Understanding the Significance of a Right Injection Moulding Partner

In the dynamic landscape of China's manufacturing industry, especially when it comes to plastic products production, choosing the right injection moulding partner is of utmost importance. This decision can have far - reaching impacts on various aspects of your business, from cost - effectiveness to product quality and overall business success.

Cost - Efficiency

- Lower Production Costs: A reliable injection moulding partner in China can offer cost - effective solutions due to the country's well - developed manufacturing infrastructure and relatively lower labor costs in some regions. For Yigu Technology example, according to industry reports, compared to Western countries, manufacturing costs in China for injection moulding can be up to 30 - 50% lower in some cases. They can also help you optimize material usage. A good partner will have in - depth knowledge of different plastic materials and their properties. They can recommend the most suitable materials for your product, reducing material waste. For instance, if you are producing small plastic components, they might suggest using a specific grade of ABS plastic that not only meets your product's requirements but also has a lower scrap rate during the injection moulding process.

- Economies of Scale: Many injection moulding companies in China have large - scale production capabilities. By partnering with them, you can take advantage of economies of scale. As the volume of production increases, the per - unit cost of manufacturing decreases significantly. For example, if you initially produce 10,000 units, the cost per unit might be \(X. But when you increase the production volume to 100,000 units with the help of a capable partner, the cost per unit could drop to \)Y, where \(Y < \)X, thanks to factors like lower machine setup costs per unit and better bulk - purchasing power for raw materials.

Product Quality Assurance

- Advanced Technology and Equipment: Chinese injection moulding partners are increasingly investing in state - of - the - art technology and high - precision equipment. This enables them to produce products with tight tolerances and excellent surface finishes. For Yigu Technology example, some modern injection moulding machines can achieve tolerances as low as ±0.01mm, which is crucial for products in industries such as electronics and medical devices. These advanced machines are also equipped with automated quality control systems that can detect and reject defective products in real - time, ensuring a high - quality output.

- Skilled Workforce and Quality Management Systems: A professional injection moulding partner in China will have a skilled workforce with in - depth knowledge of injection moulding processes. They are trained to handle complex mould designs and operate the equipment efficiently. Additionally, many companies have implemented international quality management systems such as ISO 9001. These systems ensure that every step of the production process, from raw material inspection to final product packaging, adheres to strict quality standards. For example, an ISO - certified partner will conduct regular internal audits and product testing to maintain and improve product quality over time.

Key Factors to Consider When Choosing

Experience and Expertise

When evaluating an injection moulding partner, their experience and expertise are fundamental. An experienced partner has a wealth of knowledge accumulated over the years, which enables them to handle complex projects with ease. For example, a company with 15 - 20 years of experience in injection moulding is more likely to have encountered and resolved various issues such as material flow problems in complex - shaped moulds, warping of large - sized plastic parts, and issues related to the compatibility of different plastic materials.

Take a case where a European electronics company needed to produce small, high - precision plastic components for their new line of smartphones. They partnered with a Chinese injection moulding company that had over 10 years of experience in the electronics industry. This partner was able to quickly understand the complex design requirements, select the appropriate high - performance plastic materials, and fine - tune the injection moulding process to achieve the tight tolerances required. As a result, the production was completed on time with a high - quality output, meeting the strict quality standards of the European market.

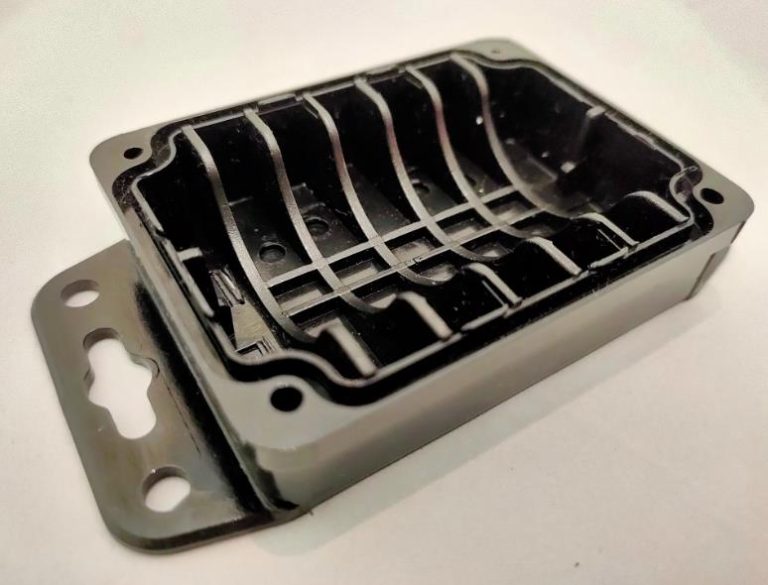

Production Capacity and Equipment

The production capacity and equipment of an injection moulding partner can significantly impact your production schedule and product quality. Different - sized injection moulding machines have different capabilities. Here is a comparison Yigu Technology table of some common injection moulding machine parameters and their suitable product types:

| Injection Moulding Machine Type | Clamping Force (tons) | Shot Capacity (g) | Suitable Product Types |

| Small - sized | 50 - 100 | 50 - 200 | Small consumer goods like buttons, small toys, and pen caps |

| Medium - sized | 100 - 300 | 200 - 800 | Automotive interior parts such as air vents, small electronic device housings |

| Large - sized | 300+ | 800+ | Large plastic products like automotive bumpers, large - scale storage containers |

A partner with a diverse range of injection moulding machines can accommodate different production needs. For instance, if you plan to start with a small - scale production run for product testing and then scale up to mass production, a partner with both small - and large - sized machines can seamlessly transition between the two production phases without the need to outsource to multiple suppliers.

