issues in plastic moulding and how to solve them?

- (Flash): This occurs when plastic leaks out between the mould halves. It can be solved by adjusting the clamping force of the moulding machine, checking for any damage or wear in the mould parting line, and ensuring proper mould alignment.

- (Bubbles): Bubbles inside the plastic product may be caused by trapped air or moisture in the plastic material. To solve this, drying the plastic material properly before processing and optimizing the injection speed and pressure to avoid air entrapment can be effective.

- (Deformation): Uneven cooling or excessive internal stress can lead to product deformation. Implementing proper cooling systems, such as using cooling channels in the mould more effectively, and adjusting the processing parameters to reduce internal stress can help solve this problem.

Conclusion

In short, plastic molding technology is universal and has been widely used in the manufacturing industry. According to application requirements, various types of plastic molding processes can be used, such as injection molding, blow molding, rotary molding, etc. The materials used for plastic molded parts also vary due to factors such as strength, flexibility, or transparency. Monitoring process parameters such as temperature and pressure is crucial to ensure quality control during the production process. Sustainable measures such as plastic material recycling should also be considered to reduce waste generation. By optimizing these factors in the plastic molding process, with a focus on quality control and sustainability practices, manufacturers can produce high-quality products while minimizing costs and environmental impact.