If you’re wondering what rubber injection is and how it works for manufacturing, you’re in the right place. Simply put, rubber injection is a precision manufacturing process that injects molten rubber into a closed mold cavity, where it cools, cures, and takes the shape of the mold. It’s widely used to produce consistent, high-quality rubber parts—from small O-rings to large industrial seals—because it offers better control over part dimensions, reduces waste, and speeds up production compared to older methods like compression molding. Whether you’re a product designer, manufacturer, or someone curious about how everyday rubber parts are made, this guide breaks down everything you need to know, from the basics to advanced tips.

How Rubber Injection Works: A Step-by-Step Breakdown

Understanding the rubber injection process is key to deciding if it’s right for your project. Unlike compression molding (where pre-formed rubber “charges” are pressed into molds), rubber injection uses heat and pressure to push liquid rubber into every corner of a mold. Here’s a detailed, easy-to-follow breakdown:

- Material Preparation: First, raw rubber (often in the form of pellets or sheets) is loaded into a hopper on the injection machine. Additives like vulcanizing agents (to harden the rubber) or colorants may be mixed in at this stage to meet specific part requirements. For example, if making heat-resistant gaskets for car engines, a high-temperature rubber like EPDM would be mixed with a sulfur-based vulcanizing agent.

- Melting (Plastication): The rubber moves from the hopper into a heated barrel, where a rotating screw applies pressure and heat. The barrel temperature is carefully controlled—usually between 120°C and 180°C (248°F to 356°F), depending on the rubber type—to melt the rubber without burning it. This molten rubber is called “compound.”

- Injection: Once the compound is ready, the screw pushes it through a nozzle and into the mold cavity (a metal tool shaped like the final part). Pressure here is critical—typically 10 to 100 MPa (1,450 to 14,500 psi)—to ensure the rubber fills every detail of the mold, even tiny grooves or holes.

- Curing (Vulcanization): The mold is kept at a constant temperature (often 150°C to 200°C / 302°F to 392°F) for a set time (called “dwell time”). During this stage, the vulcanizing agents react, cross-linking the rubber molecules and hardening the compound into a solid, durable part. For a small O-ring, dwell time might be 30 seconds; for a large industrial seal, it could be 5+ minutes.

- Demolding & Post-Processing: After curing, the mold opens, and the part is removed. Some parts may need minor post-processing—like trimming excess rubber (called “flash”) or adding surface finishes—before they’re ready for use.

A real-world example: A medical device manufacturer uses this process to make silicone syringe plungers. The precision of injection ensures each plunger has the exact same diameter, which is critical for accurate drug dosing. Without this consistency, the plungers could leak or deliver incorrect amounts of medication.

Key Rubber Types Used in Injection Molding

Not all rubbers work for injection molding—some are too stiff or don’t flow well when melted. Below are the most common types, along with their properties, uses, and why they’re a good fit for the process.

| Rubber Type | Key Properties | Common Applications | Why It Works for Injection |

| Silicone Rubber | Heat-resistant (-60°C to 230°C), flexible, non-toxic | Medical implants, kitchen utensils, gaskets | Flows easily; cures quickly at mold temps |

| EPDM | Weather-resistant, ozone-proof, low cost | Automotive door seals, roofing gaskets | Maintains flexibility in extreme temps; good flow |

| Nitrile (NBR) | Oil-resistant, durable, good tensile strength | Fuel hoses, industrial O-rings, gloves | Bonds well in molds; holds shape under pressure |

| Neoprene (CR) | Chemical-resistant, flame-retardant | Wetsuits, electrical insulation, pump parts | Stable at high injection temps; low shrinkage |

| Butyl Rubber | Air-tight, vibration-dampening | Tire inner tubes, medical stoppers | High flow rate; minimal waste during injection |

Pro Tip: Choosing the right rubber depends on your part’s end use. For example, if you’re making a part that will be exposed to gasoline (like a fuel line), nitrile is a must—silicone would break down in oil. A manufacturer I worked with once made the mistake of using EPDM for an oil filter seal; the seals leaked within weeks, and they had to retool with nitrile, costing thousands in delays.

Rubber Injection vs. Other Molding Methods: Which Is Better?

If you’re deciding between rubber injection and other methods (like compression or transfer molding), it’s important to compare their strengths and weaknesses. Below is a clear breakdown to help you choose:

1. Rubber Injection vs. Compression Molding

- Compression Molding: Uses pre-cut rubber “charges” that are pressed into an open mold with heat and pressure. It’s older, simpler, and cheaper for small production runs (fewer than 1,000 parts).