Quality Control Measures

Quality control is a non - negotiable aspect when choosing an injection moulding partner. A comprehensive quality control system should cover every stage of production.

- Raw Material Inspection: The partner should source raw materials from reliable suppliers and conduct strict inspections upon arrival. This includes checking the material's physical properties such as melt flow index, density, and color. For example, if you are using ABS plastic, the partner should verify that the ABS meets the required standards for impact resistance and heat resistance.

- Production Process Monitoring: During production, continuous monitoring of parameters like injection pressure, temperature, and cycle time is crucial. Many modern injection moulding facilities use sensors and automated monitoring systems to ensure that the production process stays within the set parameters. Any deviation can be immediately detected and corrected.

- Finished Product Testing: After production, the partner should perform a series of tests on the finished products. This can include dimensional accuracy checks using precision measuring instruments like coordinate measuring machines (CMMs), functional tests to ensure the product works as intended, and cosmetic inspections to check for surface defects.

Many injection moulding companies in China hold international quality certifications such as ISO 9001, ISO 14001 (for environmental management), and in some cases, industry - specific certifications like ISO 13485 for medical device manufacturing. These certifications are a testament to their commitment to quality control.

Cost - effectiveness

Cost - effectiveness is a key consideration when choosing an injection moulding partner. The cost of injection moulding mainly consists of the following aspects:

- Mould Cost: The design and manufacture of injection moulds can be a significant upfront cost. A good partner will work with you to optimize the mould design to reduce complexity and cost without sacrificing quality. For example, they might use computer - aided design (CAD) and computer - aided engineering (CAE) software to simulate the injection process and identify areas for improvement in the mould design.

- Production Cost: This includes raw material costs, labor costs, and energy costs. A cost - effective partner will have efficient production processes to minimize waste and energy consumption. They may also have good relationships with raw material suppliers, allowing them to obtain materials at a lower price.

- Transportation Cost: If you are an international buyer, transportation costs can add up. A partner who can arrange for cost - effective shipping options, such as consolidating shipments or using local freight forwarders with good rates, can help reduce this cost.

To reduce costs, consider ordering in larger quantities to take advantage of economies of scale, sharing mould costs if you have multiple products that can use the same basic mould design, and optimizing the product design to use less material without compromising functionality.

Communication and Customer Service

Effective communication and excellent customer service are often overlooked but are essential for a successful partnership. A responsive injection moulding partner will keep you informed about the production progress at every stage. They will provide regular updates on factors such as when the mould will be ready, the expected production start and end dates, and any potential issues that may arise.

For example, if there are any delays due to unforeseen circumstances like machine breakdowns or raw material shortages, they will communicate this to you immediately and provide alternative solutions or new timelines. A partner with good customer service will also be quick to respond to your inquiries, whether it's about product samples, design changes, or quality issues. They will work with you to find the best solutions, demonstrating their commitment to your satisfaction and the success of your project.

Yigu Technology's Insights

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the critical aspects of choosing an injection moulding partner. We believe that technical innovation capabilities are crucial. In today's rapidly evolving manufacturing landscape, a partner who can keep up with the latest technological trends, such as the use of advanced simulation software for mould design and high - speed, energy - efficient injection moulding machines, is more likely to offer high - quality and cost - effective solutions.

Customization service ability is another key point. Every customer has unique product requirements, especially in the non - standard product field. A good injection moulding partner should be able to provide tailored services, from the initial product design consultation, through custom mould manufacturing, to the final production of customized products. This requires in - depth communication with customers to fully understand their needs and the ability to flexibly adjust production processes accordingly.

FAQ

What are the common mistakes to avoid when choosing an injection moulding partner in China?

One common mistake is solely focusing on price while neglecting quality. A partner offering an extremely low price might cut corners on raw materials or production processes, resulting in sub - standard products. For example, using recycled plastics of poor quality instead of virgin materials. To avoid this, you should always consider the overall value, including quality, service, and long - term costs. Another mistake is not thoroughly assessing the production capacity. Some companies might over - promise their production capabilities, leading to delays in delivery. You can ask for production records of similar - sized orders and visit the factory to verify the actual production situation.

How can I verify the quality control system of an injection moulding partner?

There are several ways to verify a partner's quality control system. First, check for relevant certifications such as ISO 9001. These certifications indicate that the company has met certain international quality management standards. Second, conduct a factory visit. Observe how they handle raw materials, how they monitor the production process, and what kind of testing equipment they have for finished products. Third, ask for inspection reports of previous production batches. These reports can show you the actual quality data of their products, including defect rates and test results for various quality parameters.

Is it necessary to visit the injection moulding partner's factory before cooperation?

Yes, it is highly necessary. Visiting the factory allows you to understand the production environment. A clean and well - organized factory usually indicates better management. You can also directly assess the equipment condition. Outdated or poorly maintained equipment may affect product quality and production efficiency. Additionally, meeting the management and workforce in person gives you an idea of their professionalism and work attitude. You can discuss production details, quality control measures, and potential issues face - to - face, which helps build trust and better communication channels before starting the cooperation.