- Rubber Injection: As we’ve covered, uses molten rubber injected into a closed mold.

- Key Differences:

- Consistency: Injection produces parts with tighter tolerances (±0.02mm vs. ±0.1mm for compression). This is crucial for parts like precision seals.

- Waste: Injection generates 5-10% waste (mostly flash), while compression can waste up to 20% (unused rubber from charges).

- Speed: Injection cycles are 20-50% faster. For example, a compression mold might take 2 minutes per part; injection takes 1 minute.

- Cost: Injection has higher upfront costs (molds are more complex), but lower per-unit costs for large runs (10,000+ parts).

Case Study: A automotive supplier switched from compression to injection for making door seals. Their production time dropped by 35%, and they saved $20,000 annually on material waste.

2. Rubber Injection vs. Transfer Molding

- Transfer Molding: A middle ground—rubber is melted in a “pot” and pushed into the mold with a plunger (not a screw). It’s better than compression for complex parts but less efficient than injection.

- Key Differences:

- Complexity: Injection can handle more detailed molds (e.g., parts with tiny holes or undercuts) because the screw provides more pressure to fill cavities.

- Cycle Time: Injection cycles are 15-30% faster than transfer.

- Maintenance: Transfer molds have more moving parts (like pots and plungers) that need frequent cleaning; injection molds are simpler to maintain.

For most modern manufacturing, injection is the best choice if you need high volume, precision, or complex parts. Compression is better for small runs or simple parts (like basic gaskets), and transfer is rarely used today except for legacy projects.

Critical Factors for Successful Rubber Injection

Even with the right process and materials, mistakes can happen. Below are the most important factors to monitor to ensure your rubber injection projects go smoothly:

1. Temperature Control

Both the barrel (where rubber is melted) and the mold (where it cures) need precise temperature control. If the barrel is too hot, the rubber can burn or degrade; too cold, and it won’t flow properly. For example, silicone rubber melts best at 160°C—if the barrel hits 180°C, the silicone may turn brittle, leading to cracked parts. Most modern machines use digital thermostats with ±1°C accuracy to avoid this.

2. Pressure Settings

Injection pressure (how hard the screw pushes the rubber) and hold pressure (pressure maintained while the mold fills) are critical. Too much pressure can damage the mold or cause flash (excess rubber); too little, and the mold won’t fill completely. A rule of thumb: For small parts (like O-rings), use 30-50 MPa; for large parts (like industrial seals), use 70-100 MPa. Always test with a few sample parts first to adjust pressure.

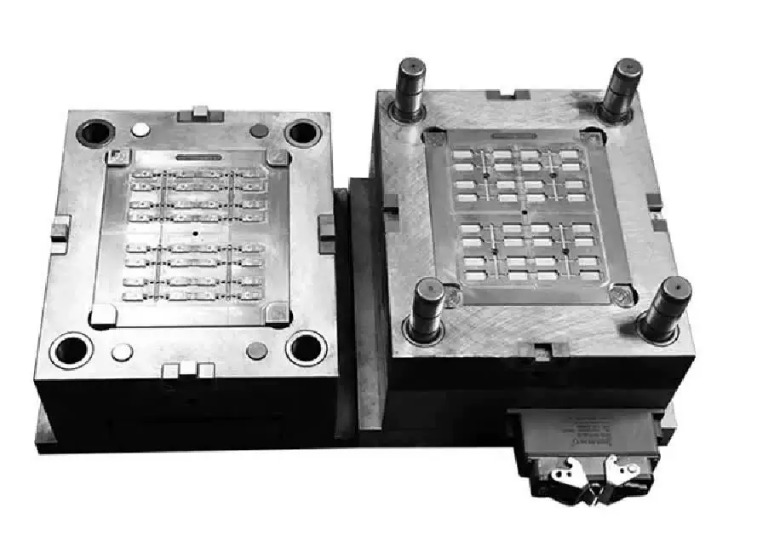

3. Mold Design

A well-designed mold is the foundation of good parts. Key mold features to consider:

- Vents: Small channels that let air escape from the mold. Without vents, air bubbles get trapped in the rubber, causing holes or weak spots.

- Gate Design: The opening where rubber enters the mold. A poorly placed gate can leave marks on the part or cause uneven filling.

- Cooling Channels: Paths for water to flow around the mold, ensuring even curing. Uneven cooling leads to warped parts.

Example: A client once brought me a batch of warped silicone gaskets. After checking, I found their mold had no cooling channels—one side of the mold was 10°C hotter than the other, so the rubber cured unevenly. Adding cooling channels fixed the problem.

4. Material Quality

Using low-quality or contaminated rubber will ruin your parts. Always buy rubber from reputable suppliers and check for:

- Consistency: The rubber should have the same texture and density throughout. Lumps or inconsistencies mean it was stored improperly.

- Expiration Dates: Vulcanizing agents in rubber expire—old rubber won’t cure properly, leading to soft, sticky parts.

Industry Trends & Data in Rubber Injection

Rubber injection is constantly evolving, driven by new technologies and demand for more sustainable, efficient manufacturing. Below are the latest trends and key data to keep you informed:

1. Market Growth

The global rubber injection molding market is growing rapidly. According to Grand View Research, the market size was \(XX billion in 2024 and is expected to reach \)XX billion by 2030, with a CAGR (annual growth rate) of 5.2%. This growth is fueled by demand from the automotive, medical, and electronics industries—all of which need precision rubber parts.

2. Sustainability Trends

More manufacturers are adopting eco-friendly practices in rubber injection:

- Recycled Rubber: Some companies now use recycled rubber (from old tires or scrap parts) mixed with virgin rubber. This reduces waste and lowers costs—recycled rubber is 20-30% cheaper than virgin rubber.

- Energy-Efficient Machines: New injection machines use 15-20% less energy than models from 10 years ago, thanks to better insulation and variable-speed motors.

- Water-Based Coolants: Traditional coolants use chemicals; water-based coolants are non-toxic and easier to dispose of.

3. Automation & AI

Automation is becoming common in rubber injection:

- Robotic Demolding: Robots can remove parts from the mold 24/7, reducing labor costs and human error. A study by the Rubber Manufacturers Association found that automated lines produce 30% fewer defective parts than manual lines.

- AI Monitoring: Some machines use AI to track temperature, pressure, and cycle time in real time. If a parameter goes out of range, the AI alerts operators immediately—preventing costly mistakes. For example, an AI system might detect that the barrel temperature is rising too fast and automatically adjust it, avoiding burned rubber.

Yigu Technology’s Perspective on Rubber Injection

At Yigu Technology, we believe rubber injection is more than a manufacturing process—it’s a tool to create reliable, innovative products that meet modern industry needs. Over the years, we’ve worked with clients in automotive, medical, and electronics to optimize their rubber injection workflows, and we’ve seen first-hand how the process drives efficiency and quality.

We prioritize sustainability in our projects—whether it’s using recycled rubber compounds or retrofitting machines with energy-saving parts. We also emphasize precision: Our team uses advanced mold design software and AI monitoring to ensure parts meet even the tightest tolerances (down to ±0.01mm).

For businesses considering rubber injection, our advice is simple: Start small. Test your design with a few sample parts, adjust parameters like temperature and pressure, and partner with a supplier who understands your end use. Rubber injection has a learning curve, but the long-term benefits—faster production, less waste, better parts—are worth it.

FAQ About Rubber Injection

1. How much does a rubber injection machine cost?

Entry-level machines for small parts (e.g., O-rings) cost \(50,000-\)100,000. Industrial machines for large parts (e.g., automotive seals) can cost \(200,000-\)500,000. Used machines are cheaper (30-50% less) but may need maintenance.

2. Can rubber injection make parts with complex shapes?

Yes! Rubber injection excels at complex shapes—including parts with undercuts (parts that have a “lip” or indentation), tiny holes, or multiple colors. The key is a well-designed mold with proper vents and gates.

3. How long does it take to set up a rubber injection project?

Setup time depends on mold complexity and material preparation. For a simple mold (e.g., a basic O-ring), setup takes 1-2 days. For a complex mold (e.g., a medical device part), setup can take 1-2 weeks (including testing samples).

4. Is rubber injection suitable for small production runs?

It depends on cost. For runs of fewer than 1,000 parts, compression molding is cheaper (lower upfront mold costs). For runs of 1,000+ parts, rubber injection becomes more cost-effective because of lower per-unit costs and less waste.

5. What are the most common defects in rubber injection, and how to fix them?

- Air Bubbles: Caused by poor venting. Fix: Add more vents to the mold.

- Flash (Excess Rubber): Caused by too much pressure or a poorly sealed mold. Fix: Reduce injection pressure or replace worn mold seals.

- Warped Parts: Caused by uneven cooling. Fix: Add cooling channels to the mold or adjust mold temperature.

- Brittle Parts: Caused by overheating the rubber. Fix: Lower the barrel temperature or reduce curing time.